Earthworm acidic-part medicine for treating cough asthma disease and preparing method

A technology for acidic parts and cough and asthma, applied in the field of medical engineering, can solve problems such as difficult to effectively control drug quality, difficult to establish drug quality standards, and unclear chemical substance basis of active ingredients, so as to facilitate quality control and clear chemical composition , The effect of facilitating patients to take medication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Screening the effective parts of Dilong antiasthma

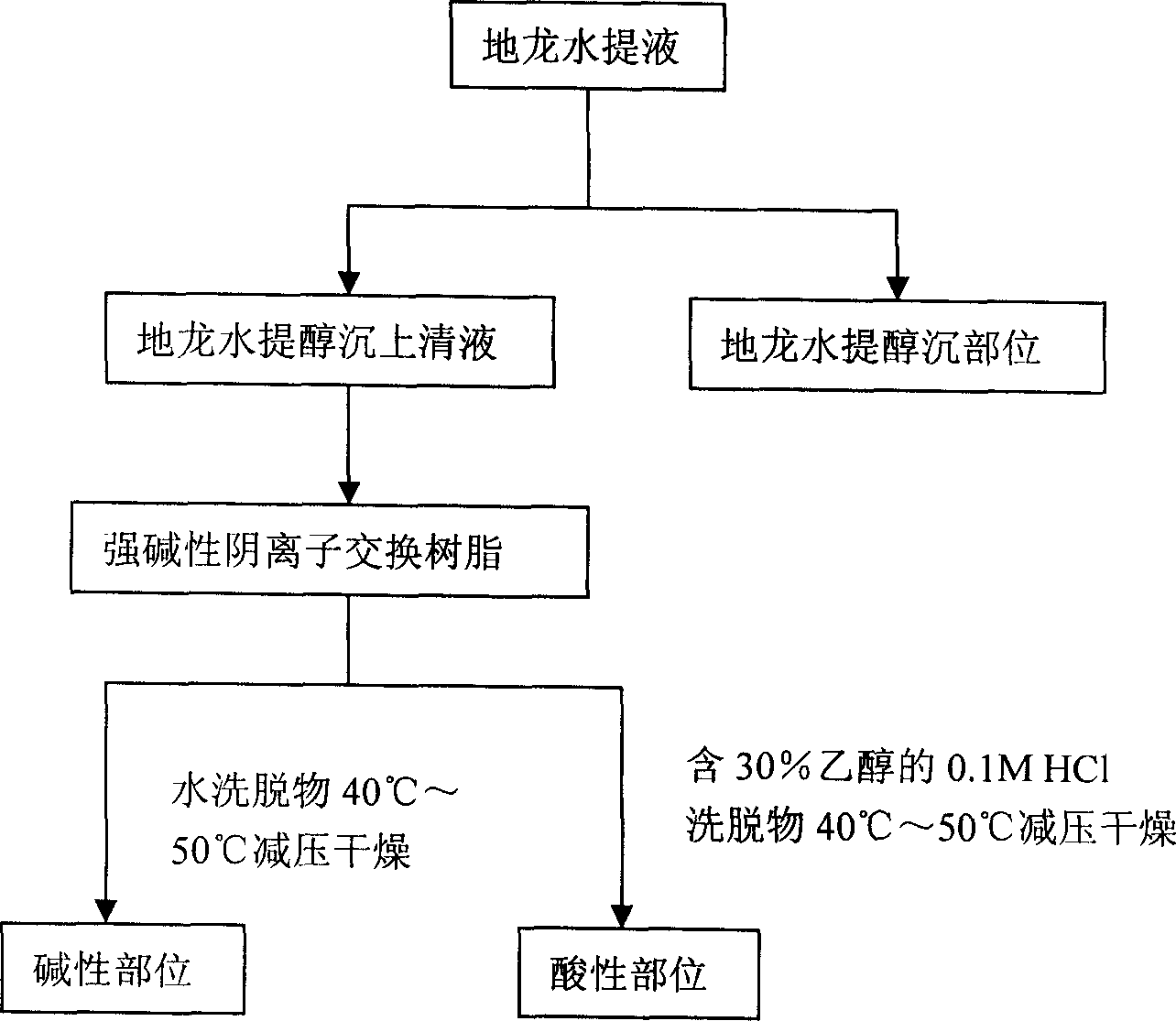

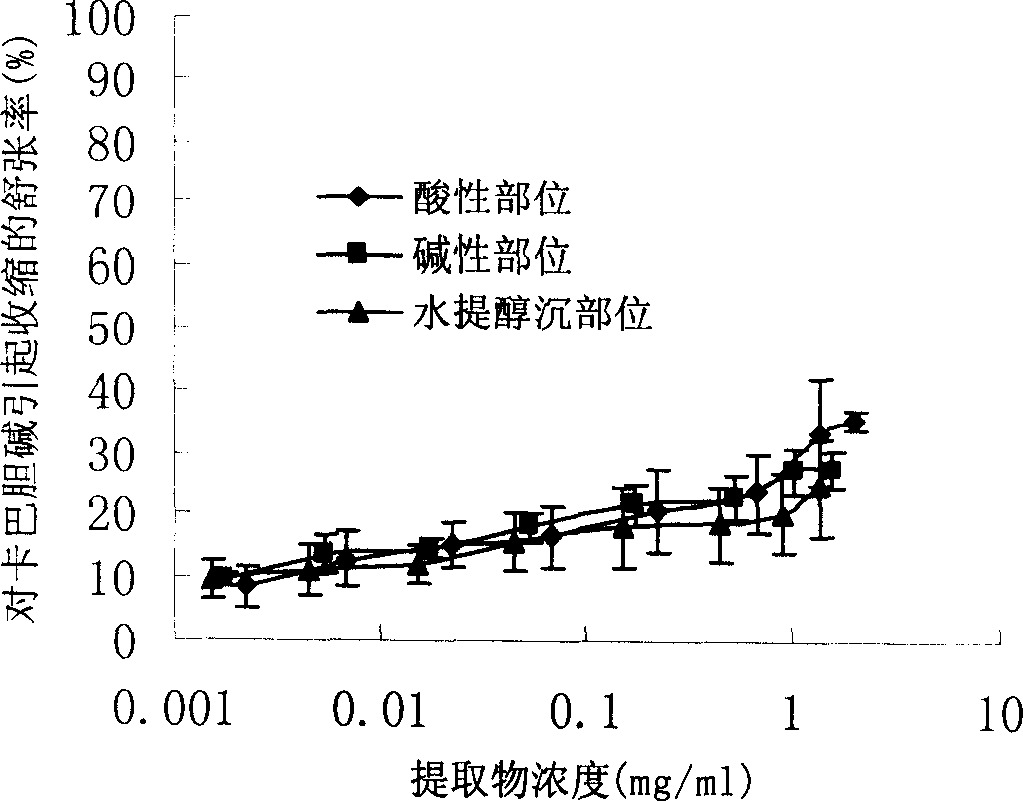

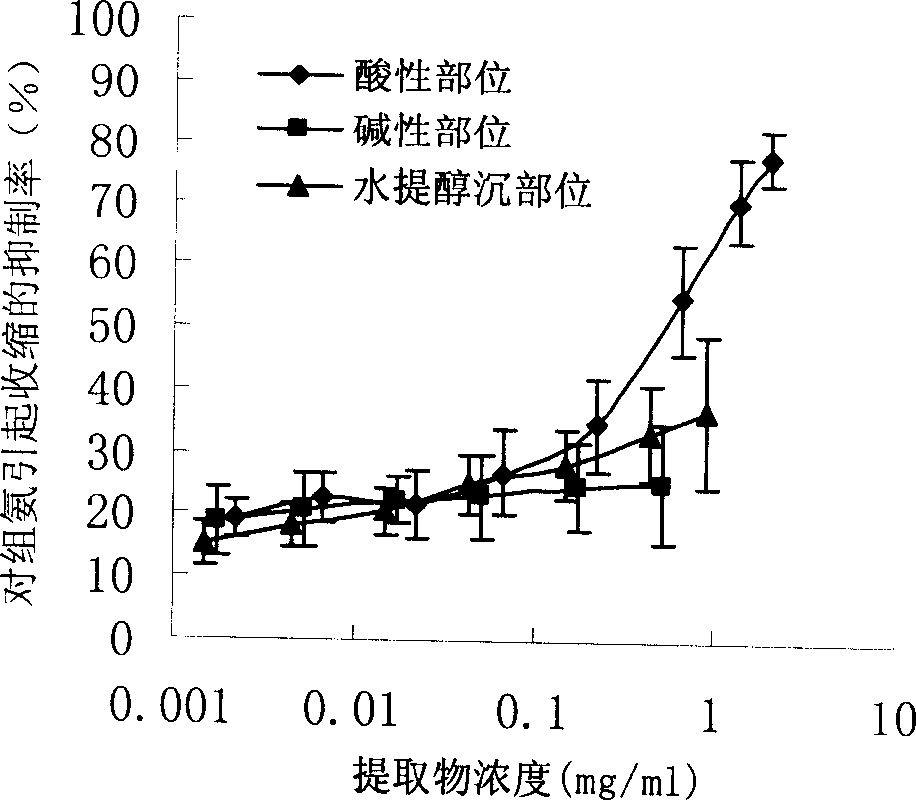

[0023] Three parts of Earthworm were prepared respectively, including the acidic part of Earthworm, the alkaline part of Earthworm, and the water-extracted and alcohol-precipitated part of Earthworm (for the preparation process, see figure 1 ). Then observe the relaxation effect of the three extraction sites on the increase of guinea pig tracheal smooth muscle tension caused by carbachol (CCh) and histamine (His), and the inhibitory effect on the increase of short-circuit current in the rat tracheal epithelium