Color image forming apparatus

A color image and image technology, applied in the field of color image forming devices, can solve the problems of complex structure of processing system, difficulty in obtaining full-color images, difficulty and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

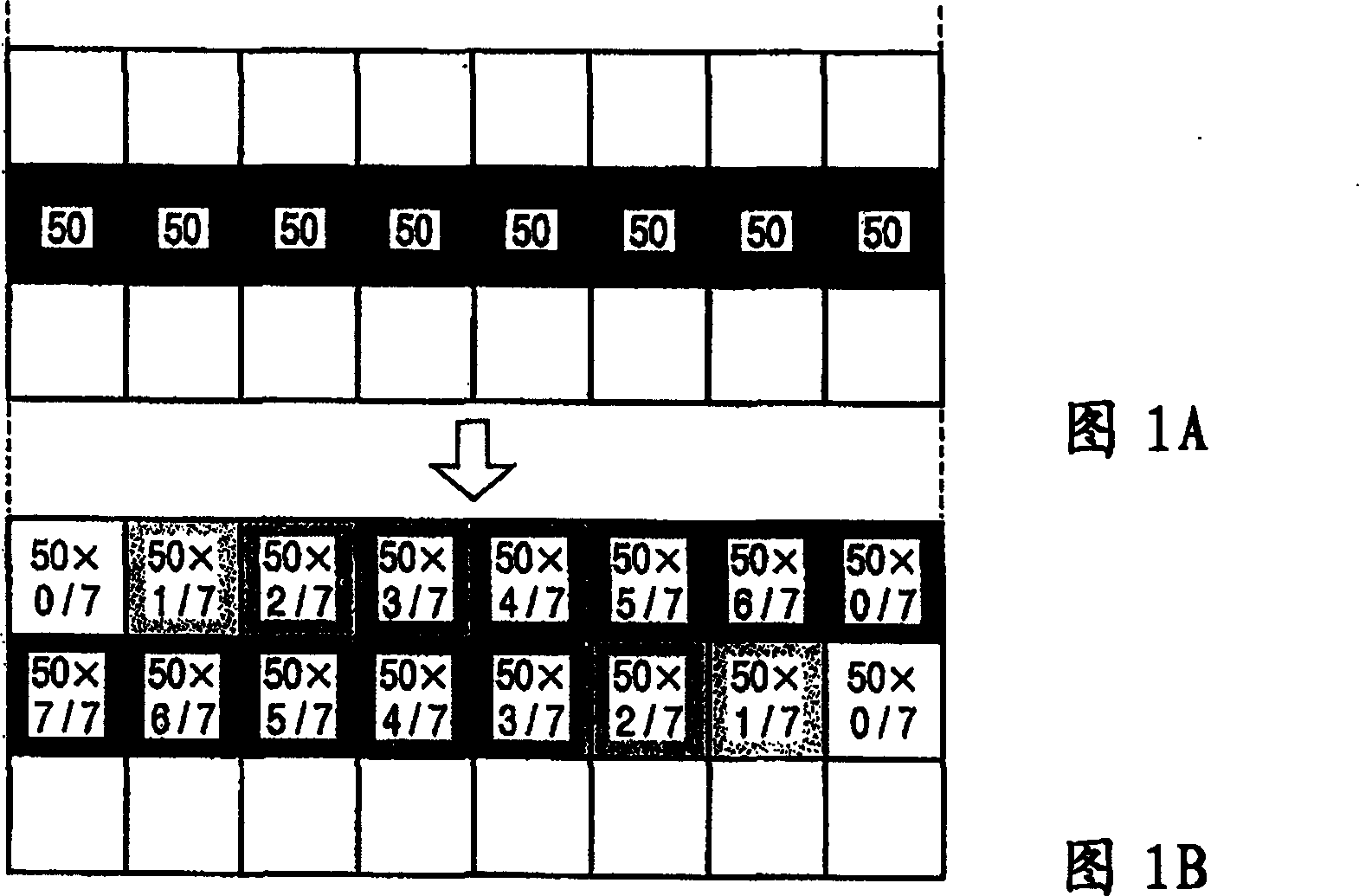

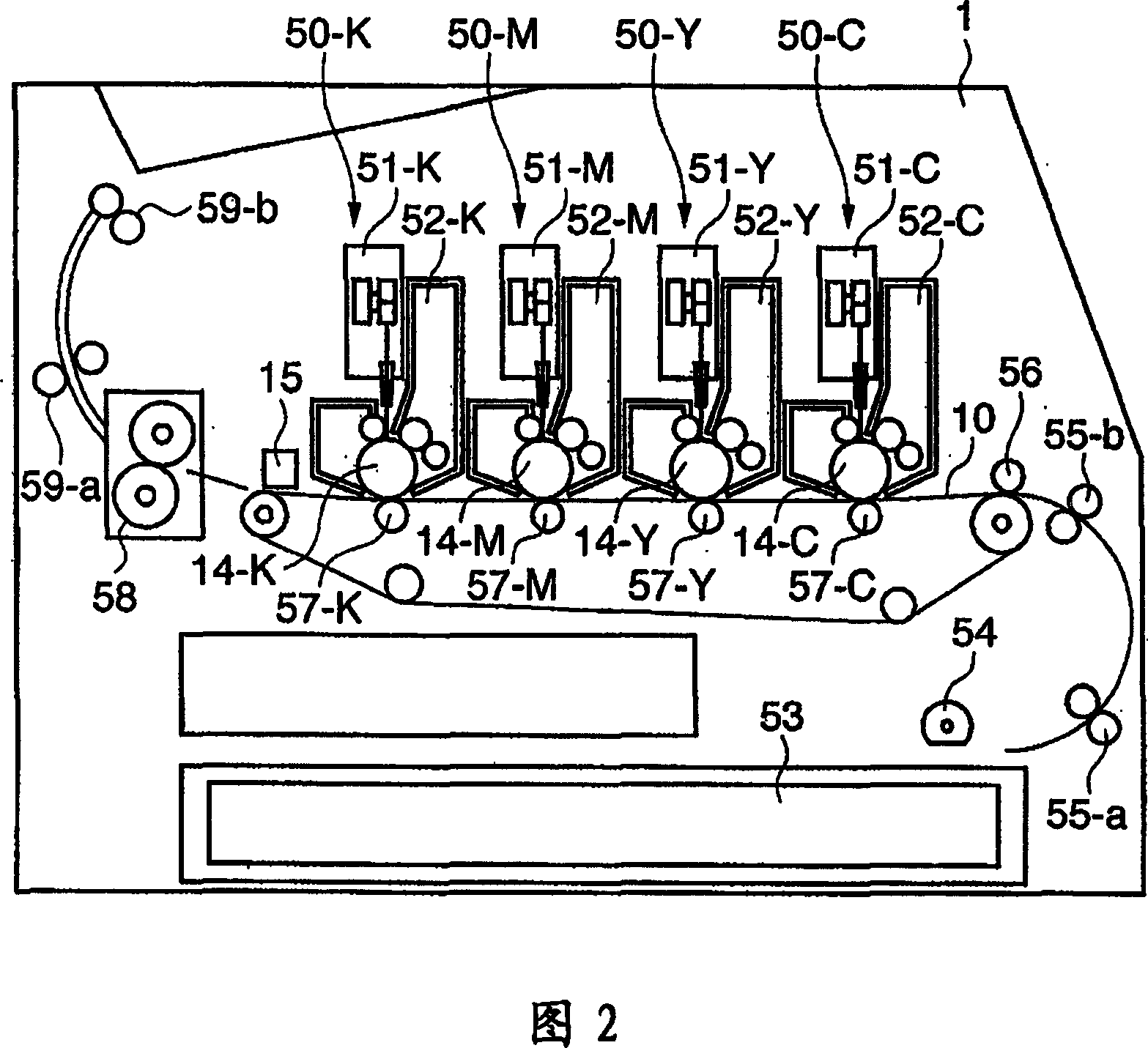

[0058] figure 2 It is a schematic cross-sectional view showing the configuration of the color image forming apparatus in this embodiment. The illustrated color image forming apparatus 1 is, for example, a so-called tandem color laser printer having four photosensitive drums. In this color image forming apparatus 1 , a transfer material cartridge 53 is attached to the lower part of the right side of the main unit. The transfer materials placed in the transfer material cassette 53 are taken out one by one by the paper feed roller 54, and sent to the image forming section by the pair of conveying rollers 55-a, 55-b. In the image forming section, the transfer conveyor belt 10 that conveys the transfer material is driven by a plurality of rotating rollers along the transfer material conveying direction ( figure 2 The transfer material is electrostatically adsorbed on the transfer conveyor belt 10 at its most upstream portion.

[0059] In the color image forming apparatus 1 , f...

no. 2 Embodiment approach

[0138] In the second embodiment, for example, when switching the density of gradation correction with 3 pixels and 4 levels, at (a) the position where the coordinate transformation is performed, (b) the position one pixel before the position where the coordinate transformation is performed, ( c) The above-mentioned switching is performed at a position 2 pixels before the position where the coordinate transformation is performed.

[0139] Therefore, the color misregistration position calculation units 407C, 407M, 407Y, and 407K calculate the position one pixel before the position where the coordinate transformation is performed and the position two pixels before the position where the coordinate conversion is performed, respectively.

