Cleaning device and cleaning method

The technology of a washing device and a washing method, which is applied in the directions of cleaning methods and utensils, chemical instruments and methods, and cleaning methods using liquids, etc., can solve problems such as difficulty in properly discharging the container 102 , uniform supply of cleaning liquid, and difficulty in cleaning end faces, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

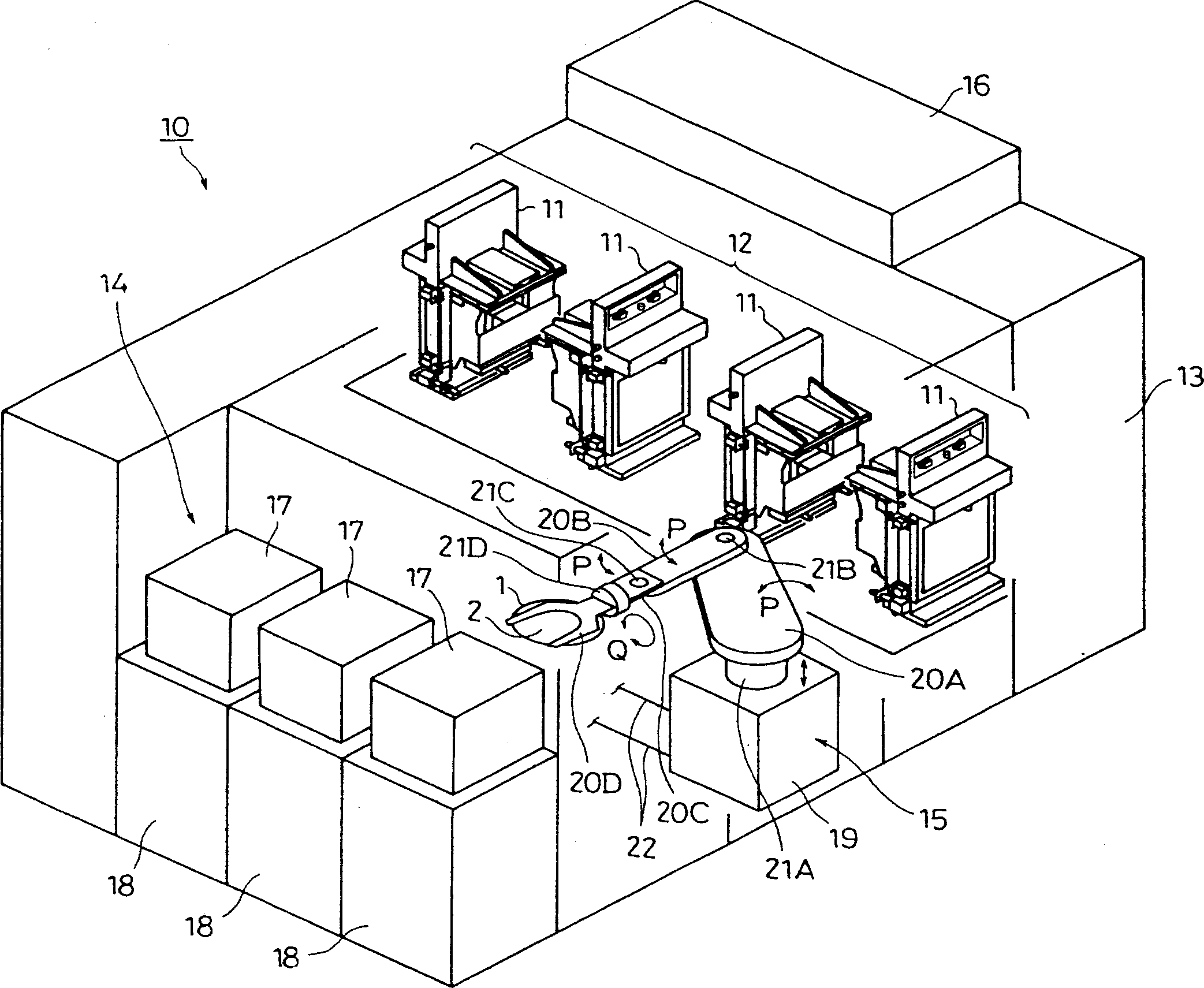

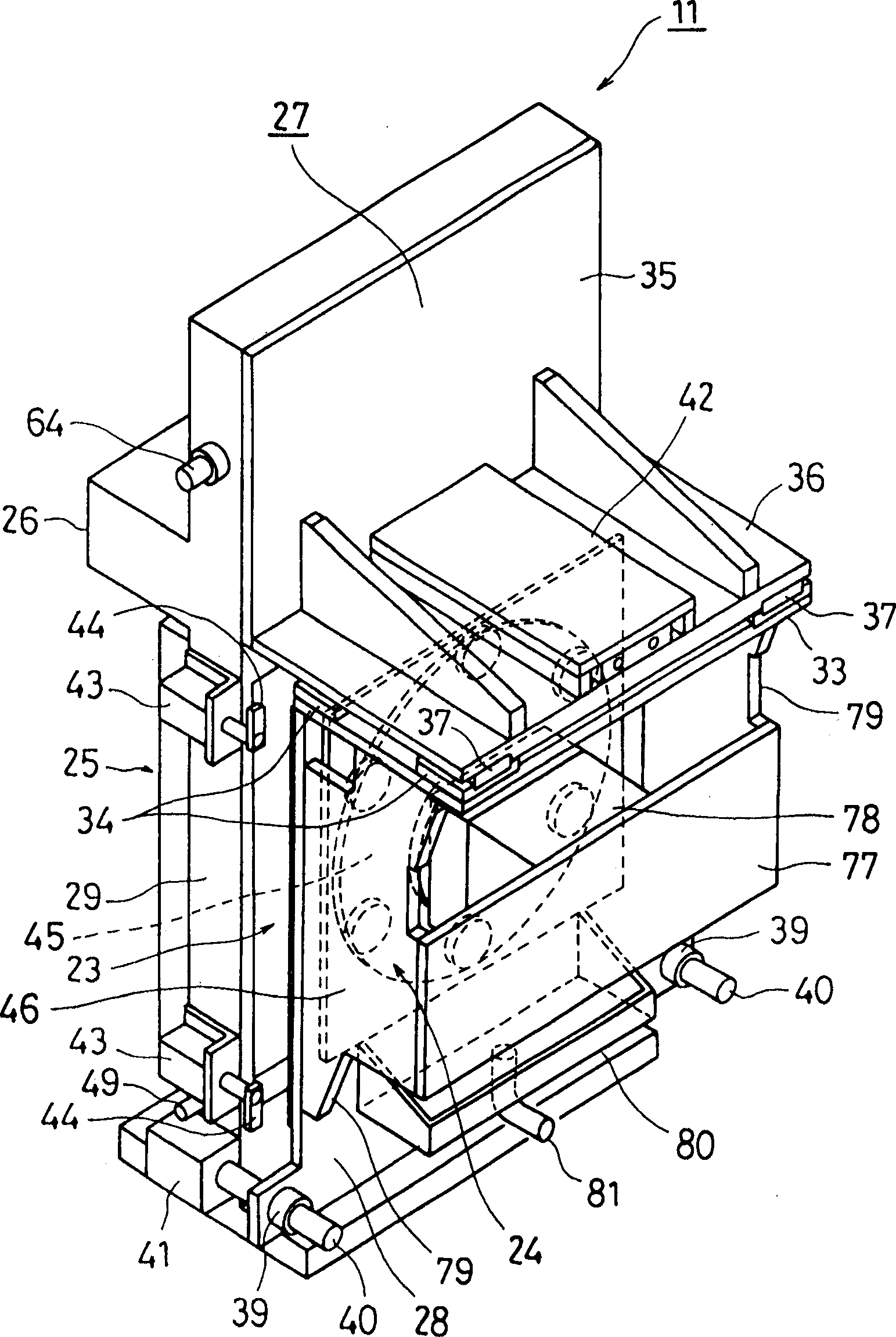

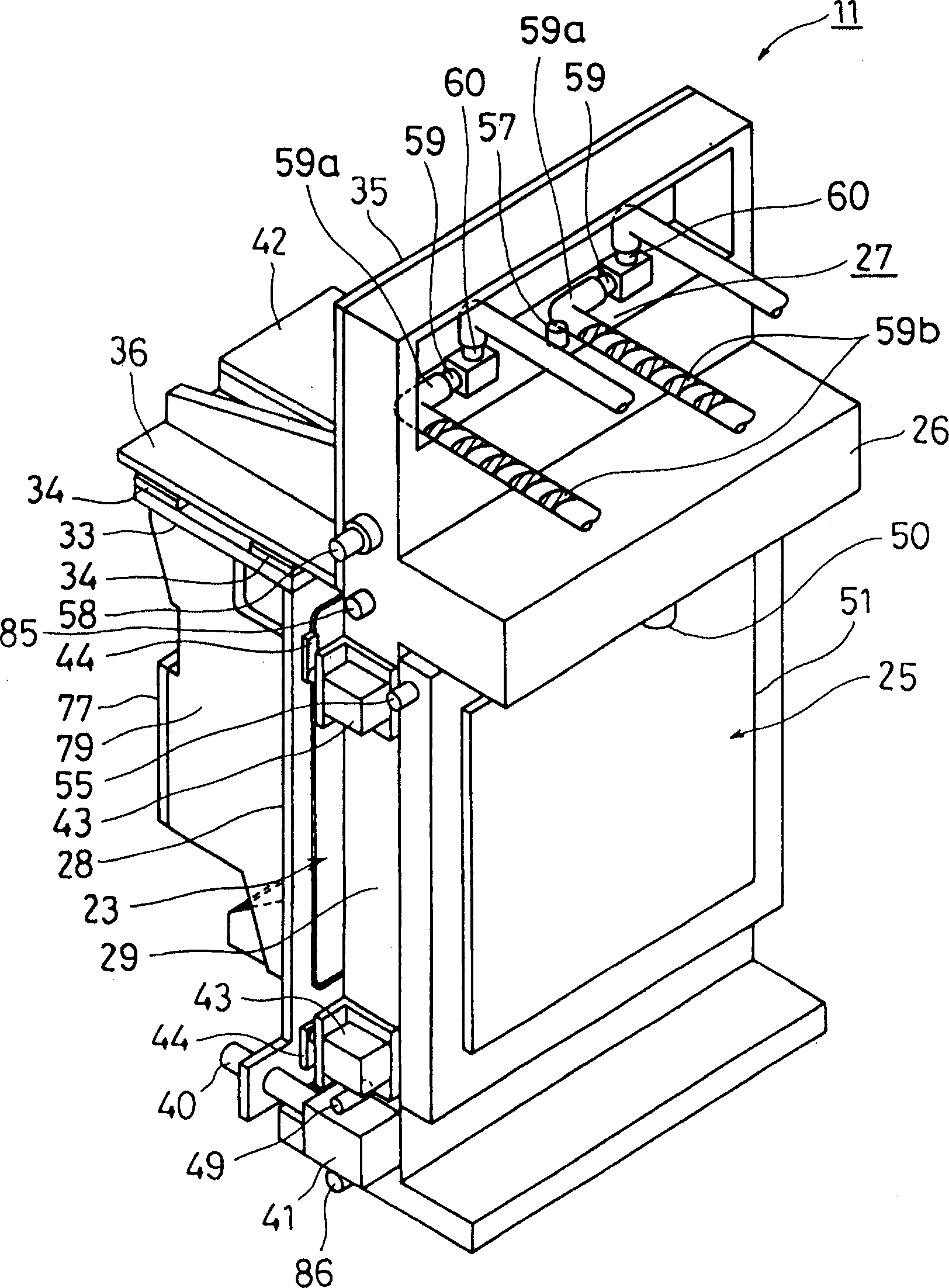

[0132] figure 1 It is a perspective view of a washing facility in which the washing apparatus according to the first embodiment of the present invention is arranged. figure 2 yes figure 1 Oblique front perspective view of the washing machine in standby state. image 3 yes figure 1 Oblique rear