Microfluidic chip with sampling probe and preparation method thereof

A microfluidic chip and probe technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of large tip section, low success rate, troublesome and other problems, and achieve the effect of simple and easy operation, convenient sampling operation and fast processing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Glass integrated probe microfluidic chip, the steps and methods of submillimeter probes are:

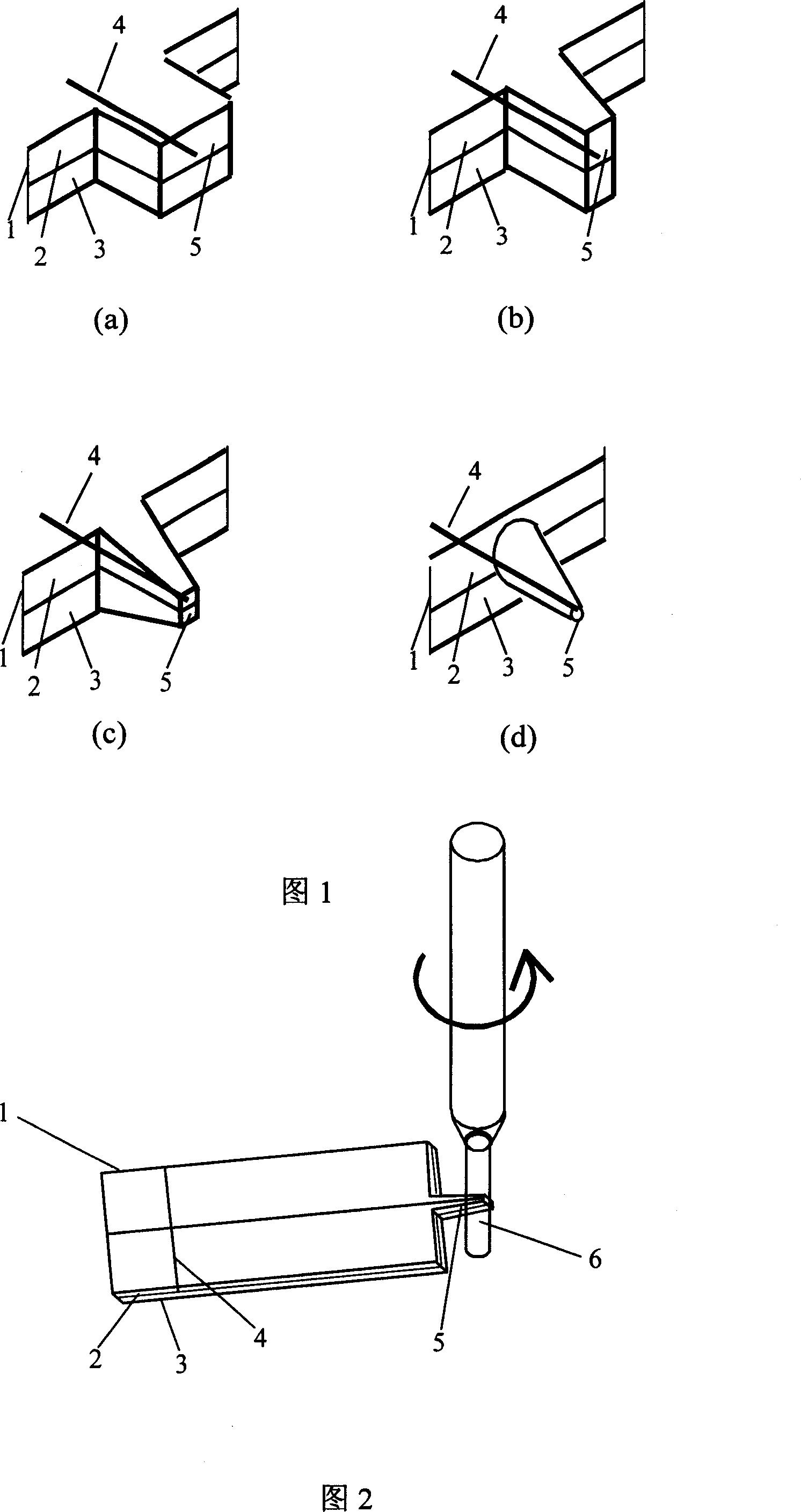

[0028] As shown in FIG. 1 , the microfluidic substrate 1 is composed of a glass upper sheet 2 and a glass lower sheet 3 etched with microchannels 4 , and the two sheets are sealed by high-temperature bonding. The channel depth ranges from 1 to 100 microns, and the width ranges from 1 to 500 microns. Before processing the probe, apply a small amount of epoxy resin glue liquid on the entrance of the end of the substrate channel 4. After curing, an epoxy resin "protection plug" about 0.5-1 mm long is formed to pre-protect the entrance of the channel to prevent When the probe is processed, glass slag enters the channel and causes channel blockage. The specific processing process of the glass microfluidic chip integrated probe is as shown in Figure 1: use a glass knife to cut the end of the substrate channel 4 to form a rectangular probe 5 prototype with a width of 2 mm x 3.4 mm h...

Embodiment 2

[0031] Glass-integrated probe-type microfluidic chip, the steps and methods of micron-scale probes are:

[0032] As shown in FIG. 1 , the microfluidic substrate 1 is composed of a glass upper sheet 2 and a glass lower sheet 3 etched with microchannels 4 , and the two sheets are sealed by high-temperature bonding. The channel depth ranges from 1 to 50 microns, and the width ranges from 1 to 50 microns. Before processing the probe, a small amount of epoxy resin glue liquid is applied to the entrance of the end of the substrate channel 4, and after curing, an epoxy resin "protection plug" about 0.5-1 mm long is formed to pre-protect the channel entrance. The process of drilling and grinding the glass microfluidic chip integrated probe with the grinding head is as shown in Figure 1: use a glass knife to cut the end of the substrate channel 4 to form a rectangular probe with a width of 2 mm x 3.4 mm high x 1-30 mm long. The prototype of needle 5 (as shown in Figure 1(a)). A cylin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com