Feeding distributor with anti-eddy flow baffle plate

A feed distributor and distributor technology, applied in distillation separation, separation method, dispersed particle separation, etc., can solve the problems of large gas flow pressure drop, uneven distribution, and it is difficult for the distributor to achieve uniform distribution of materials, etc. Achieve the effect of eliminating airflow rotation and avoiding unevenness of gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

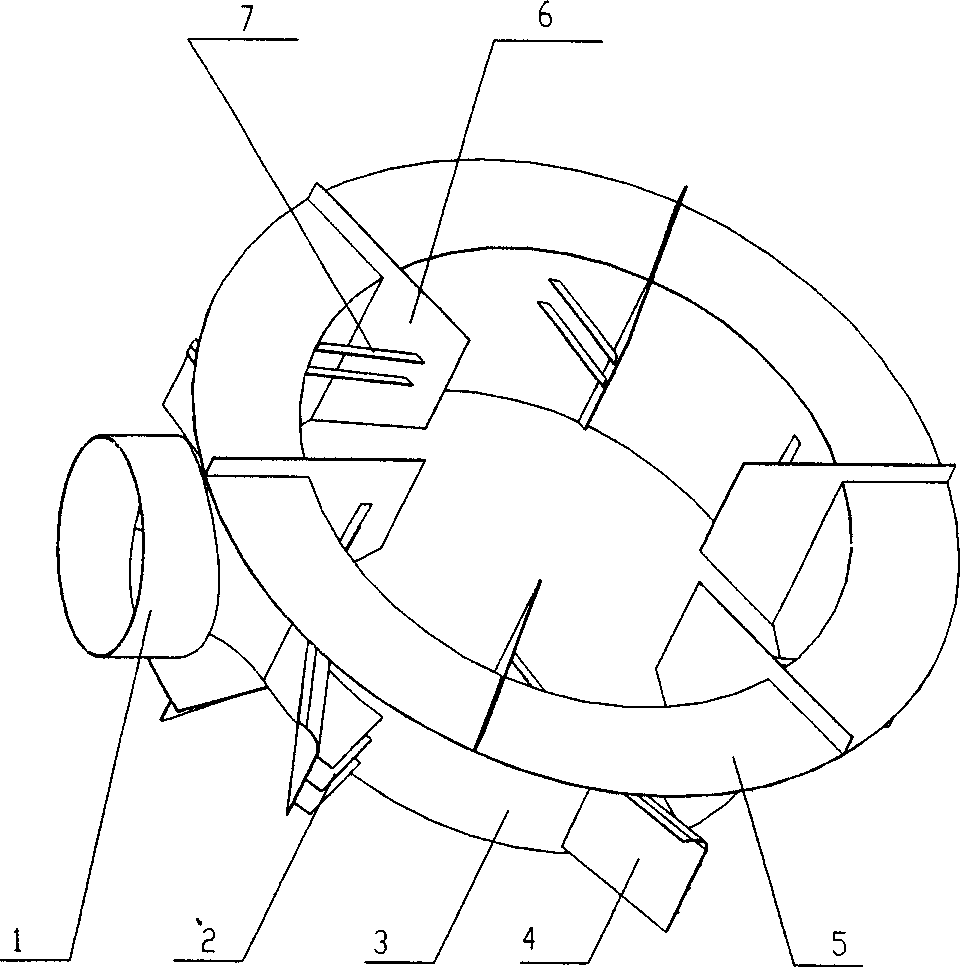

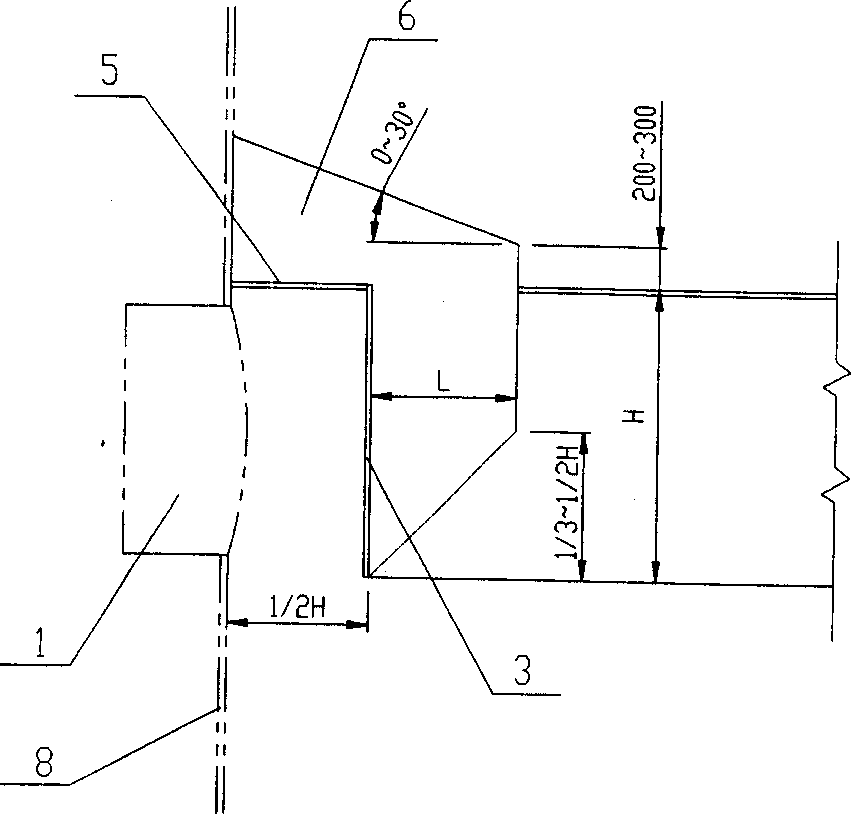

[0016] The double tangential feed distributor with anti-swirl baffles of the present invention has a basic structure including an inner sleeve, a cover plate, a deflector 4, reinforcement ribs of the deflector, an anti-swirl baffle, and tie bars. The cover plate and the tower wall form an annular space with a closed top and an open bottom. The deflector is arranged between the tower wall and the inner sleeve, and the two sides are respectively fixed on the tower wall and the inner sleeve and provided with deflector ribs In order to improve the strength, the height of the deflector changes gradually from the feed inlet along the annular channels on both sides. The anti-swirl flow baffle is arranged on the inner side of the inner sleeve, and the side is provided with tie bars, and the other end of the tie bars is fixed on the inner sleeve.