perspective view of the washing machine in its standby state. Figure 13is to illustrate figure 2 A schematic cross-sectional view of the principle of the washing device.

[0133] figure 1 The shown cleaning equipment 10 includes a cleaning device arrangement part 12 provided with a plurality of cleaning devices 11 (described in detail later) for cleaning semiconductor substrates (for example, wafers 1 ) as objects to be processed, and adjacent to the cleaning device arrangement part 12. The chemical solution supply part 13 arranged, the wafer supply and discharge part 14 arranged at the position facing the above-mentioned chemical solution supply part 13, the transfer robot ...

no. 2 Embodiment approach

[0201] The second embodiment ( Figure 18-23 )

[0202] Figure 18 It is an oblique front perspective view of a washing machine according to a second embodiment of the present invention. Figure 19 yes Figure 18 A side view of the cleaning apparatus with wafers carried in and out. Figure 20 yes Figure 18 A front view of the cleaning device for wafer cleaning and other processing states. Figure 21 is along Figure 20 View taken by arrow VII in . Figure 22 is to illustrate Figure 18 A brief structural cross-sectional view of the principle of the washing device. Figure 23 yes Figure 22 Partially enlarged cross-sectional view. In the second embodiment, the same parts as those in the first embodiment are denoted by the same symbols, and description thereof will be omitted.

[0203]In the cleaning device 90 of the second embodiment described above, the spot facing surface 70 provided around the opening 30 of the front wall 28 in the first embodiment and the plug 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com