Symmetric-structure double-grade decoupling single-crystal-silicon micro mechanical gyroscope

A silicon micromechanical and symmetrical structure technology, applied in the field of inertial measurement, can solve the problems of reducing the long-term reliability of the system and increasing the cost of the device, and achieve the effect of easy matching of resonant frequency and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Hereinafter, the present invention will be described in more detail with examples in conjunction with the accompanying drawings:

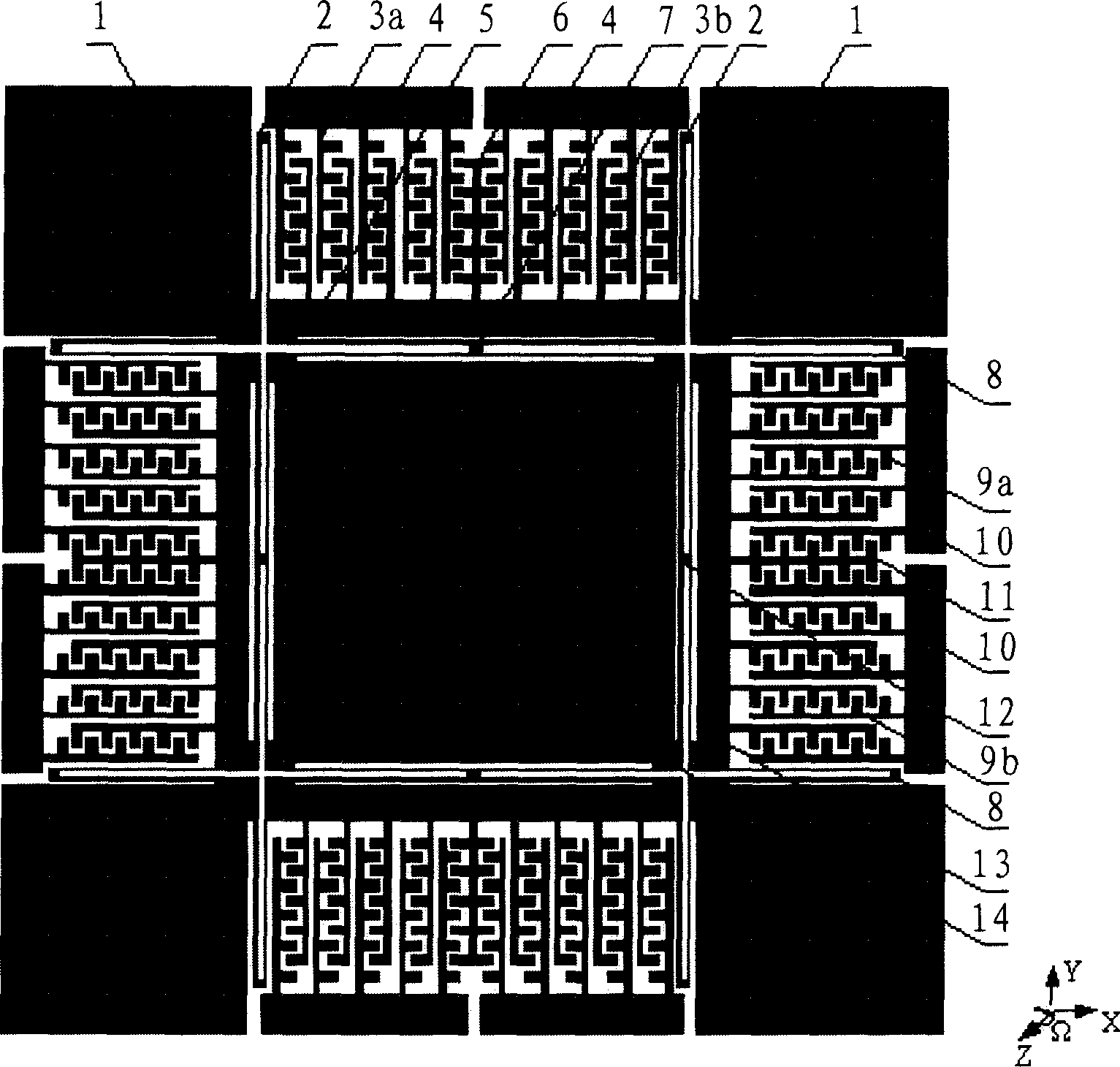

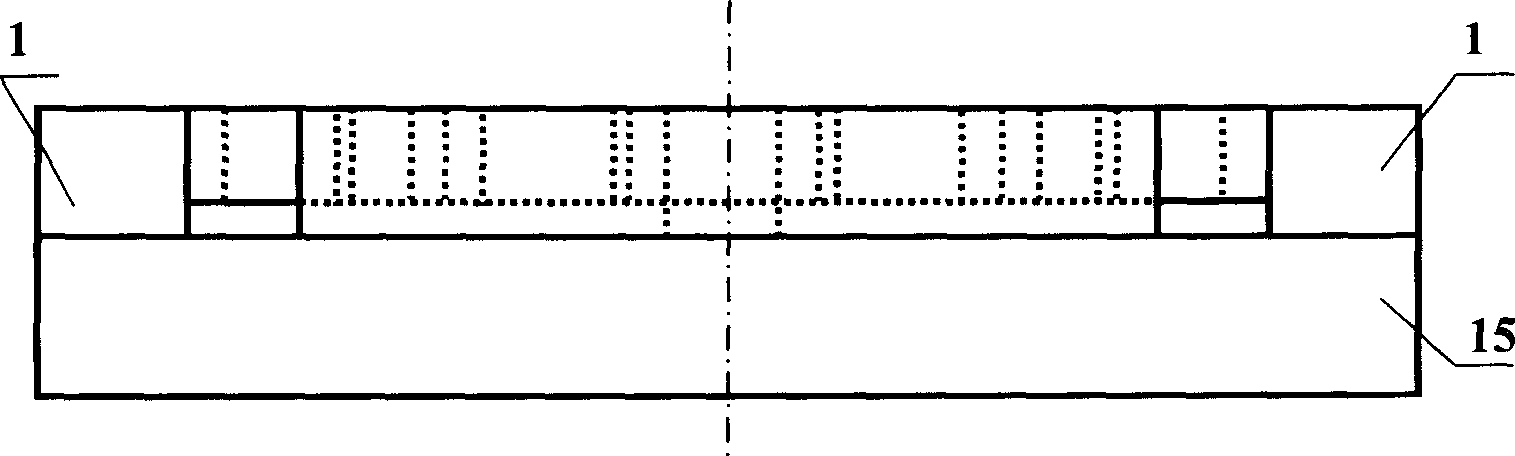

[0016] Combine figure 1 with figure 2 It includes a glass substrate 15, a metal electrode sputtered on the glass substrate, a silicon wafer bonded to the glass substrate through the integral bonding area 1, a driving fixed electrode bonding area 4, a detection fixed electrode bonding area 10, and The structure etched on the silicon chip includes a mass block 14 in the middle, comb drivers symmetrically distributed on both sides of the mass block, comb detectors symmetrically distributed on the other two sides of the mass block, and drive fixed electrodes 3a, 3b is connected with the driving fixed electrode bonding area, the detection fixed electrodes 9a, 9b are connected with the detection fixed electrode bonding area, the driving movable electrode 6 is connected with the driving frame 5, and there is a detection decoupling beam 7 between the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com