Method and device for reducing dust emission from lay-off elephant trunk

A technology for chute and materials, which is applied in the field of dust reduction and device for the discharge chute, which can solve the problems of endangering the health of workers, large inclination angle of the discharge chute, and large impact force of the discharge point, etc., so as to protect the health of the body, Effect of reducing dust and buffering impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

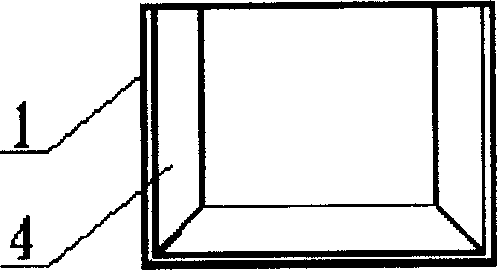

[0011] Embodiments of the present invention: adopt the method of setting damping buffer plate in the discharge chute, use the resistance produced by the damping buffer plate to the material moving in the discharge chute to reduce the descending speed of the material in the discharge chute and the material passing through the discharge chute The discharge speed at the outlet of the chute can reduce the impact force of the material on the discharge point, thereby achieving the purpose of reducing dust.

[0012] During implementation, preferably at least be installed on the lower wall plate in the pipe body (1) of the discharge chute that is provided with feed inlet (2) and discharge outlet (3) and the side wall plate on both sides 1 layer of damping buffer plate (4) arranged according to U-shaped opening; but under normal circumstances, it is better to install 5 layers of damping buffer plate (4) arranged according to U-shaped opening on the lower wall plate and the side wall pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com