[0017] like figure 1 The shown cover plate 5 is ring-shaped, located on the top of the inner sleeve 3 , one end is fixed on the tower wall...

Embodiment 2

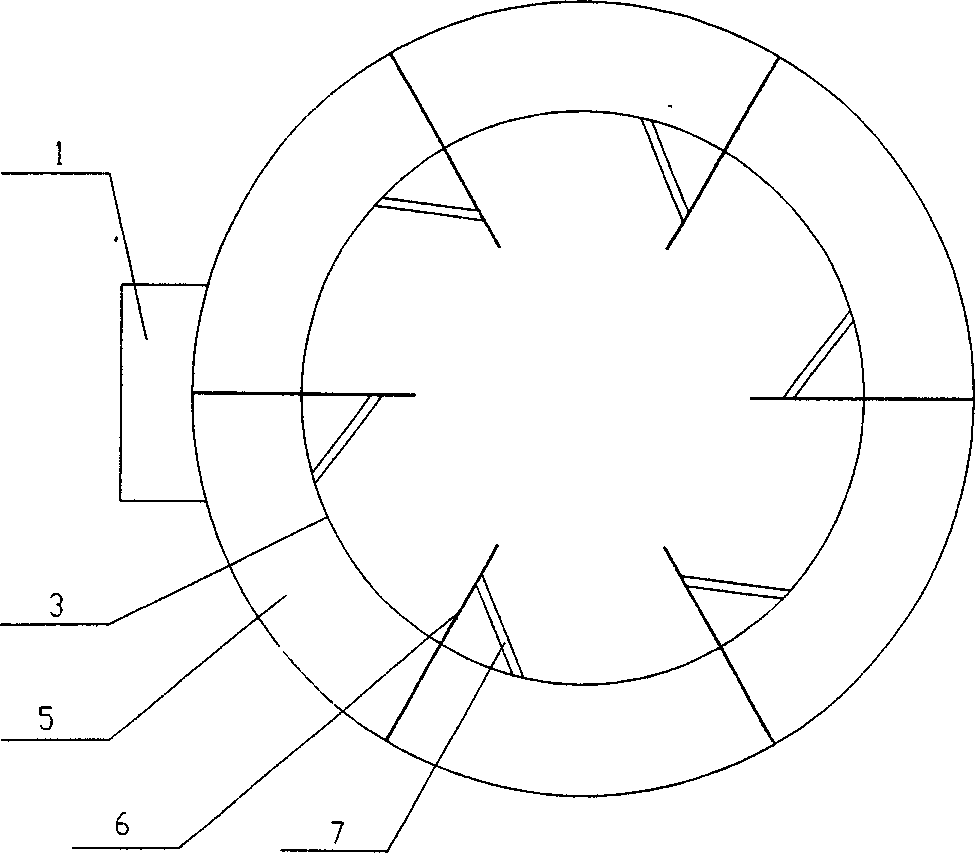

[0023] The basic structure of the single tangential feed distributor with an anti-swirl baffle is the same as that of the double tangential feed distributor with an anti-swirl baffle described in Example 1. The setting of the cover plate 5 and the height setting of the inner sleeve 3 are the same as in Embodiment 1, the structure and shape of the anti-swirl flow baffle 6, the dimensional relationship between the baffle and the inner sleeve, the setting of the number of baffles, and the arrangement of the tie bars 7 The settings are the same as in Example 1.

[0024] like Figure 4 As shown, for a single tangential feed distributor, the width of the inner sleeve 3 is equal to the diameter of the feed port 1 or greater than the diameter of the feed port 1 by 20-200 mm; the anti-swirl flow baffle 6 is arranged inside the inner sleeve 3, Stretch ribs 7 are added on the side, and the size of each baffle gradually decreases along the direction of feed flow,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com