Water spraying propelling device

A thruster and water jet technology, which is applied to ship propulsion, propulsion components, ship components, etc., can solve problems such as difficulty in increasing navigation speed, troublesome navigation of ships and ships, and loud noises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Describe the specific embodiment of the present invention in detail below in conjunction with accompanying drawing

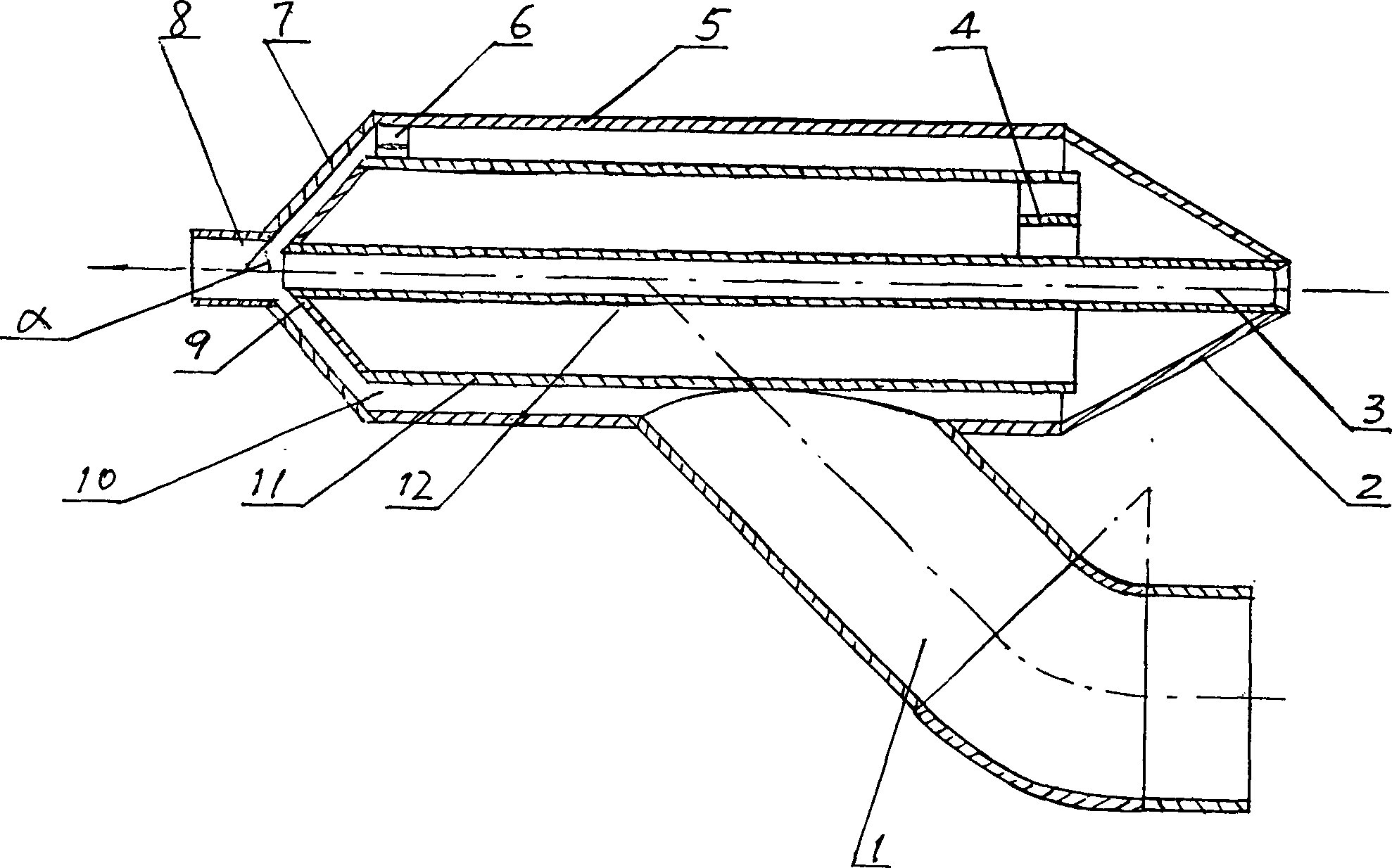

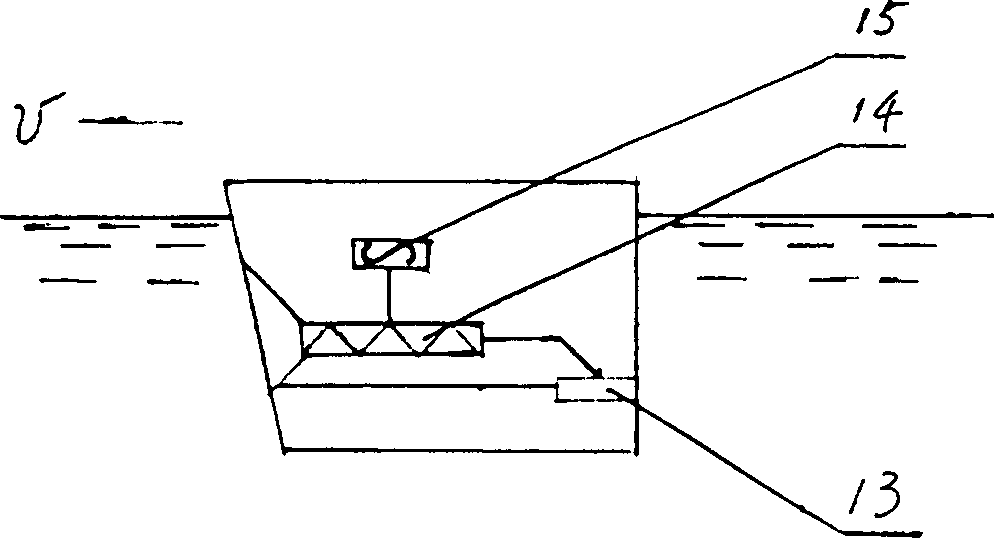

[0011] figure 1 Among them, the outer tube 5 is made of a straight tube and a large conical tube 7 connected at one end thereof, and a constricted conical tube 2 connected at the other end. Inner tube 3 is housed in outer tube 5, and inner tube 3 is connected with the outer tube 11 of small cone tube 9 by one end, and central tube 12 is set in the outer tube 11, and one end of central tube 12 and the small cone on the outer tube 11 The tubes 9 are connected and formed by fixedly connecting three uniformly distributed front support plates 4 with the inner cavity wall at the other end of the outer tube 11 . And the other end of the central tube 12 is connected with the shrinkage cone tube 2 at one end of the outer tube 5, and the outer tube 11 is fixedly connected with the inner cavity wall at one end of the outer tube 5 through three evenly distributed re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com