Method for monitoring oxide layer deposition

A technology of oxide layer and silicon oxide layer, applied in semiconductor/solid-state device testing/measurement, electrical components, semiconductor/solid-state device manufacturing, etc., can solve problems such as complicated manufacturing process and inability to reflect the electrical thickness of oxide layer The effect of complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It must be noted that the structures and elements described below do not include complete structures and elements. The present invention can be implemented by various techniques and elements, and only the structures of elements required for understanding the invention are mentioned here. The following will be described in detail according to the accompanying drawings of the present invention. It must be noted that the illustrations are in a very simplified format and are not drawn to scale.

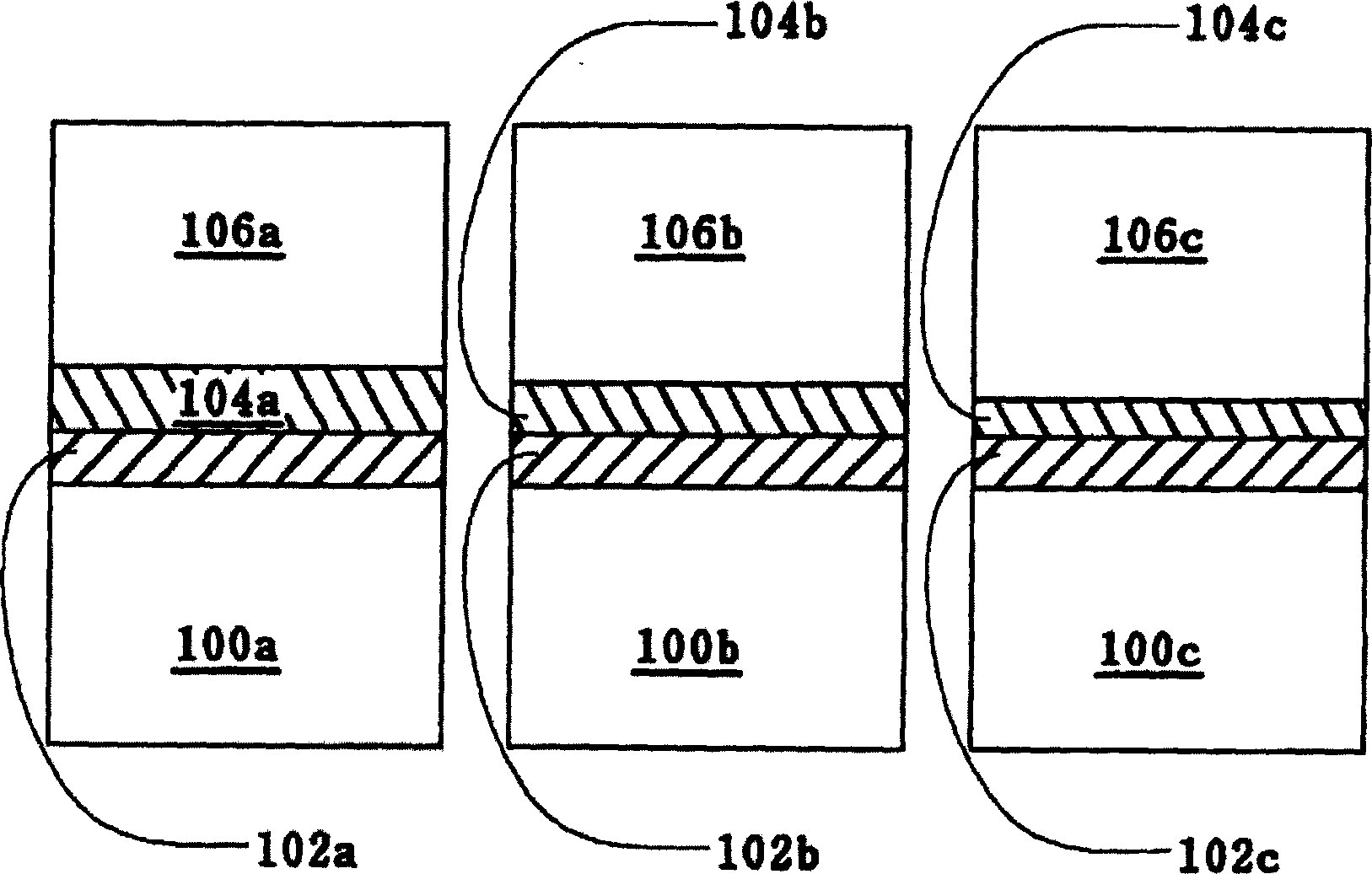

[0035] Such as figure 1 As shown and described in the prior art of the present invention, the native oxide layer on the blank wafer at the top of the furnace tube grows faster than the native oxide layer on the blank wafer at the bottom of the furnace tube, so it is deposited on the blank wafer at the bottom of the furnace tube. The native oxide layer will have a thicker oxide layer than would be deposited on the blank wafer at the top of the furnace tube.

