Guide wire

A technology for guide wires and guide wire parts, applied in catheters, guide wires, surgery, etc., can solve problems such as inability to improve the bonding strength of guide wire parts, difficulty in obtaining torque transmission, troublesome connection operations of guide wire parts, etc., and achieve excellent Operability, avoiding stress concentration on welded parts, preventing sudden bending (bending) or twisting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

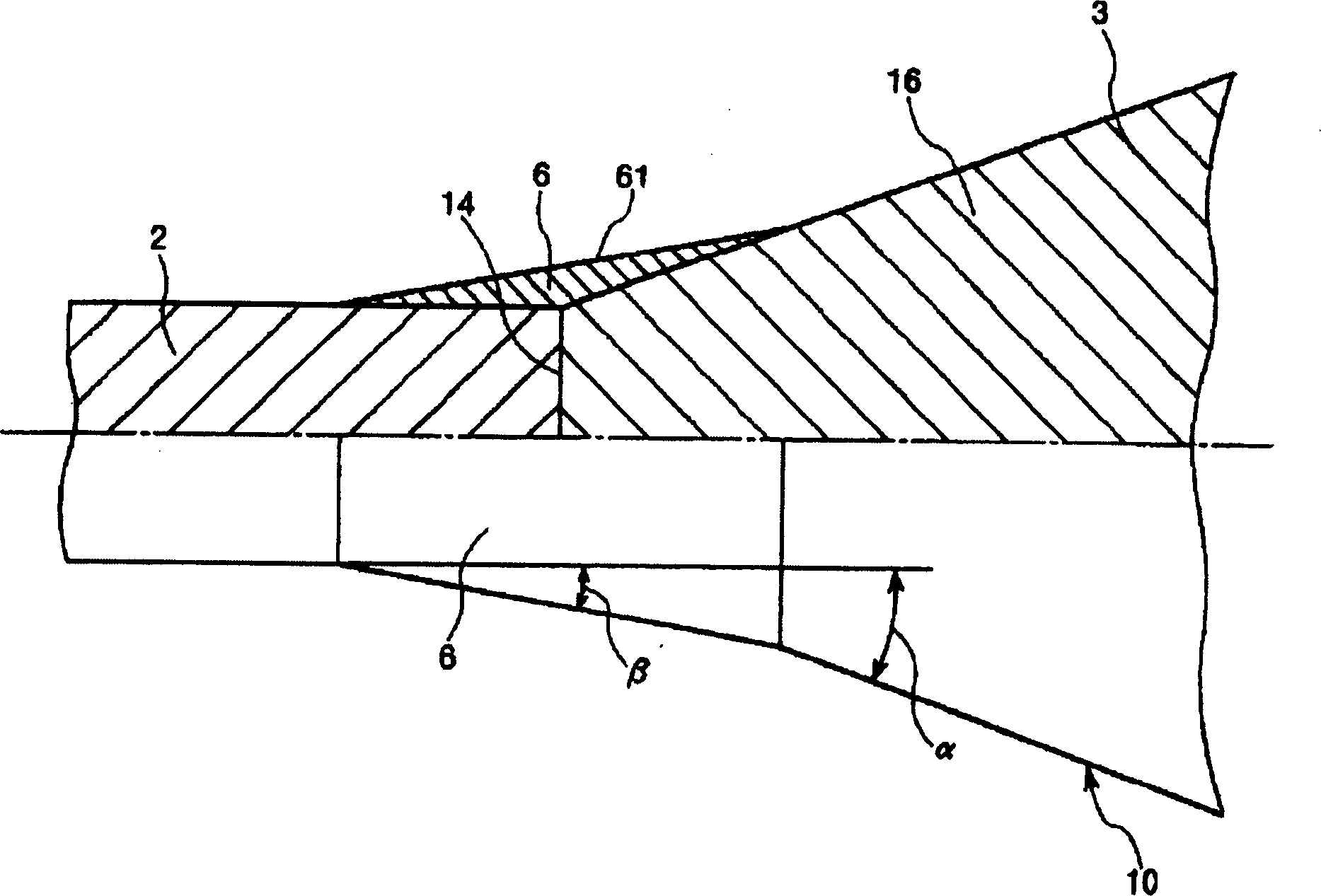

[0075] The guide wire of the present invention will be described in detail below according to the preferred embodiments shown in the accompanying drawings.

[0076] figure 1 is a longitudinal sectional view showing an embodiment of the guide wire of the present invention; figure 2 It is an enlarged longitudinal sectional view showing the vicinity of the joint portion of the guidewire main body in the guidewire of the present invention. Moreover, for the convenience of illustration, figure 1 as well as figure 2 The right side is the "base end" and the left side is the "front end". In addition, in figure 1 as well as figure 2 In , the length in the longitudinal direction of the guide wire is shortened for easy understanding, and the dimension in the thickness direction of the guide wire is shown in an exaggerated manner, and the ratio of the dimension in the longitudinal direction to the dimension in the thickness direction is different from the actual situation.

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com