Method for testing bursting strength of small-mesh fishing net

A test method and small mesh technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, strength characteristics, etc., can solve hidden dangers in fishery production, restrict the sustainable and healthy development of fishing and fishery engineering, and cannot detect small Mesh fishing net bursting strength and other issues, to achieve the effect of reasonable and reliable technical indicators, practical test methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

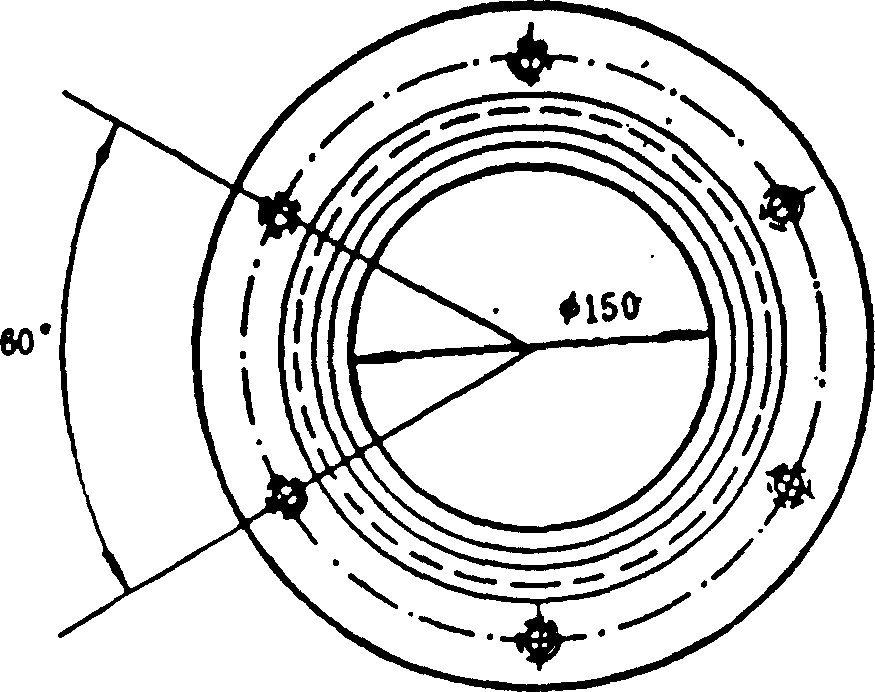

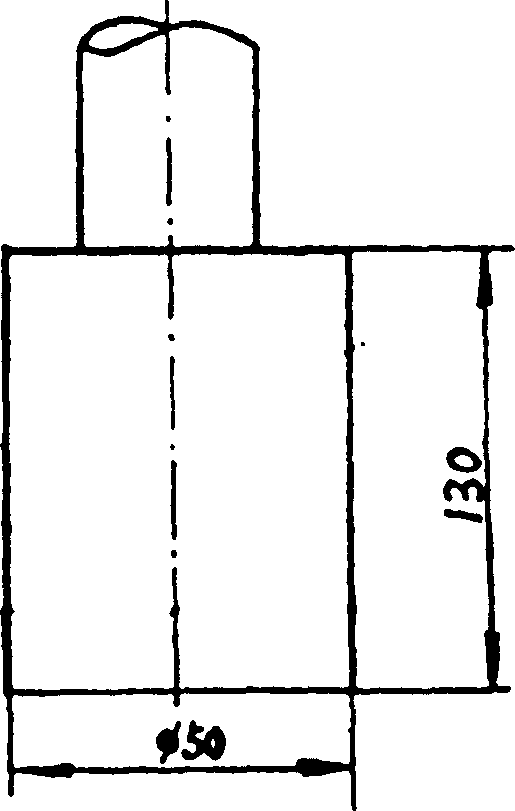

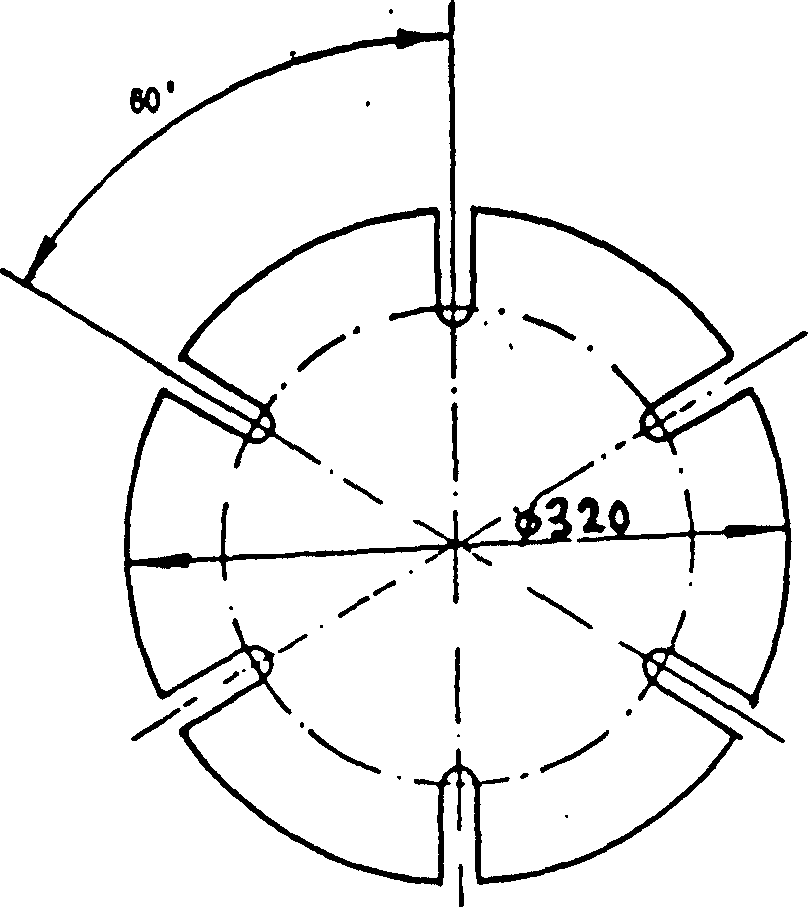

Image

Examples

Embodiment Construction

[0012] The factors that affect the results of the fishing net strength test include atmospheric conditions, test conditions, sampling and sample handling, test methods, data processing and result presentation. In order to prevent and avoid deviations and obtain accurate evaluation results, while explaining the specific test methods, the following describes the best ways to implement the present invention with respect to various factors affecting the expression of the fishing net strength test results:

[0013] The atmospheric conditions for the test are set according to the moisture absorption performance of the fishing net material. For fishing nets made of hygroscopic materials such as nylon fishing nets and vinylon fishing nets, the atmospheric conditions in the laboratory during the bursting strength test are (20±1)℃, Humidity (63~67)%, the balance time of the fishing net sample is more than 12h; fishing nets made of non-hygroscopic materials such as polyethylene fishing nets ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com