Decorative material for floor and its production method

A manufacturing method and technology of decorative materials, applied in the direction of building materials, manufacturing tools, wood processing equipment, etc., capable of solving problems such as immersion, damage resistance (impact resistance, insufficient resistance to inclination, corrosion, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

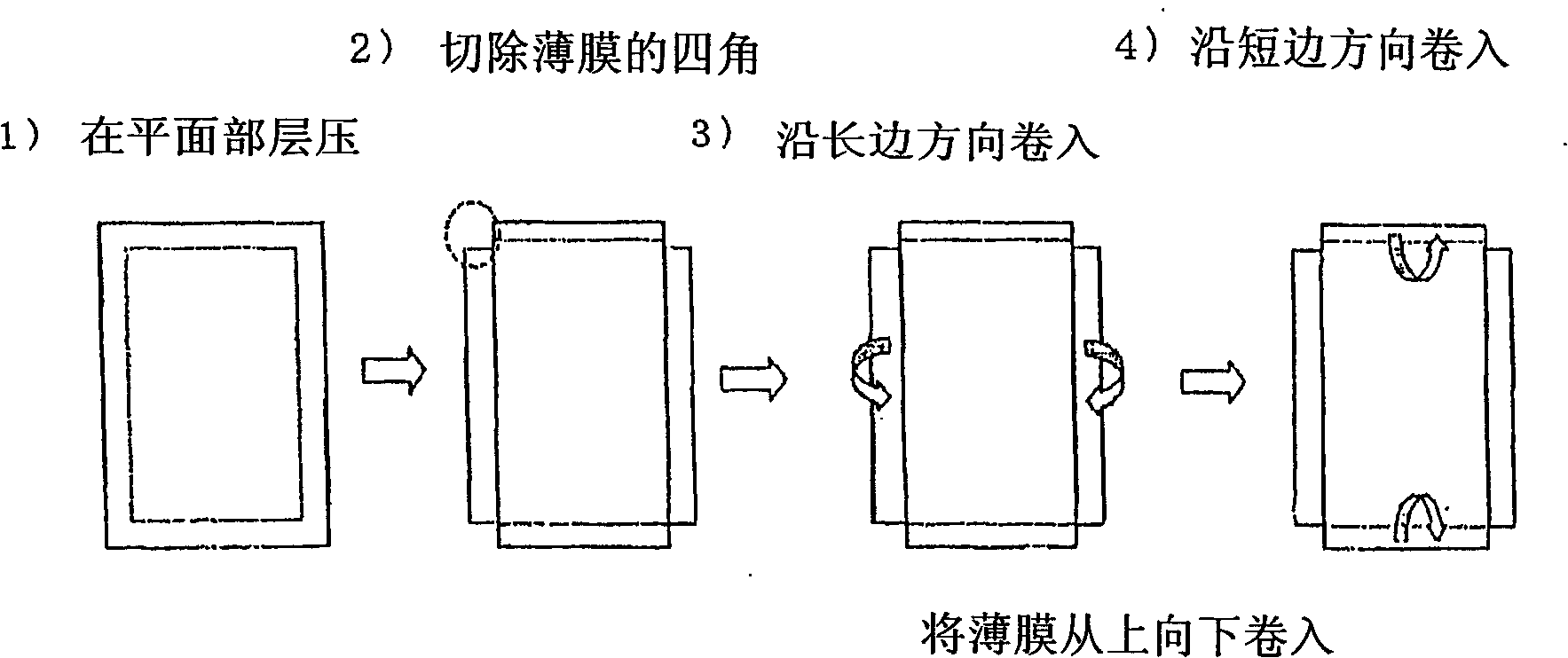

[0035] 1. Manufacturing method of decorative material for floor

[0036] The manufacturing method of the floor decoration material of the present invention comprises:

