Electrostatic composition based on a polyamide matrix

A composition, polyamide technology, used in polyamide coatings, coatings, transportation and packaging, etc., can solve the problems of increasing the viscosity of thermoplastic matrix, negative effects on plastic properties, etc., to achieve good heat resistance, good surface appearance, good The effect of moldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

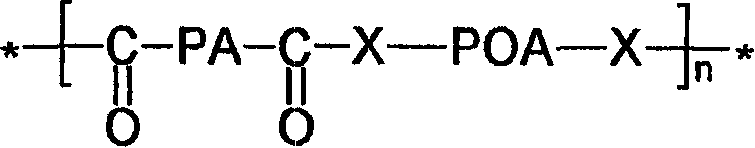

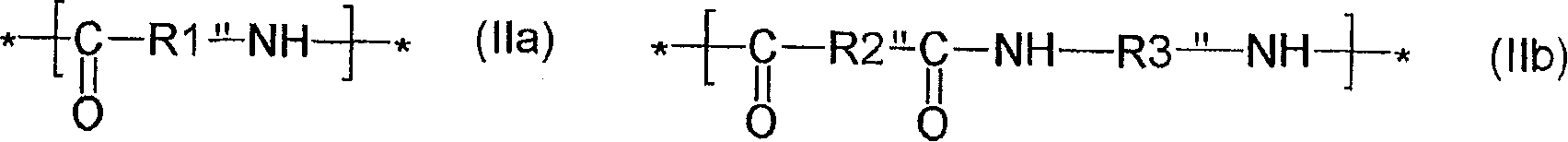

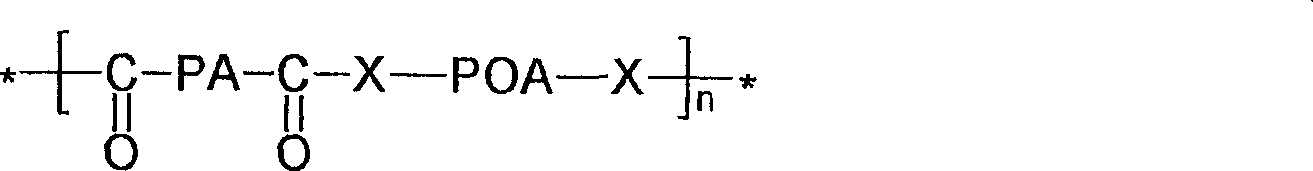

Method used

Image

Examples

Embodiment 1

[0096] Embodiment 1: the preparation of composition

[0097] Using a twin-screw extruder, polyamide-based compositions were prepared by mixing the different compounds described below. In Table 1 the composition, the compounds used and their amounts are given.

[0098] formula

A

B

C

D

E

F

G

1

2

PA66(%)

54.5

56.5

58.5

59.8

60.5

55.5

50.5

58.5

57.5

PA6(%)

10

10

10

10

0

0

0

0

0

Elastomer (%)

12

12

12

12

12

12

12

12

12

Mica (%)

15

15

15

15

15

15

15

15

15

Other (%)

2.5

2.5

2.5

2.5

2.5

2.5

2.5

2....

Embodiment 2

[0111] Embodiment 2: the preparation of composition

[0112] Using a twin-screw extruder, polyamide-based compositions were prepared by mixing the different compounds described below. In Table 2 the composition, the compounds used and their amounts are given.

[0113] formula

[0114] paint adhesion

[0115] The percentages of the various components are expressed as weight percentages relative to the total weight of the composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com