Coupler with double-row chains

A technology of couplings and chains, applied in the direction of couplings, sliding couplings, mechanical equipment, etc., can solve problems such as time delay, troublesome process, inconvenient use, etc., to improve safety reliability and ensure accuracy , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

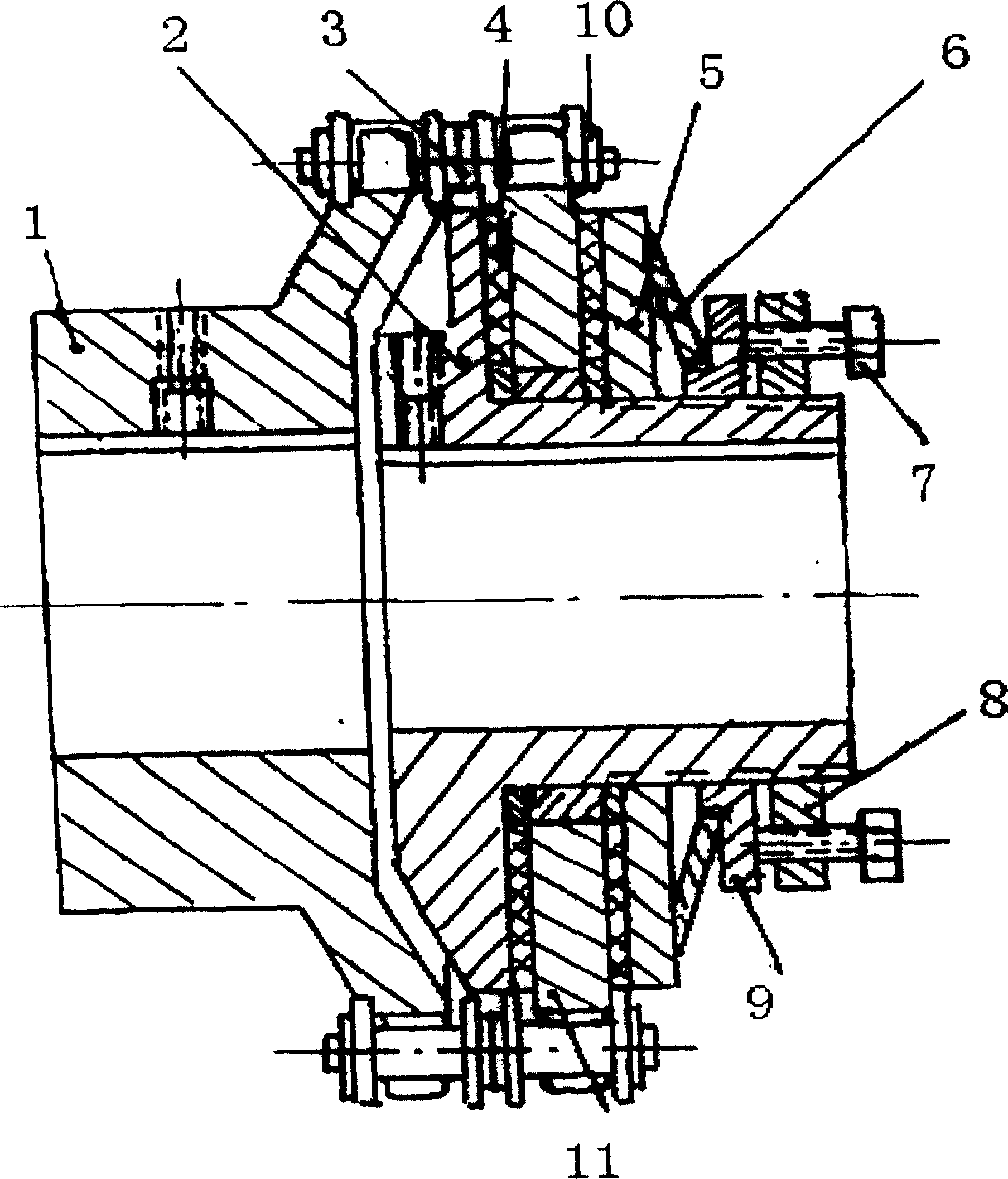

[0011] Below in conjunction with accompanying drawing, the present invention will be further described:

[0012] Such as figure 1 As shown: the present invention includes a driven sprocket 1 connected to the input shaft of the working machine, a sleeve 2 connected on the prime mover motor, and a plate sprocket 11 is also set on the sleeve 2, and the driven sprocket 1 and the plate sprocket The ring-shaped double-row chain 3 is set between the sprockets 11, there is an A friction plate 4 between the plate sprocket 11 and the sleeve 2, there is a B friction plate 10 between the plate sprocket 11 and the pressure plate, and the buffer member 6 is set on the pressure plate 5 Between the guide plate 9 , the outer side of the guide plate 9 abuts against the adjustment piece installed on the sleeve 2 .

[0013] Friction plate, plate sprocket 11 , pressure plate 5 , buffer member 6 and guide plate 9 are all sleeved on the sleeve 2 . A shaft sleeve is also provided between the plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com