Electrochemical method for removing biological pollution of ocean ship

A bio-pollution, electrochemical technology, applied to the device, application, and animal husbandry of catching or killing insects, which can solve the problems of short effective period, increased cost, and large demand, and achieves simple and easy steps and high electric shock intensity. Large and good decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

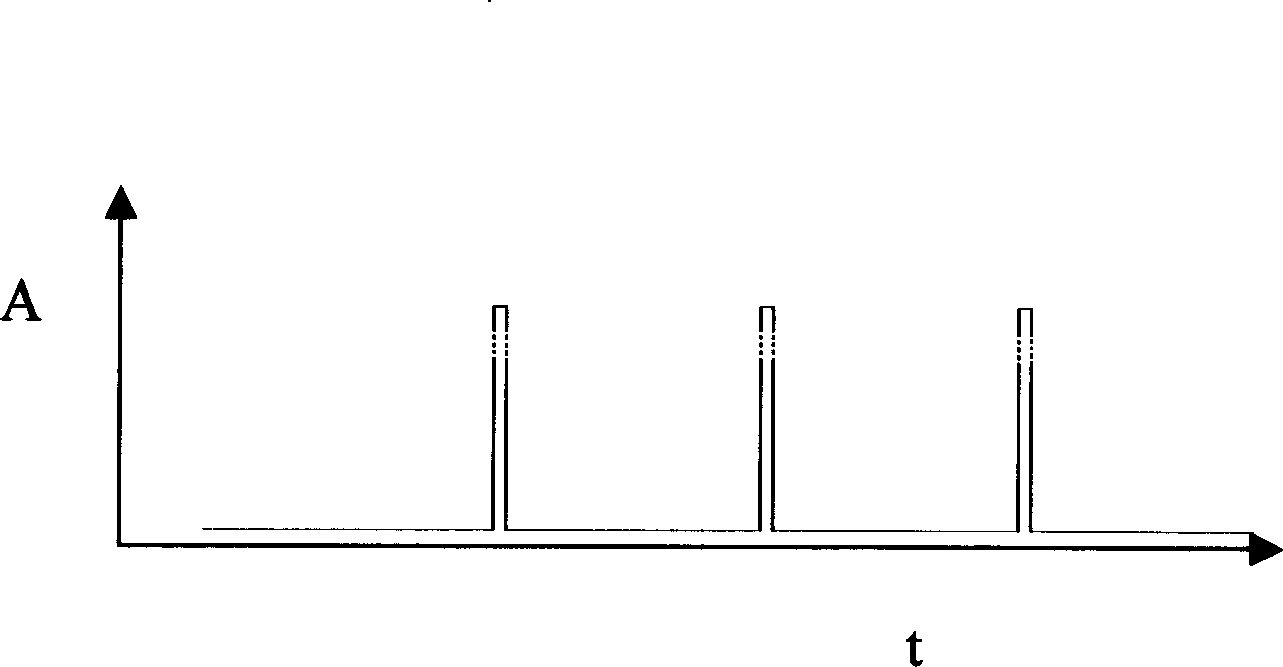

[0027] Embodiment 1: as Figure 4 Anode rod shown, according to image 3As shown, it is connected to the pulse power supply, the conductor in the anode 2 is made of flexible graphite rod, and its size is: 20mm in diameter, 500mm in length, the surface of the conductor is covered with a layer of insulating plastic, polyethylene is selected, and the thickness of the plastic coating layer 11 is 1mm, there are many holes 9 on the insulating plastic, which are 1mm×2mm rectangular holes with an interval of 10mm, distributed on one side of the electrode body, the conductor can contact with seawater through these holes, and the discharge current is also released through these holes, operation One end of the rod 5 is connected to the conductor 10 through the connecting rod 8, and the connecting rod is fixed on the operating rod 5, or is a part of the operating rod. The joystick can be manually or mechanically controlled.

[0028] The pulse current reaches the conductor 10 through the...

Embodiment 2

[0029] Embodiment 2, the electric conductor in embodiment 1 is changed into the square titanium plate that area is 1 square meter, is 4mm thick, is coated with one deck insulating plastic (polyvinyl chloride) equally, and is 2mm thick, towards the hull side Holes with a diameter of 1 cm and an interval of 4 cm are evenly distributed on the plastic, and the titanium plate can be seen through the holes. The center of the other side of the plate is welded together with the connecting rod. The holed side of the anode plate touches the surface of the seriously fouled hull that has absorbed sea oysters. The cathode is connected to the hull, and a pulse current with a peak value of 100A is applied for a duration of 1 Seconds, the interval time is 5 seconds, it can also be seen that sea oysters are shot down, and gas is generated, so as to remove biological pollution from marine ships.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com