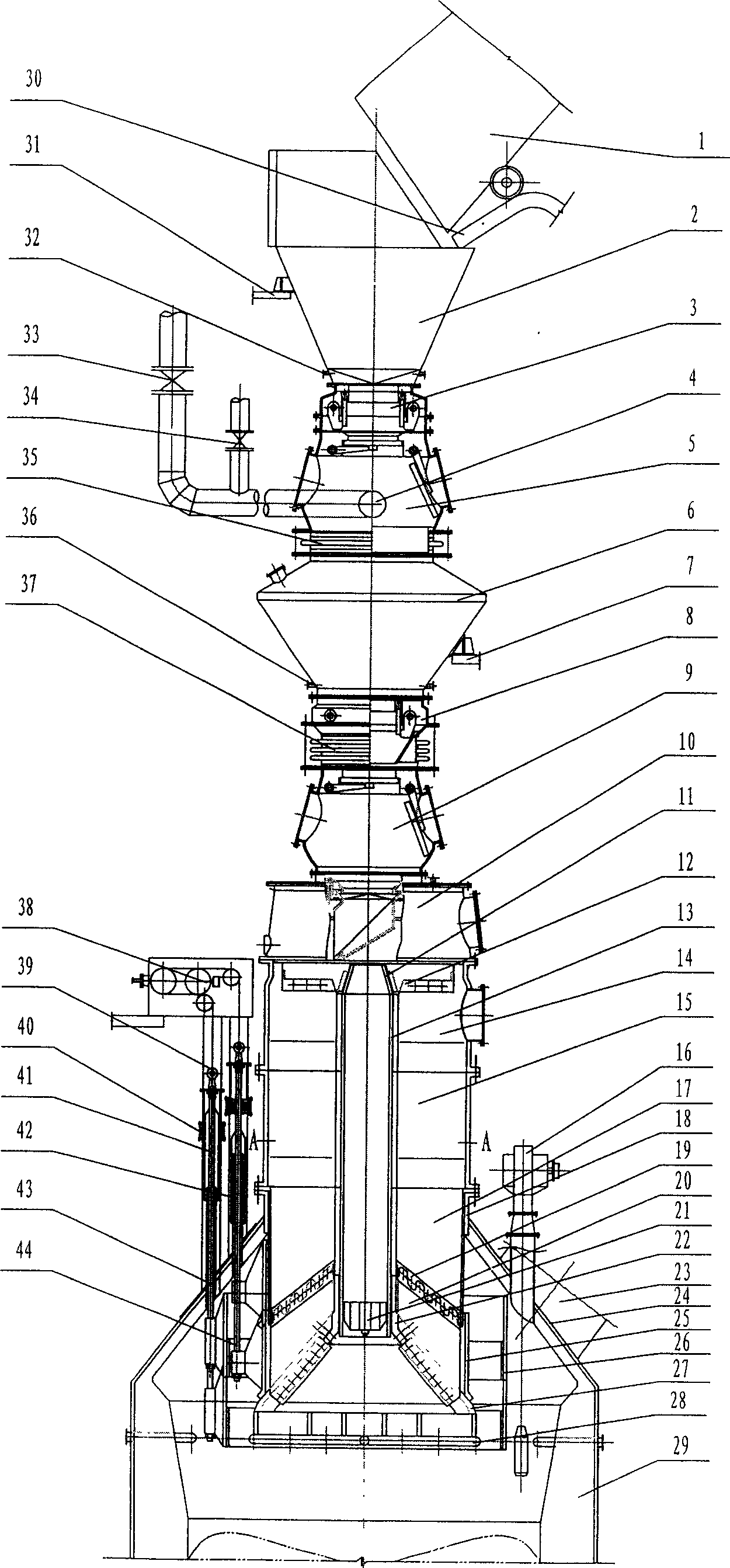

Blast furnace section ore-coke alternating multi-sector step distributing method, and its furnace top device

A furnace top device and cross-section technology, which is applied to the furnace top charging device and the field of blast furnace distribution, can solve the problems of poor air permeability of the material column, poor air permeability and local airflow, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

