Method for applying an electrical insulation

An electrical insulating layer and coating technology, which is applied in the field of spraying on ferromagnetic objects and spraying electrical insulating layers on ferromagnetic objects, can solve the problem of insufficient fixation of the armature body, high equipment cost, downtime, and considerable time spent and other problems, to achieve the effect of saving auxiliary stations, reliable tank insulation, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

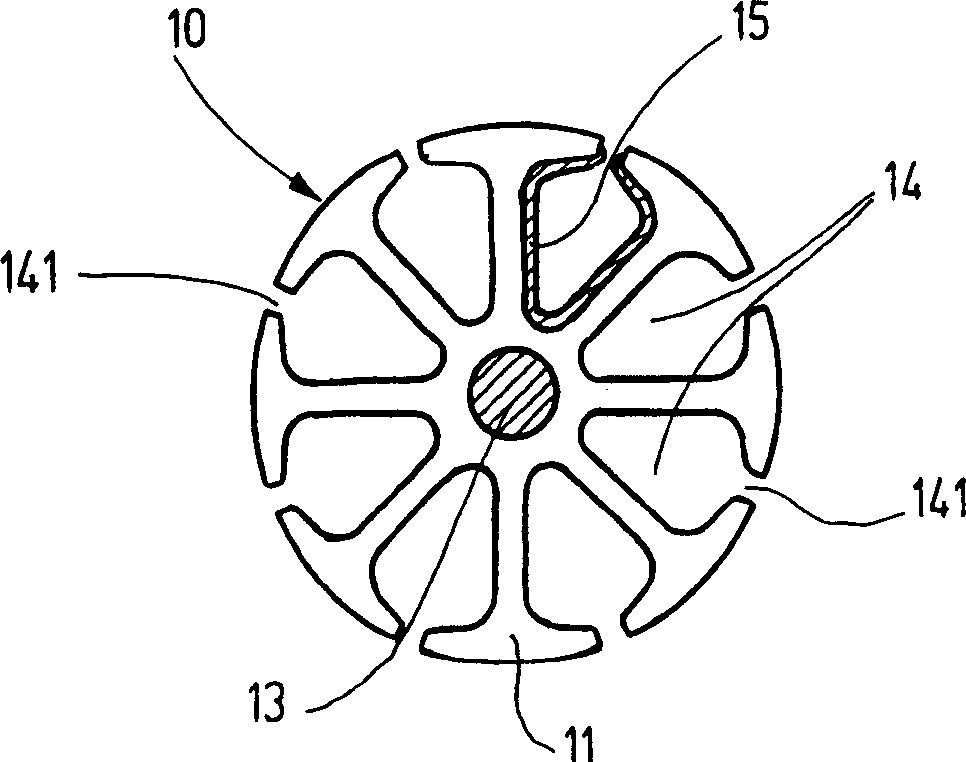

[0017] The application of an electrically insulating layer on a ferromagnetic body of a motor main part, namely a stator or rotor, with axial slots for mounting the armature winding is illustrated by means of a slotted armature body 10 of the armature of a DC motor. method. figure 2 The armature body 10 , shown in end view, consists of several molded laminations 11 , which are arranged axially one behind the other to form a so-called laminated core and are fixedly connected to one another in the axial direction. When the lamination group is not formed, the armature body 10 can also be made into a solid cylinder with a soft magnetic composite material. Armature body 10 is provided with a number of axial slots 14 equidistant over its entire circumference in a known manner for mounting armature windings.

