Method for co-producing hydrogen and methane by biomass and solid organic waste fermenting method

A technology of organic waste and biomass, applied in fermentation, waste fuel, chemical recycling, etc., can solve the problems of low conversion rate of pure hydrogen production energy, low conversion rate of hydrogen production energy, and gasification rate of less than 4%. To achieve the effect of resource utilization, good economic and social benefits, and improvement of energy conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

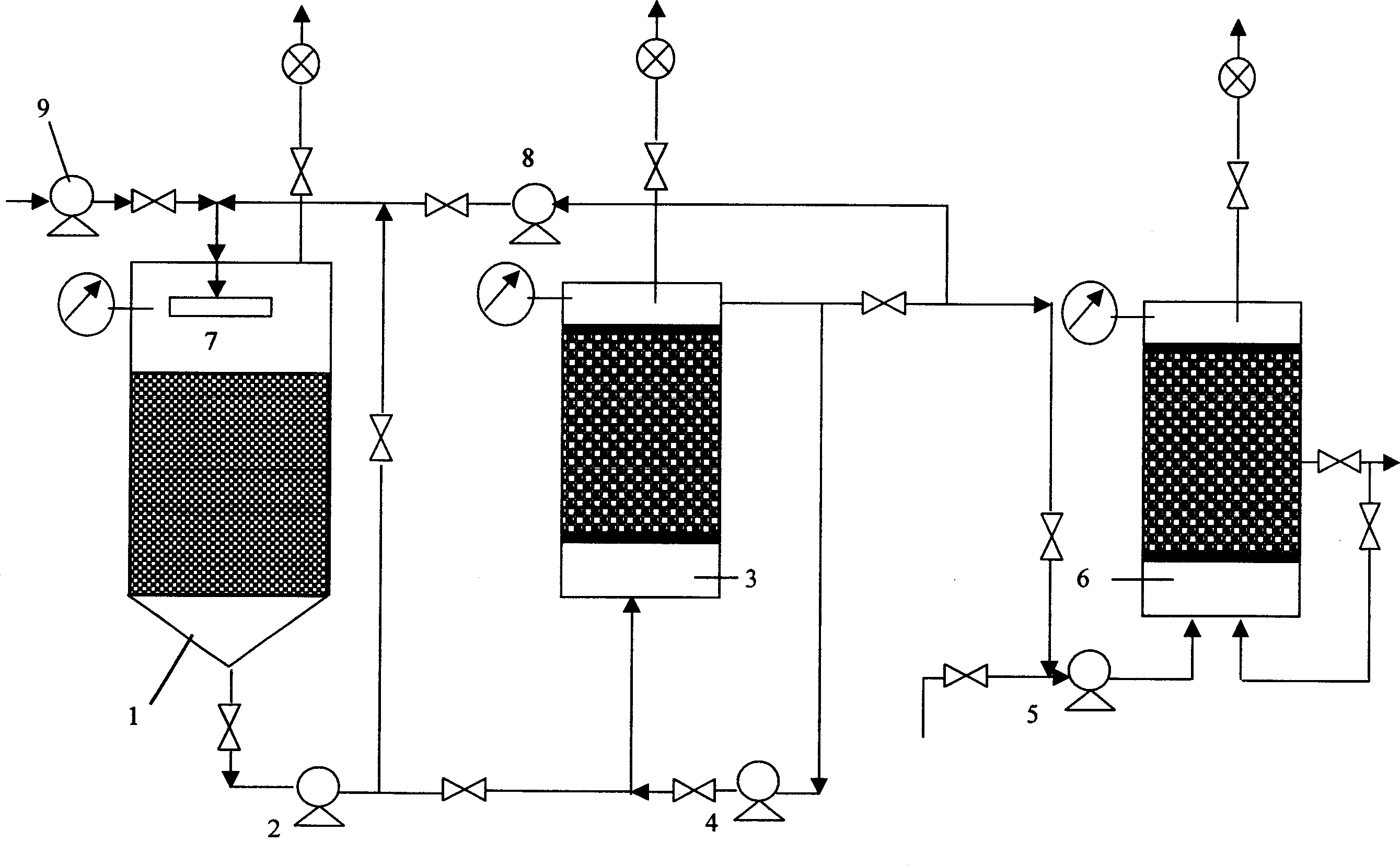

Method used

Image

Examples

specific Embodiment 1

[0031] (1) Collect anaerobic activated sludge from urban sewage treatment plants, boil it under water-sealed conditions, inoculate it in culture medium, and acclimate it in a constant temperature incubator for 7 days to obtain a large number of fermentative hydrogen-producing bacteria as inoculum. The crushed potato is used as the fermentation base material, and it is hydrolyzed at a temperature of 35°C and a pH value of 5.0 to produce soluble sugars, amino acids and long-chain fatty acids;

[0032] (2) Acidify the mixture obtained after the above hydrolysis at a temperature of 35°C and a pH value of 5.0 to generate pyruvic acid, short-chain fatty acids and a small amount of H 2 , CO 2 ;

[0033] The hydrolysis reaction and acidification reaction of this step are carried out in same hydrolysis and acidification reactor; Reaction efficiency.

[0034] (3) Under the action of fermentative hydrogen-producing bacteria such as Clostridium butyricum, the mixture of pyruvic acid an...

specific Embodiment 2

[0039] The steps of this embodiment are the same as those in Example 1, wherein:

[0040] In step (1) the controlled temperature in the hydrolysis reaction is 30°C, and the pH value is 4.5; in the step (2) the controlled temperature in the acidification reaction is 30°C, and the pH value is 4.5; in the step (3) the controlled temperature in the hydrogen production reaction is 30°C, The pH value is 4.5; in step (4) in the methanogenic reaction, the temperature is controlled to be 30° C., and the pH is 7.0.

specific Embodiment 3

[0041] The steps of this embodiment are the same as those in Example 1, wherein:

[0042] In step (1) the controlled temperature in the hydrolysis reaction is 60°C, and the pH value is 7.0; in the step (2) the controlled temperature in the acidification reaction is 60°C, and the pH value is 7.0; in the step (3) the controlled temperature in the hydrogen production reaction is 60°C, The pH value is 7.0; in step (4) in the methanogenic reaction, the temperature is controlled to be 60° C., and the pH is 8.0.

[0043] Bacteria or strains used in the present invention are existing known strains, for example, fermenting hydrogen-producing bacteria (clostridium butyricum), methanogenic bacteria (methanosarcini), wherein fermenting hydrogen-producing bacteria (clostridium butyricum Bacteria) is a large number of bacteria carried by the anaerobic activated sludge itself. Methanosarcina is a commercially available strain. For example, Methanosarcina acetophilus produced by Soochow Unive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com