Absorbent resin particle, and absorber and absorbent article employing the same

A technology of resin particles and absorbency, which is applied in absorbent pads, medical science, bandages, etc. It can solve the problems of reduced absorption capacity and absorption speed, easy leakage, etc., and achieves excellent balance, dry touch feeling, and excellent absorption time. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

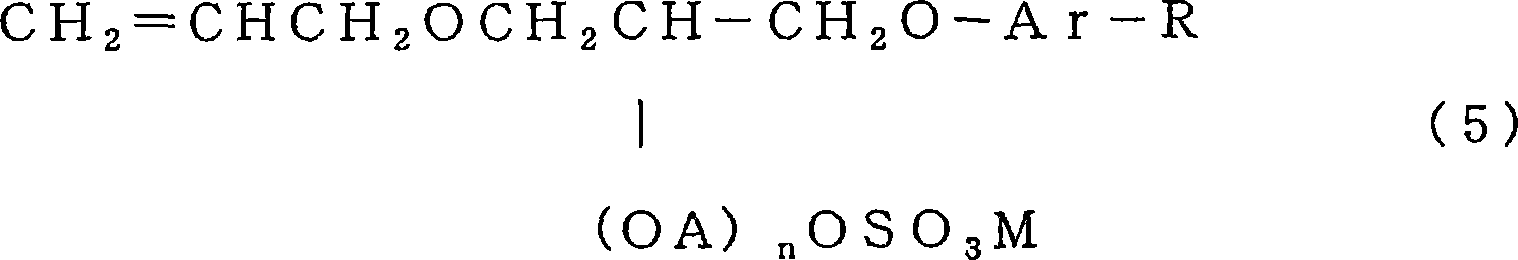

[0320] Add 40 parts of material (DD11) and 0.4 parts of diffusion penetrant (E1) ("SANMORIN OT 70" manufactured by Sanyo Chemicals Co., Ltd., anionic surfactant) to 400 parts of hydrogel-like polymer (AA-1), Knead at 25° C. for 5 minutes using a shredder (hole diameter of a porous plate: 6 mm, manufactured by Iizuka Industrial Co., Ltd., “12VR-400K”), and then use a ventilated belt dryer at 135° C. at a wind speed of 2.0 m / sec. Drying is carried out under certain conditions to obtain a dried polymer.

[0321] Use a commercially available fruit juice extractor to pulverize the dried polymer, adjust the particle size to 25 μm to 600 μm using sieves with sieve openings of 600 μm and 250 μm, and then stir at a high speed (a high-speed stirring turbulence enhancer manufactured by Hosokawa Micron Co.: 2000 rpm ) 100 parts of the granules, spray and add 2 parts of ethylene glycol diglycidyl ether 10% water / methanol mixed solution (weight ratio of water / methanol=70 / 30) and mix, stand ...

Embodiment 2

[0323] Absorbent resin particles (2) were obtained in the same manner as in Example 1 except that material (DD12) was used instead of material (DD11).

Embodiment 3

[0325] Absorbent resin particles (3) were obtained in the same manner as in Example 1 except that material (DD13) was used instead of material (DD11).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com