Enclosed lubrication mechanism for bearing of wet-type abrasive band grinding machine and enclosed lubrication method

A belt grinding and lubricating structure technology, which is applied in the direction of abrasive belt grinders, bearing components, shafts and bearings, etc., can solve the problems of bearing heating, mixing, burning, etc., and achieve the effect of improving service life and precision and ensuring lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

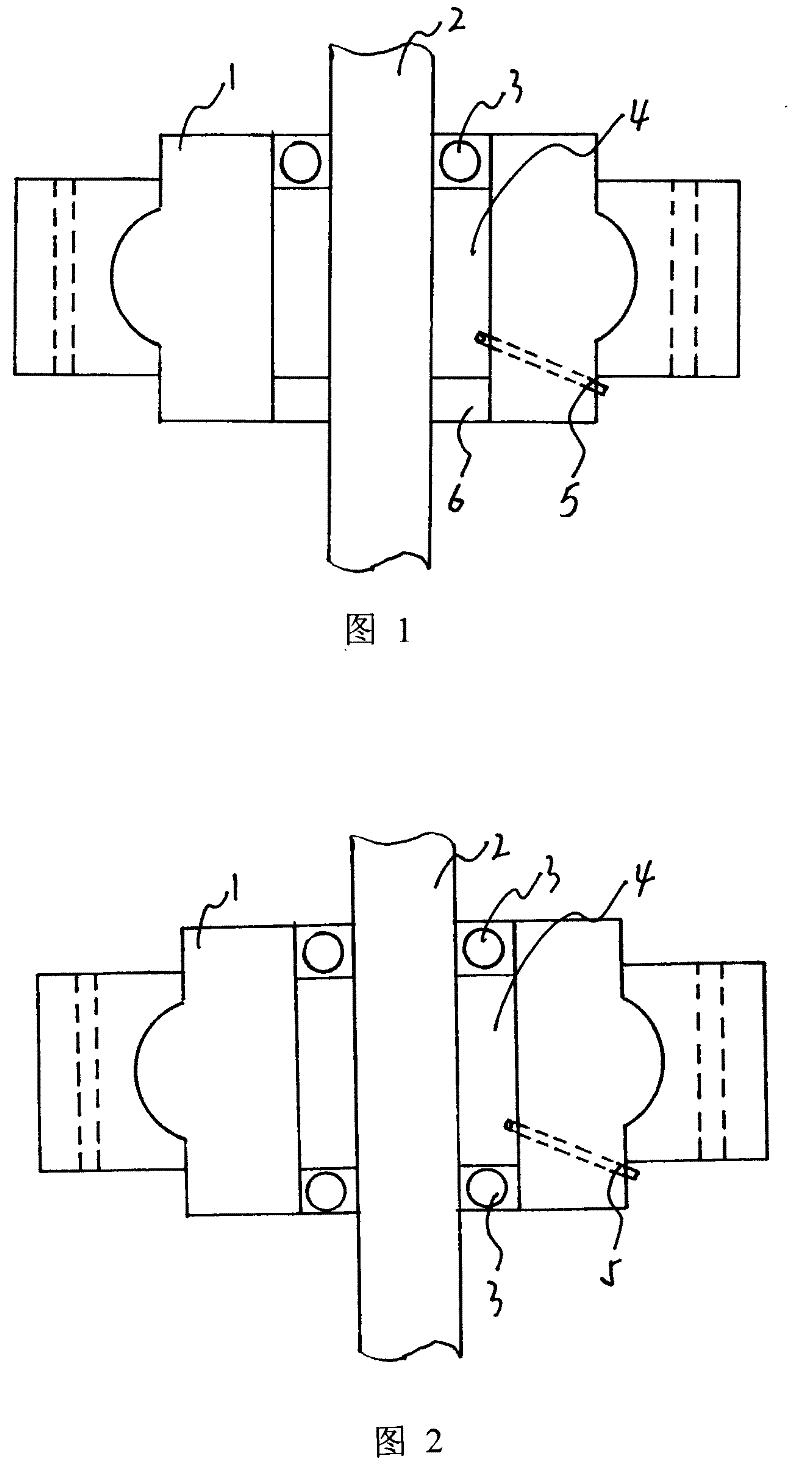

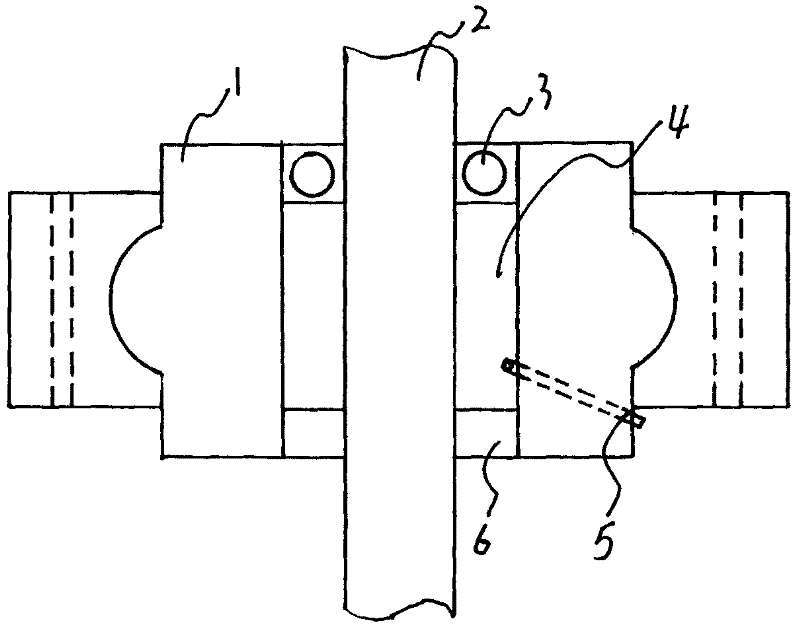

[0016] Embodiment 1: with reference to attached figure 1 . The main shaft bearing sealing and lubricating structure of the wet abrasive belt grinder includes a main shaft 2 and a bearing seat 1. The processing of the main shaft and the bearing seat (aligning or non-aligning) is a prior art, and will not be described here. The cavity formed by the bearing 3 and the sealing ring 6 in the bearing seat 1 or between the two bearings 3 is an oil chamber 4 and an oil inlet channel 5 is opened on the wall of the oil chamber, that is to say, the cavity where the bearing is installed in the bearing seat Bearing 3 and sealing ring 6 are installed at both ends respectively, and the cavity (cavity) formed between bearing 3 and sealing ring 6 is the oil cavity 4 mentioned in the present invention, or the two ends of the cavity where the bearing seat is installed with bearing are installed respectively. Bearing 3 is arranged (bearing 3 replaces sealing ring 6 and bearing 3 is a single-sided...

Embodiment 2

[0017] Embodiment 2: On the basis of Embodiment 1, the method of sealing and lubricating the main shaft bearing of the wet abrasive belt grinder, the oil (lubricating oil) located in the oil chamber in the bearing seat is in the process of the main shaft driving the bearing to rotate at a high speed, and the oil located in the bearing The oil is heated by the heat generated by the high-speed rotation of the bearing to generate a small amount of oil vapor, which forms a positive pressure in the oil chamber and forces the grease in the oil chamber to supply oil to the bearing and to the sealing ring in contact with the spindle. The oil pressure is applied positively to the inner surface or the bearing sealing ring surface to prevent external impurities from invading the bearing and sealing ring, and the oil is continuously replenished into the oil chamber through the oil inlet passage.

