Composite process for bending and punching external protecting ring of steel reel and moulds thereof

A technology for punching punches and steel coils, which is applied in the field of steel coil outer retainer bending, punching compound technology and molds, which can solve the problems of high production cost, labor and time-consuming, complicated process, etc. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

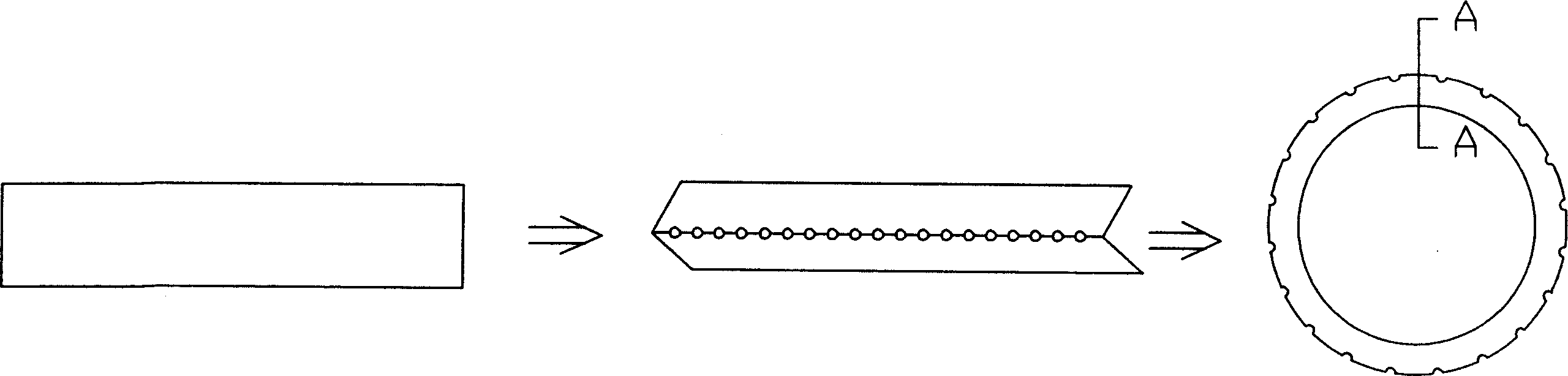

[0024] Now give an embodiment of the composite process of bending and punching the steel coil outer retainer of the present invention, and its steps are as follows:

[0025] 1. Coil the steel strip into a steel strip, the size of which is 4000mm long and 140mm wide.

[0026] 2. The strip steel strip is bent and formed, and the angle of the bending is 88°. At the same time, 20 holes are punched, and the distance between each hole is equal. Of course, it is okay to be slightly different.

[0027] 4. Finally, use the angle steel machine to round the angle steel material.

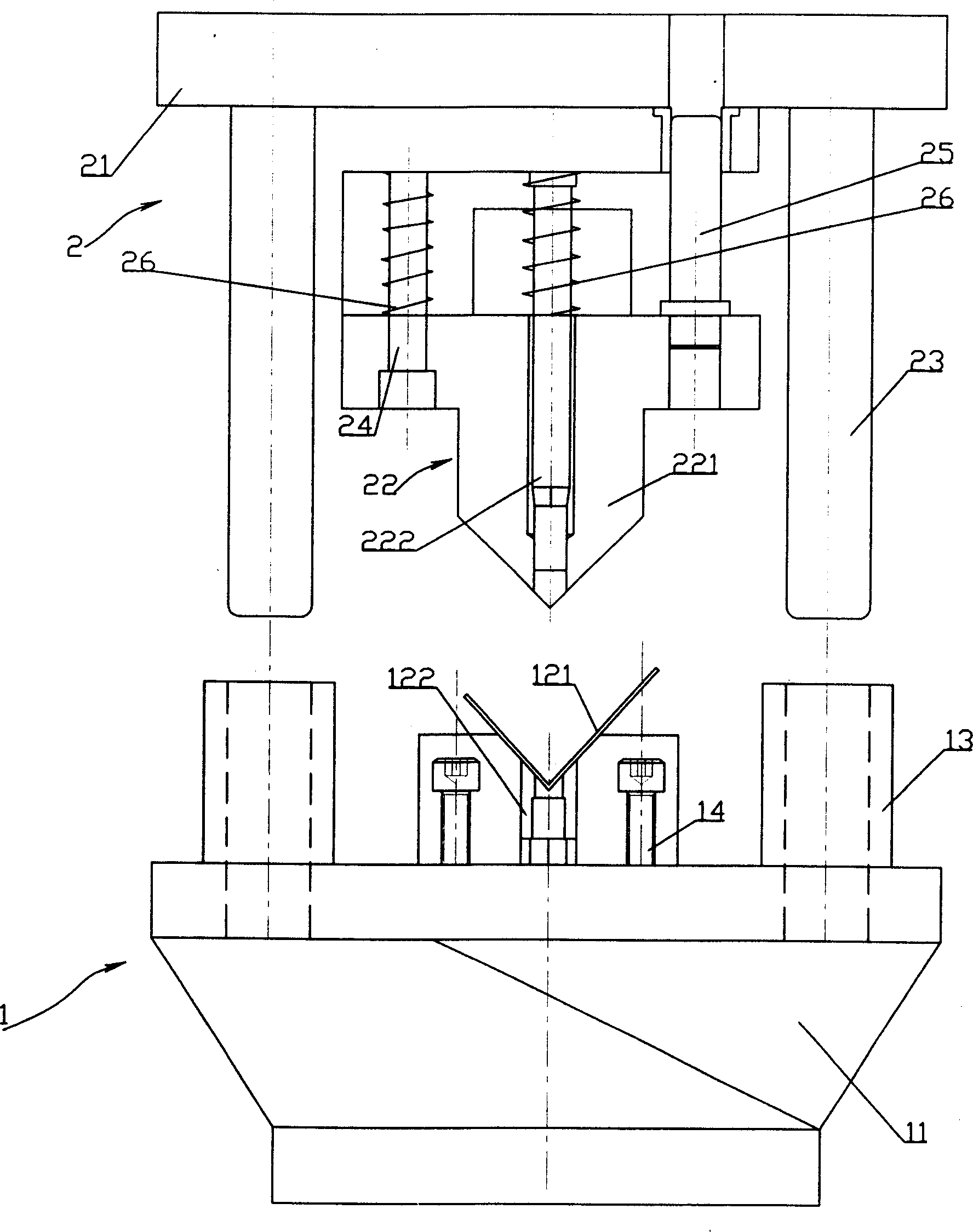

[0028] The mold of the present invention is a special mold for manufacturing the outer retaining ring of steel coils. It can bend and shape strip steel strips. The angle of bending is 88°. At the same time, 20 holes are punched, and the distance between each hole is the same. The whole process Can be done in one stamping process. The mold of this embodiment is composed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com