caused by CCh (inhibition of sputum secretion effect). The relaxation effect of 3 earthworm extract parts on tracheal smooth muscle figure 2 and image 3 , the results show that the three kinds of earthworm extract parts have weak relaxation effects on guinea pig isolated tracheal smooth muscle contraction caused by 10μM carbachol, and the acid part of earthworm has the largest relaxation rate, whi...

Embodiment 2

[0026] Example 2 Preparation of acid fraction of earthworm

[0027] Preparation:

[0028] Take 1000g of dried Earthworm, crush it into coarse powder, add 5 times the amount of Earthworm to soak at room temperature for 3 hours, filter; add 4 times the amount of Earthworm to soak in water at 45°C for 2 hours, filter, repeat this operation once, Filtrate, combine the filtrates three times, centrifuge at low speed for 9 minutes, take the centrifuged supernatant, concentrate under reduced pressure to 4 times the volume of the earthworm dosage, then add 95% ethanol to make the alcohol content reach 70%, let it stand for 16 hours, centrifuge, and take the supernatant liquid, the supernatant was concentrated under reduced pressure to 3 times the volume of the earthworm dosage. Pass it through strongly basic anion exchange resin (resin column diameter height ratio 1: 10, resin consumption is 3 times of earthworm). First elute with 9 times the column volume of deionized water until th...

Embodiment 3

[0031] Example 3 Preparation of acid fraction of earthworm

[0032] Preparation:

[0033] Take 1000g of dried Earthworm, crush it into coarse powder, add 2 times the amount of Earthworm to soak at room temperature for 2 hours, filter; add 2 times the amount of Earthworm to soak at 40°C for 1 hour, filter, repeat this operation once, Filter, combine the filtrates three times, centrifuge at low speed for 3min, take the centrifuged supernatant, concentrate under reduced pressure to 2 times the volume of earthworm, then add 95% ethanol to make the alcohol content reach 70%, let stand for 8h, centrifuge, take the supernatant liquid, the supernatant was concentrated under reduced pressure to 2 times the volume of the earthworm dosage. Pass it through strongly basic anion exchange resin (resin column diameter height ratio 1: 10, resin consumption is 2 times of earthworm). First elute with 3 times the column volume of deionized water until the eluate is neutral and colorless, then elu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com