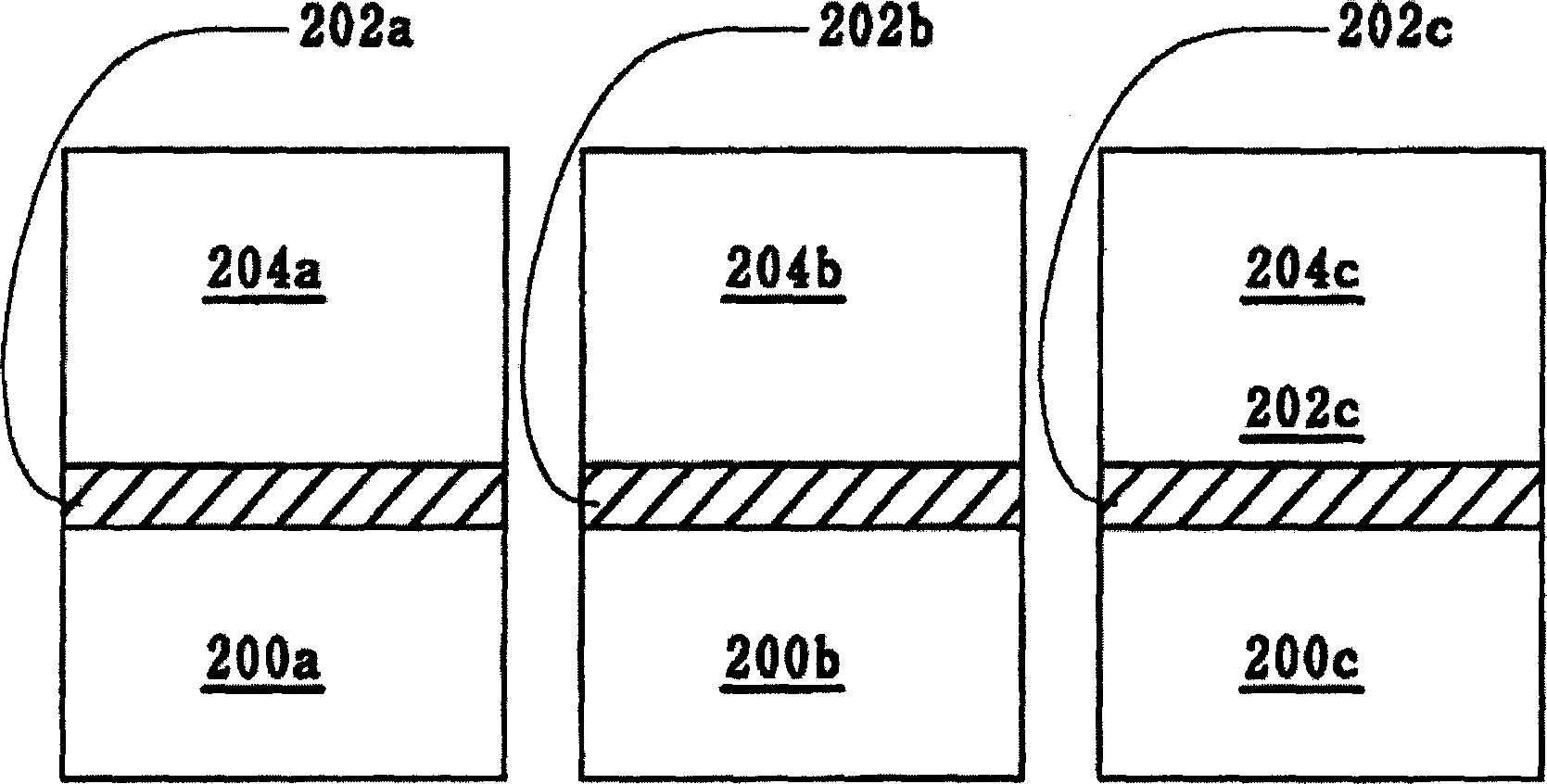

[0036] In the proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com