[0140] FIG. 9 is a diagram explaining the color misregistration correction performed by the gray scale correction unit 804 which is smaller than the pixel unit. By adjusting the exposure ratios of dots before and after the sub-scanning direction,...

no. 3 Embodiment approach

[0177] According to the above-mentioned Patent Document 2 (Japanese Patent Laid-Open No. 8-85237 ), the coordinate positions of image data for outputting each color are corrected for an image subjected to halftone processing. For this reason, when dithering is performed, the halftone dot reproducibility of the halftone image deteriorates. As a result, color unevenness may occur, and moiré may become conspicuous. Furthermore, when such non-uniform density values are periodically repeated, there is a problem that moiré is conspicuous and a good color image cannot be obtained. The third embodiment solves such a problem.

[0178] The color image forming apparatus according to the embodiment of the present invention is also a 4-drum color laser printer, citing figure 2 .

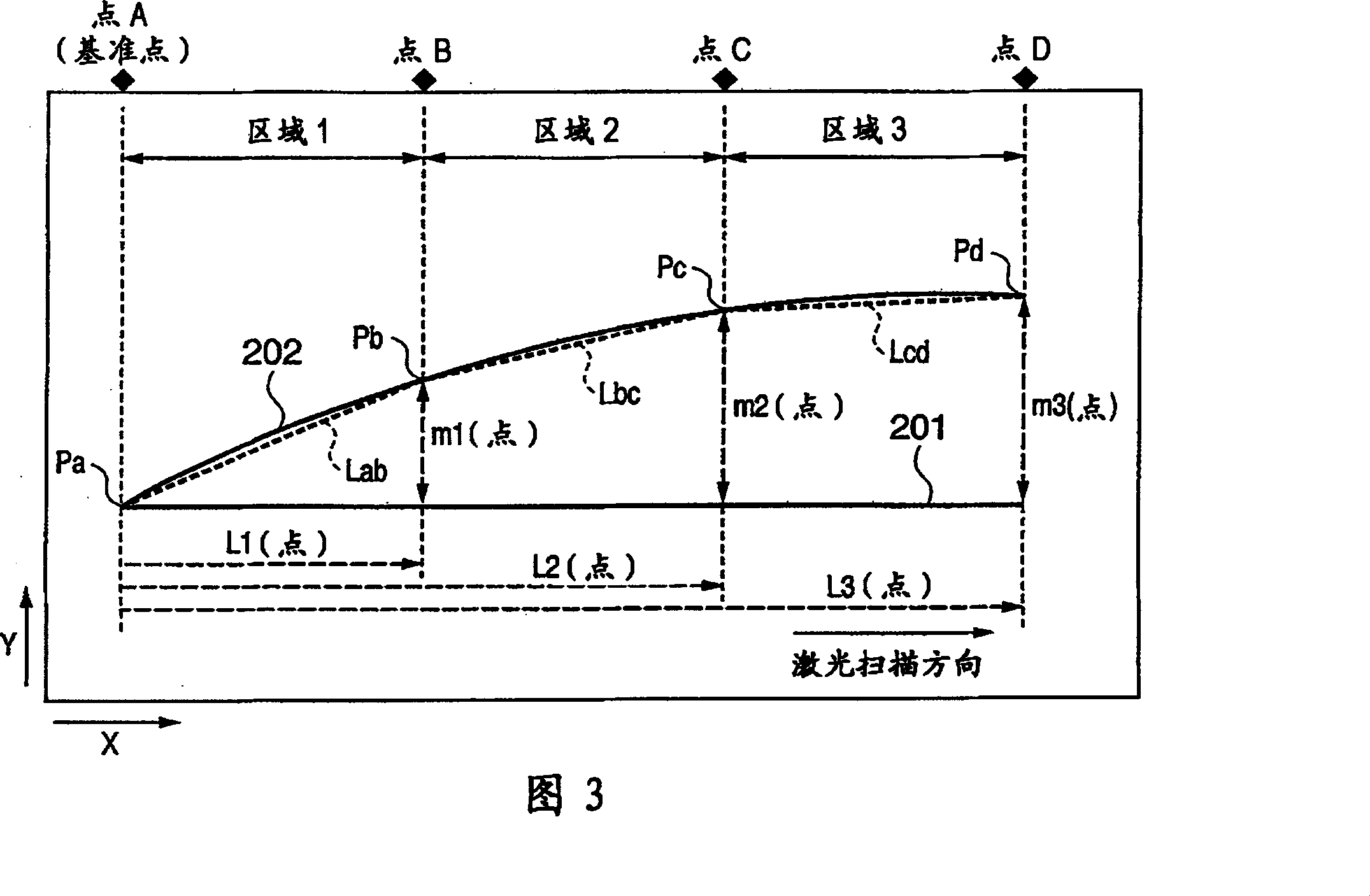

[0179] Figure 10 It is a conceptual diagram explaining the variation of the main scanning line scanned on each photosensitive drum 14 (for example, the photosensitive drum 14-C for cyan) serving as an ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com