ITO thin film and method for producing same

A technology of ITO and thin film, applied in cable/conductor manufacturing, chemical instruments and methods, inorganic chemistry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

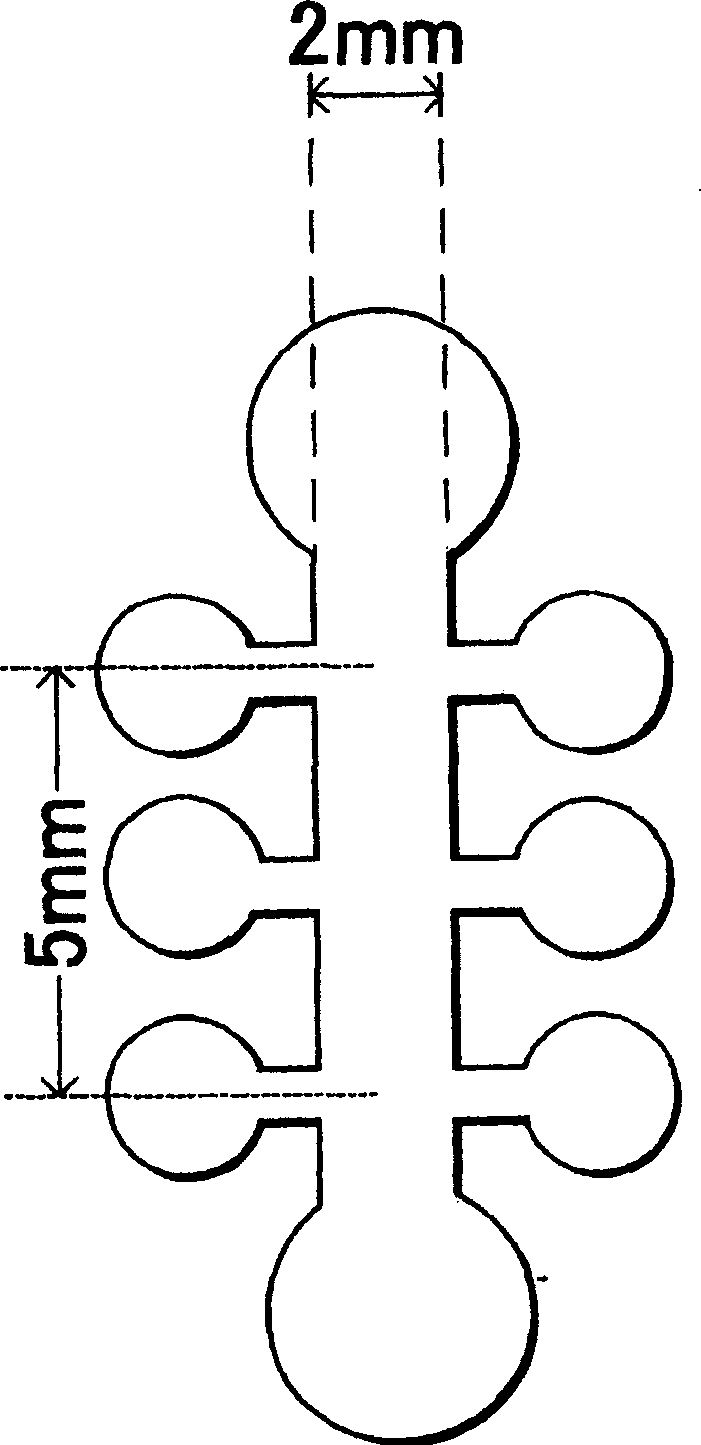

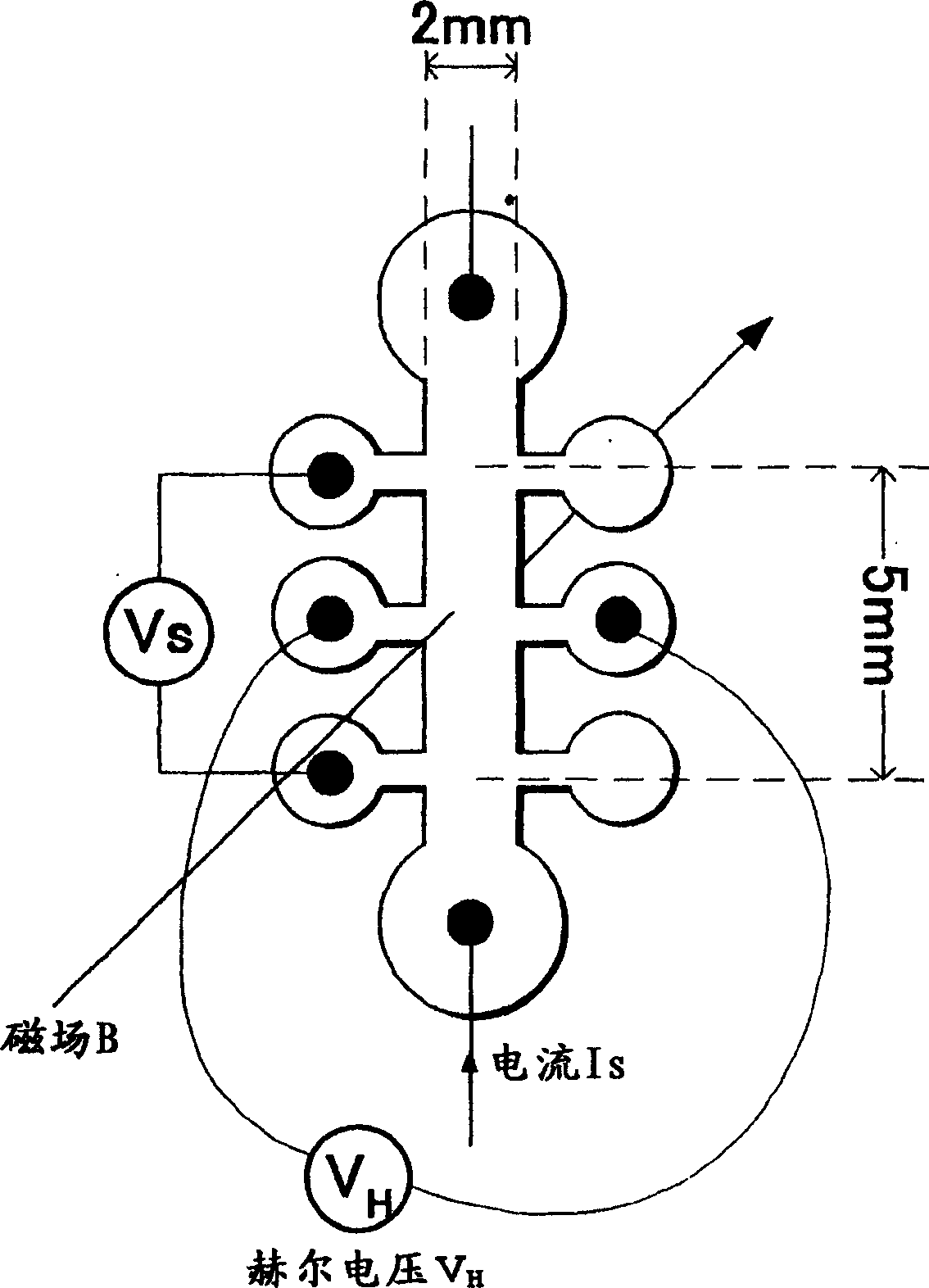

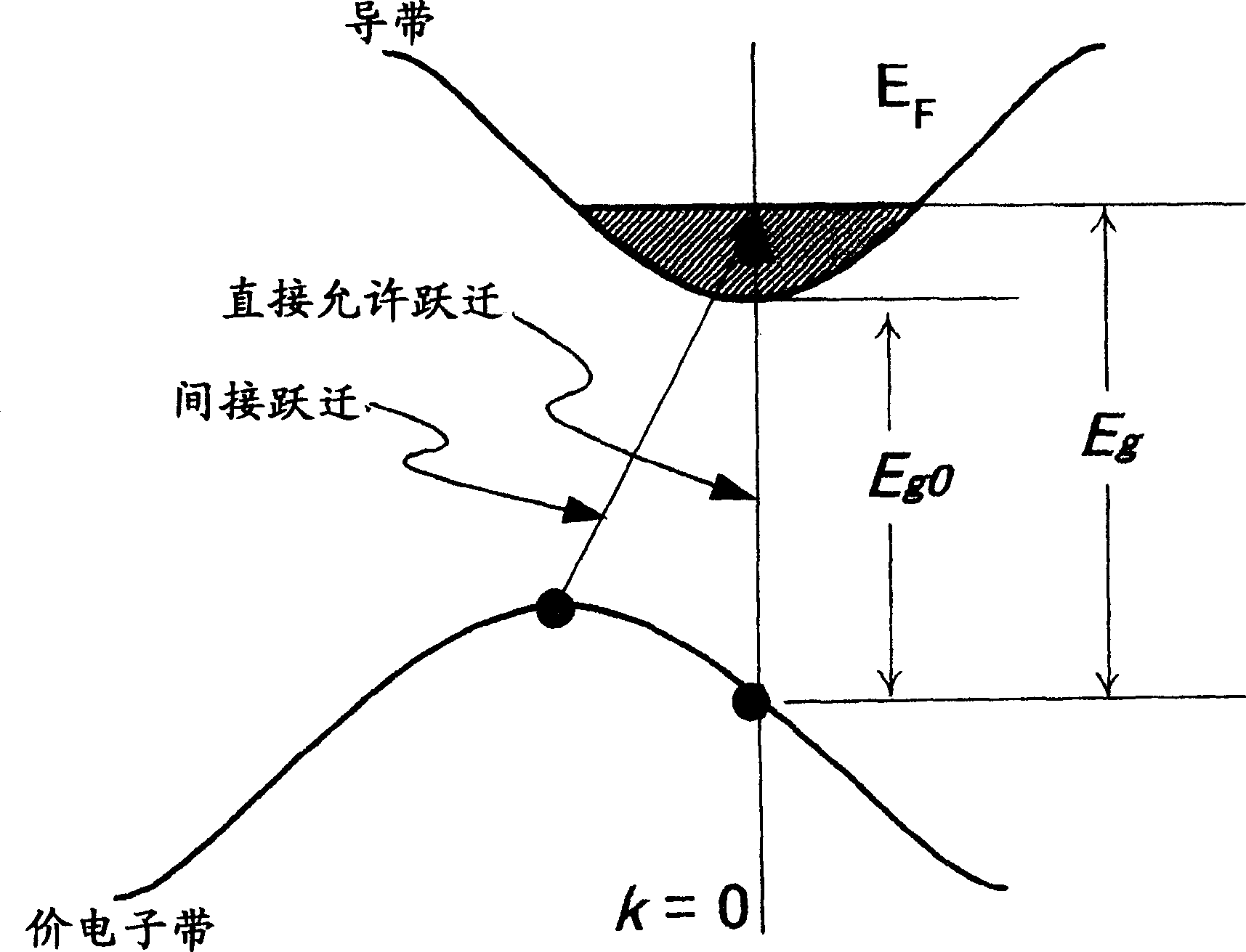

Image

Examples

Embodiment Construction

[0062] Preferred embodiments of the present invention will be described as follows:

[0063] First, a method for producing an ITO thin film by a spray method will be described below.

[0064] Relying on the spraying method in this example, the ITO thin film with a low tin concentration whose atomic percent concentration of tin is not higher than 4% is made of InCl 3 , SnCl 2 form a mixed solution with ethanol. In order to compare with the existing research results, ITO thin films with tin concentration as high as 4 to 14.6 atomic percent were also formed, and their characteristics were measured and analyzed.

[0065] As the spray solution in this example, indium chloride (InCl 3 3.5H 2 O, purity 99.99% manufactured by Wako Junyaku Corporation) and tin dichloride (SnCl 2 2H 2 O, purity 99.9% manufactured by Wako Junyaku) was dissolved and diluted in ethanol (purity 99.5% manufactured by Wako Junyaku), and the mixture was stirred with a magnetic rotor for 20 to 40 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com