Dual-axis capacitance type micromechanical accelerometer

A technology of capacitive micromachines and accelerometers, applied in the direction of measuring acceleration, speed/acceleration/shock measurement, measuring devices, etc., can solve the problems of insufficient sensitivity and resolution, achieve improved sensitivity, high resolution, and realize overload protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

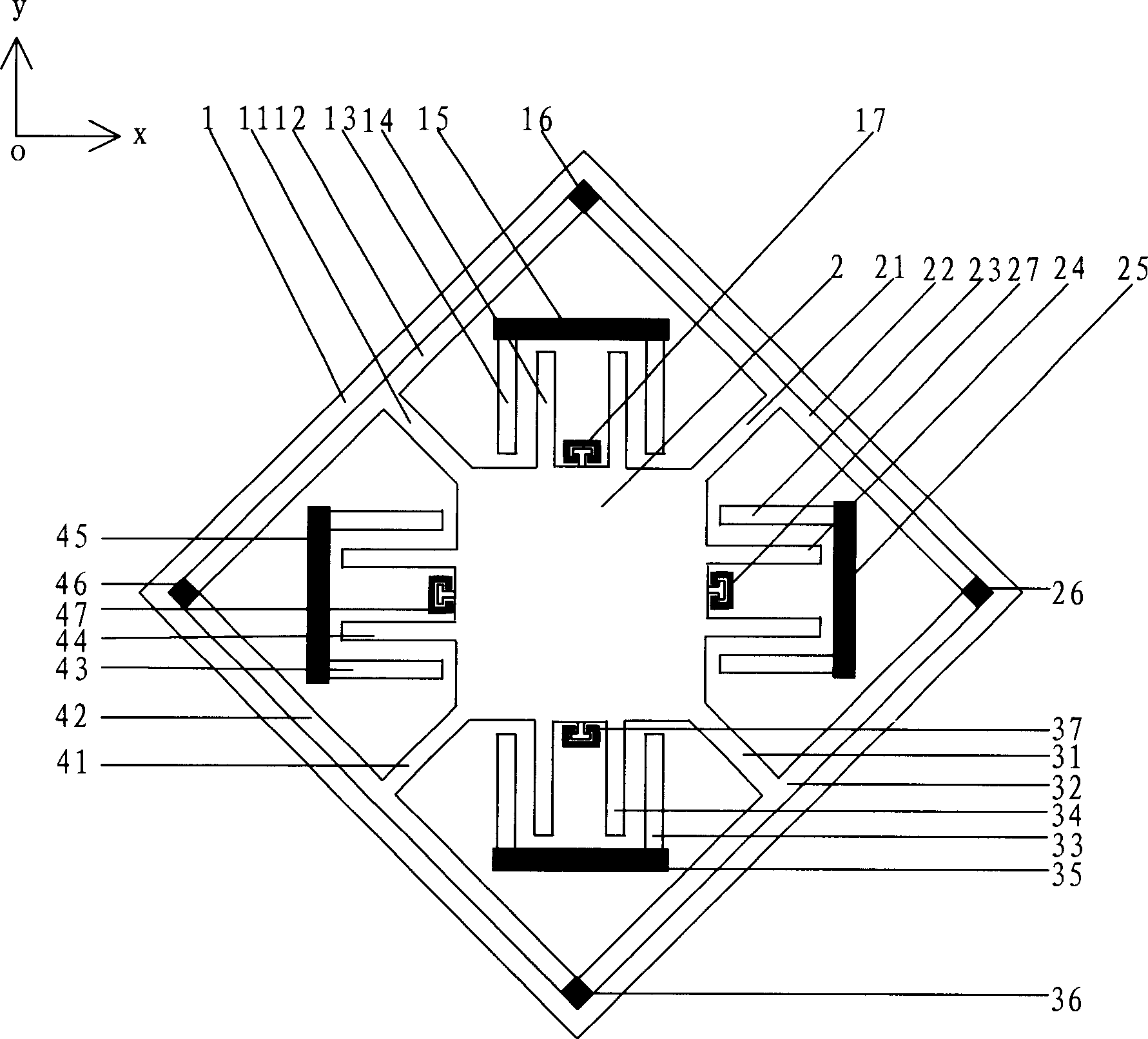

[0008] Such as figure 1 As shown, the present invention includes substrate 1, mass block 2, elastic support, drive electrode and detection electrode, tooth hub 15, 25, 35, 45, tooth hub 15, 25, 35, 45, stopper 17, 27, 37 , 47. The anchor points 16, 26, 36, 46 are connected to the substrate 1 through bonding, the structure is center-symmetrical, and a mass 2 is used to sense accelerations in two orthogonal directions. The mass block 2 is located in the center of the structure, and the periphery of the mass block 2 is elastic support, stoppers 17, 27, 37, 47, tooth hubs 15, 25, 35, 45, drive electrodes and detection electrodes. The elastic support is composed of four double-ended fixed beams 12, 22, 32, 42 and four cantilever beams 11, 21, 31, 41, and the four double-ended fixed beams 12, 22, 32, 42 form a square. The four corners are anchor points 16,26,36,46. One end of each cantilever beam 11 , 21 , 31 , 41 is fixedly connected to the mass block 2 , and the other end is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com