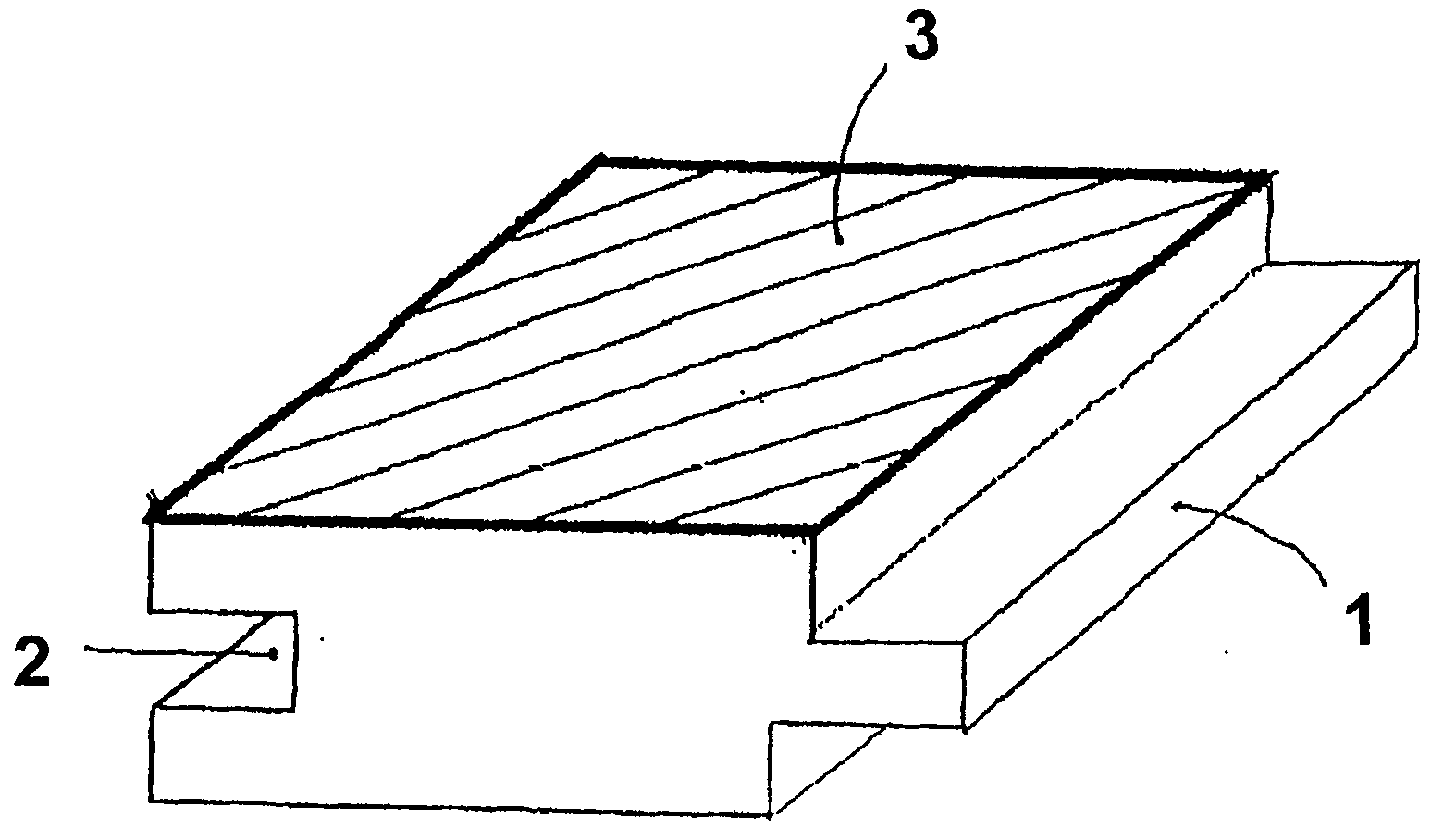

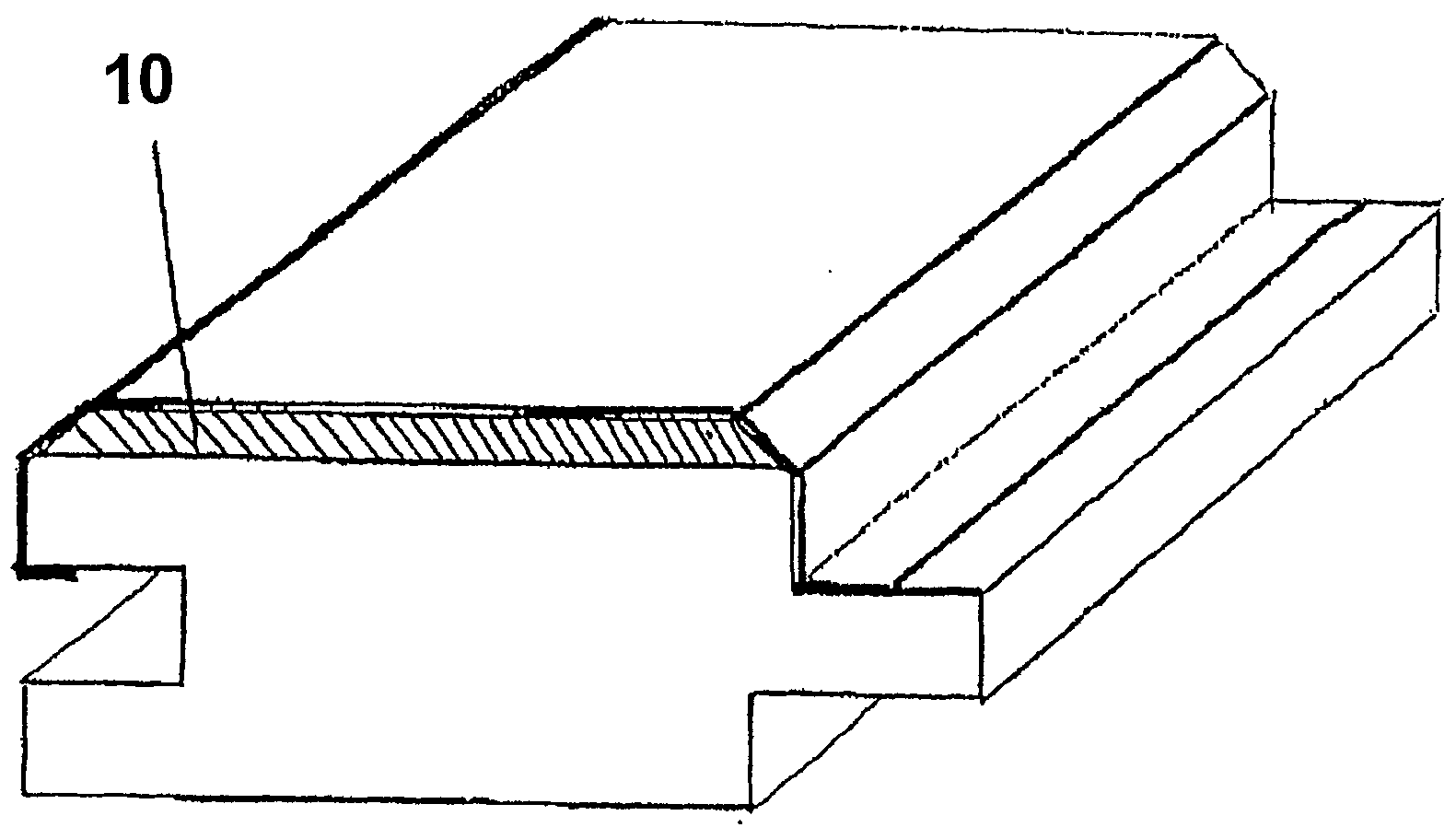

[0037] (1) The first step of forming a synthetic resin layer with a thickness of 100 μm or more on the plane portion of the wooden board;

[0038] (2) tongue and groove processing is performed on the side surface of the wooden board to form at least one of the tongue and the tongue and groove in the second process;

[0039] (3) a third step of laminating a decorative film on the above-mentioned synthetic resin layer; and

[0040] (4) A fourth step of folding in the above-mentioned decorative film so as to cover the entire above-mentioned synthetic resin layer and part or all of the above-mentioned tongue and groove.

[0041] Hereinafter, each process will be described with reference to the accompanying drawings.

[0042] The first process

[0043] The first process is on the plane part of the wooden board (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com