Embodiment 3

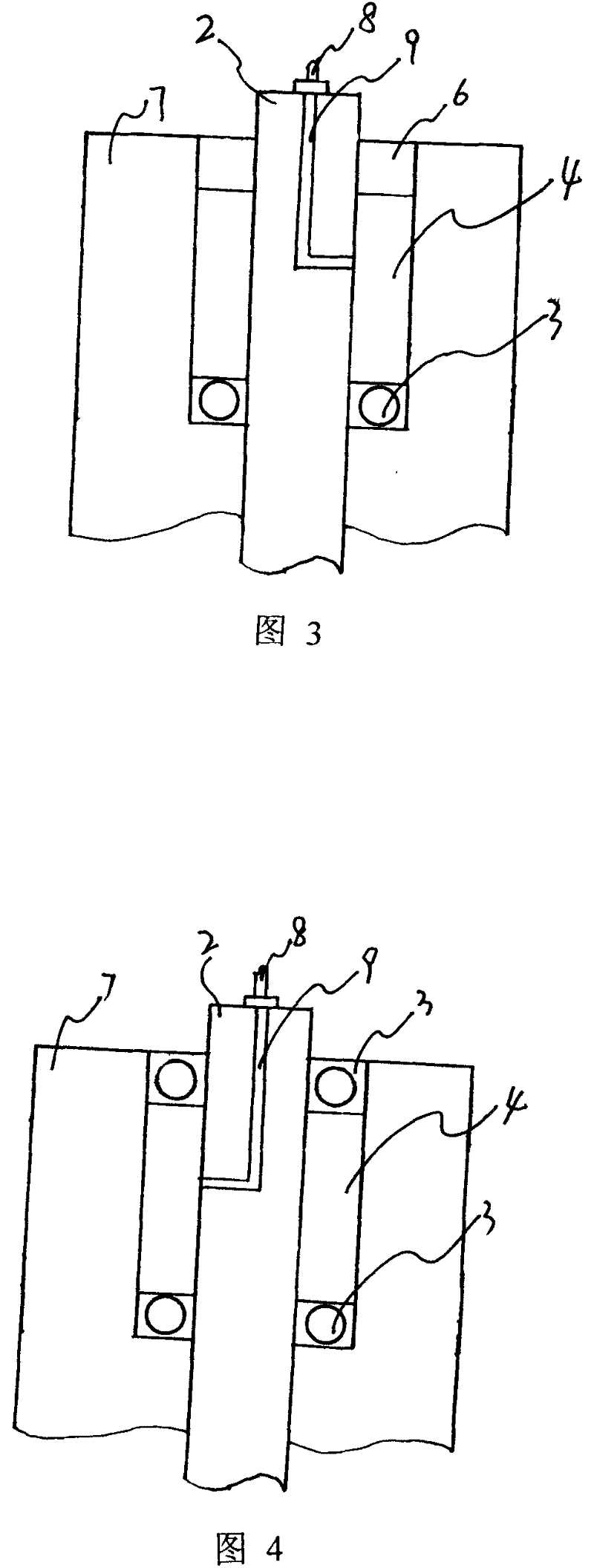

[0018] Embodiment 3: with reference to attached figure 2 . Wet abrasive belt grinding motorized roller bearing seal lubrication structure, it comprises main shaft 2 and moving roller 7, the processing and making of main shaft 2 and moving roller 7 are prior art, do not narrate here. The central recess at the end of the moving roller is the bearing seat, the cavity formed by the bearing 3 and the sealing ring 6 or the two bearings 3 in the bearing seat is the oil chamber 4, and the main shaft 2 has an oil inlet channel 9 in the axial direction and is connected with The oil chamber 4 in the bearing seat communicates. That is to say, the two ends of the cavity where the bearing is installed in the bearing seat are respectively equipped with a bearing 3 and a sealing ring 6, and the cavity (cavity) between the bearing 3 and the sealing ring 6 is the oil cavity 4 in the present invention, or the bearing Bearings 3 are installed at both ends of the cavity where the bearing is mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com