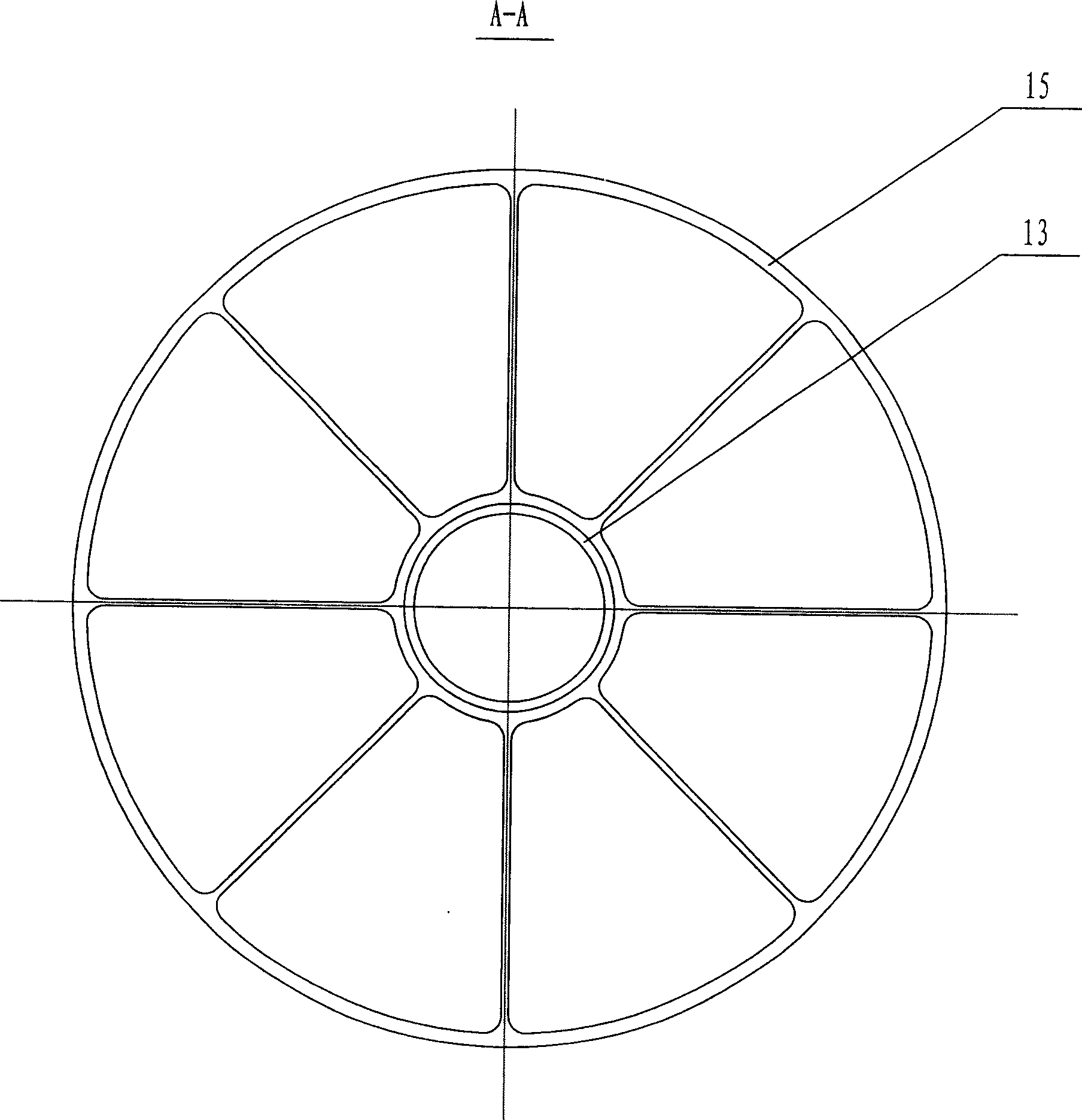

[0016]In practice, the ore and coke are distributed first and then the ore is distributed, and the ore and coke are distributed to the furnace throat by stepping and distributing the ore and coke. When the sealing probe and the TKFL-45 series blast furnace radar probe 16 automatic detection surface When the specified material line is reached, lift the sealed probe to the position ready to probe. At this time, the TKFL-45 series blast furnace radar probe does not need to be lifted; the movable hopper and the movable throat mechanical transmission airtight box 38 are used to lift the movable When the hopper 25 reaches the open position, the movable furnace throat 26 is selected to drop as the movable hopper 25 is lifted or remains in the original position. After a delay of 10 seconds, the coke distributed in the 8-chamber distribution hopper is distributed into the blast furnace throat 29 Delay for 10 seconds until the movable hopper 25 drops to the closed position, and the movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com