Chemical plating liquid for preparing high temperature self lubricating composite coating and chemical plating method

A high-temperature self-lubricating, chemical plating solution technology, applied in liquid chemical plating, coating, metal material coating technology and other directions, can solve the problems of short service life and low operating temperature, and achieve good bonding force and extended working life. , composition and simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

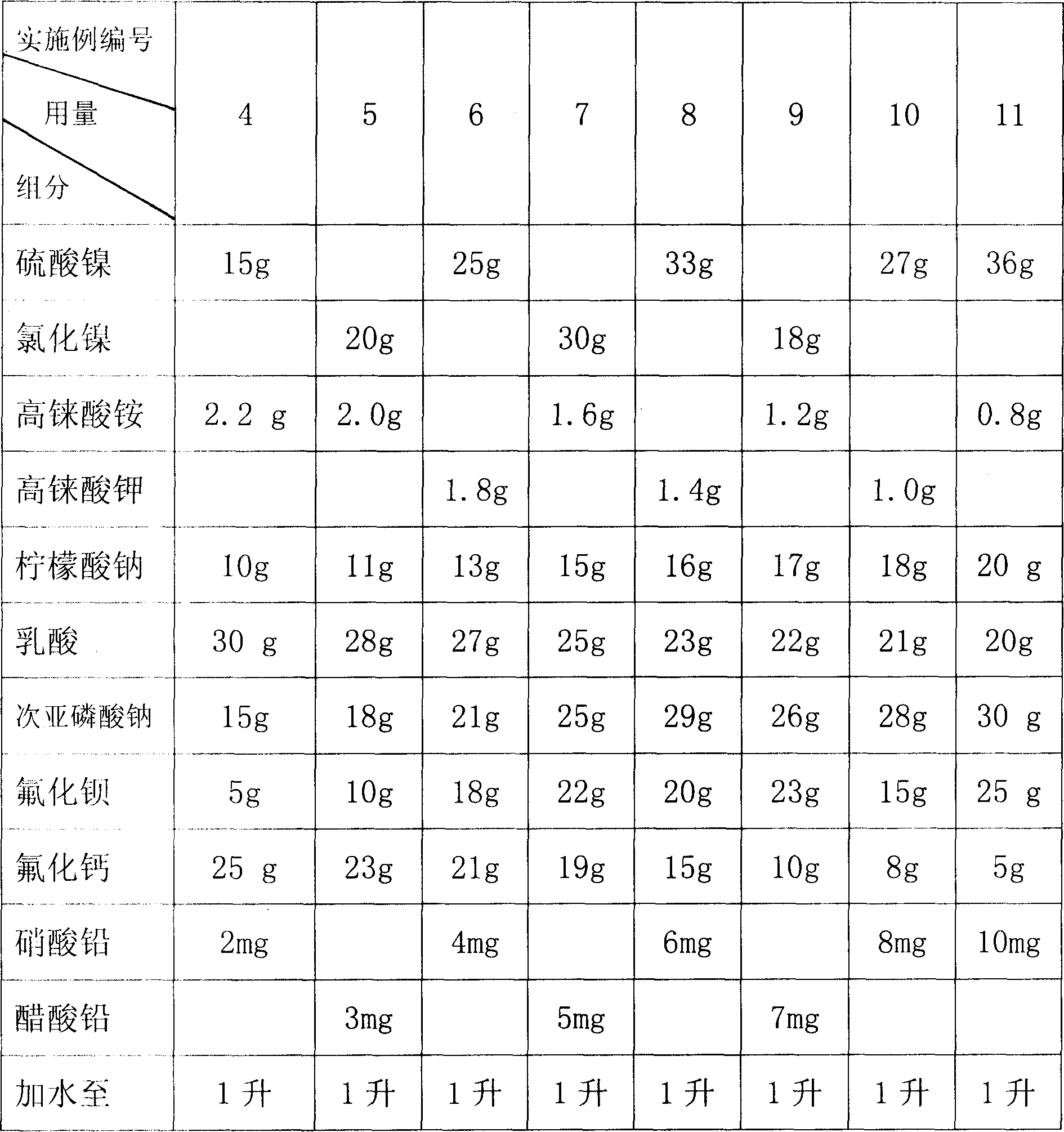

Examples

Embodiment 1

[0031] A kind of chemical plating solution for preparing high-temperature self-lubricating composite coating, the composition and content of every 1 liter (L) chemical plating solution are:

[0032] Nickel Sulfate NiSO 4 ·7H 2 O 36g,

[0033] Potassium perrhenate KReO 4 2.2g

[0034] Sodium citrate Na 3 C 6 h 5 o 7 2H 2 O 20g

[0035] Lactic acid C 3 h 6 o 3 30g

[0036] Sodium Hypophosphite NaH 2 PO 4 30g

[0037] Barium fluoride BaF 2 25g

[0038] Calcium Fluoride (CaF) 2 25g

[0039] Lead nitrate Pb(NO 3 ) 2 10 mg.

[0040] The preparation method of above-mentioned electroless plating solution is:

[0041] 1. Weigh the metered nickel sulfate (NiSO 4 ·7H 2 O) or nickel chloride (NiCl 2 ·6H 2 O), ammonium perrhenate (NH 4 ReO 4 ) or potassium perrhenate (KReO 4 ), sodium citrate (Na 3 C 6 h 5 o 7 2H 2 ...

Embodiment 2

[0048] An electroless plating solution for preparing a high-temperature self-lubricating composite coating, the composition and content of every 1 liter (L) of the electroless plating solution are: nickel chloride (NiCl 2 ·6H 2 O) 15g, potassium perrhenate (KReO 4 ) 0.8g, sodium citrate (Na 3 C 6 h 5 o 7 2H 2 O) 10g, lactic acid (C 3 h 6 o 3 )20g, sodium hypophosphite NaH 2 PO 4 15g, barium fluoride (BaF 2 )5g, calcium fluoride (CaF 2 )5g, lead acetate (Pb(AC) 2 ) 2 mg, add water (preferably distilled water or deionized water) to 1 liter. The dipping pH value is 5, the temperature is 85°C, and the plating time is 10 to 60 minutes. Others are the same as in Example 1, omitted.

Embodiment 3

[0050] An electroless plating solution for preparing a high-temperature self-lubricating composite coating, the composition and content of every 1 liter (L) of the electroless plating solution are: nickel sulfate NiSO 4 ·7H 2 O 25g, ammonium perrhenate (NH 4 ReO 4 ) 1.5g, sodium citrate (Na 3 C 6 h 5 o 7 2H 2 O) 15g, lactic acid (C 3 h 6 o 3 )22g, sodium hypophosphite NaH 2 PO 4 22g, barium fluoride (BaF 2 ) 16g, calcium fluoride (CaF 2 ) 16g, lead nitrate (Pb(NO 3 ) 2 ) 5 mg, add water (preferably distilled water or deionized water) to 1 liter. The dipping pH value is 7, the temperature is 95°C, and the plating time is 10 to 60 minutes. Others are the same as in Example 1, omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com