Column-hammer strong-tamper displacing base kit supporting construction method

A technology of dynamic compaction replacement and dynamic compaction replacement of piers, which is applied in infrastructure engineering, artificial islands, water conservancy projects, etc., can solve problems such as difficulty in meeting design requirements, engineering cost, inability to use external precipitation, and long support construction period. , to achieve the effect of improving the compactness, improving the slip stability coefficient, and advancing the support construction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

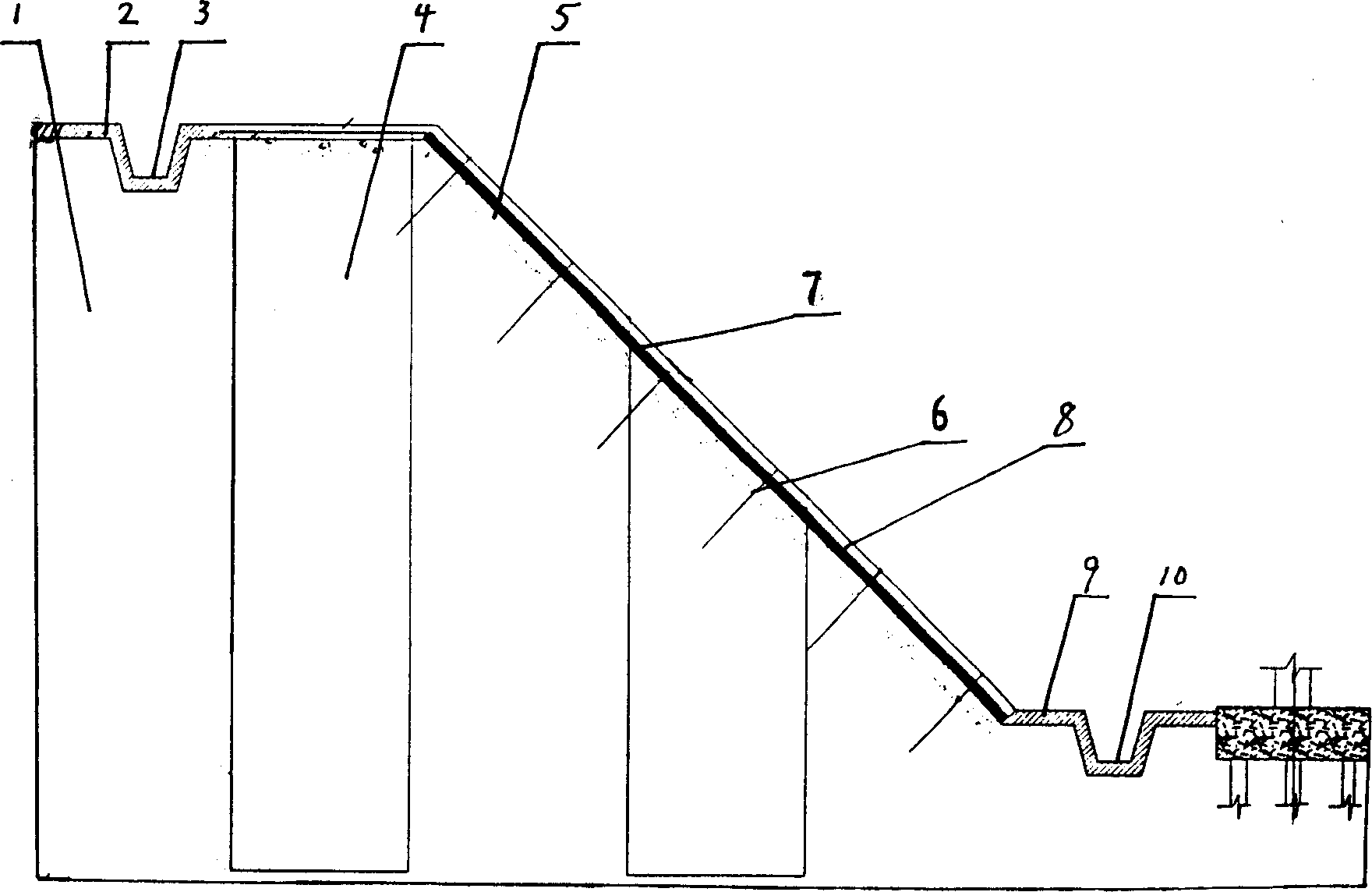

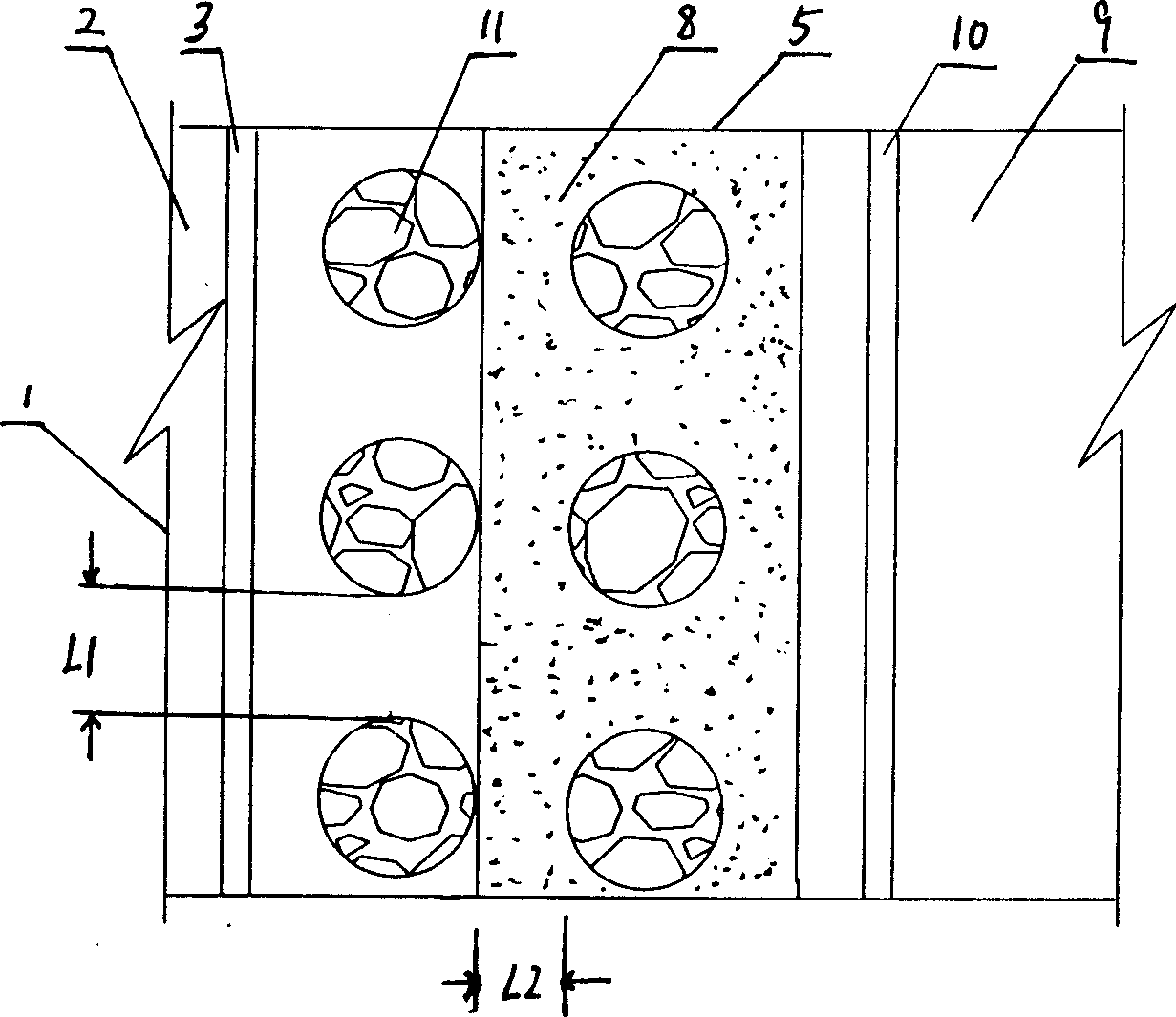

[0026] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

[0027] The construction steps of the new column hammer dynamic compaction replacement foundation pit support method are as follows:

[0028] (1) Site leveling: according to the design elevation, excavate, fill and level the earthwork of the site;

[0029] (2) Laying out points: According to the design requirements, position and set out the wires, and arrange points within the force range of the base according to 1.5-2.0 times the diameter of the hammer bottom to determine the tamping point; between the bases, arrange points within the range of ground reinforcement and expansion tamping Controlled according to stratum conditions and structural design requirements, generally 3-4 times the diameter of the column bottom;

[0030] (3) The tamping points of the first construction pass are deeply replaced and compacted, and a n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com