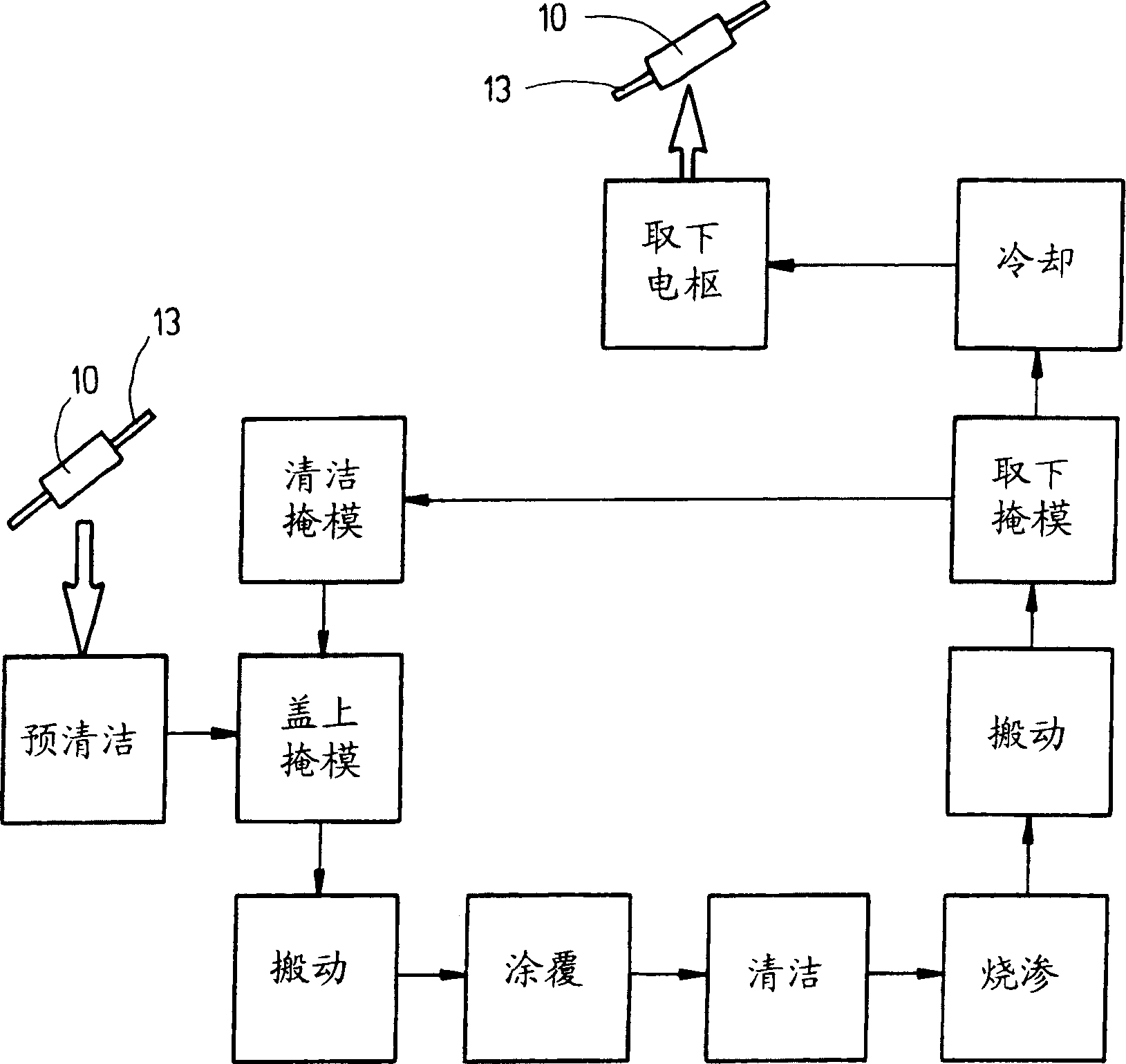

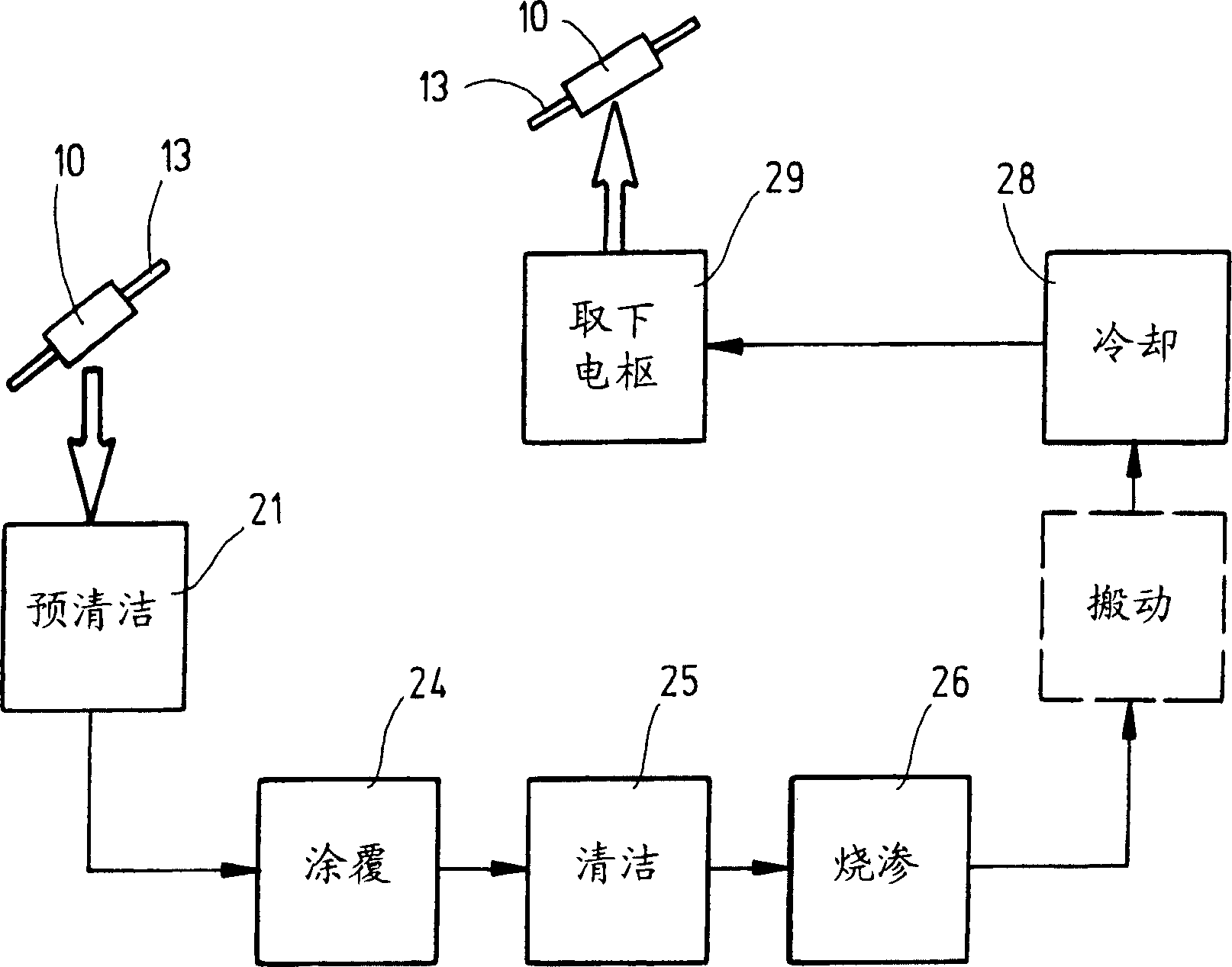

[0018] The armature body 10 press-fitted on the armature shaft 13 is "pre-cleaned" in the first process 21 ( image 3 ) to remove machining residues such as flushing chips an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com