Kreuzkopfmotor

A cross-head, engine technology, used in engine components, engine cooling, machine/engine, etc., can solve the problems of difficult manufacturing, shortened service life, large size, etc., to achieve convenient manufacturing, reliable placement, good stress The effect of distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

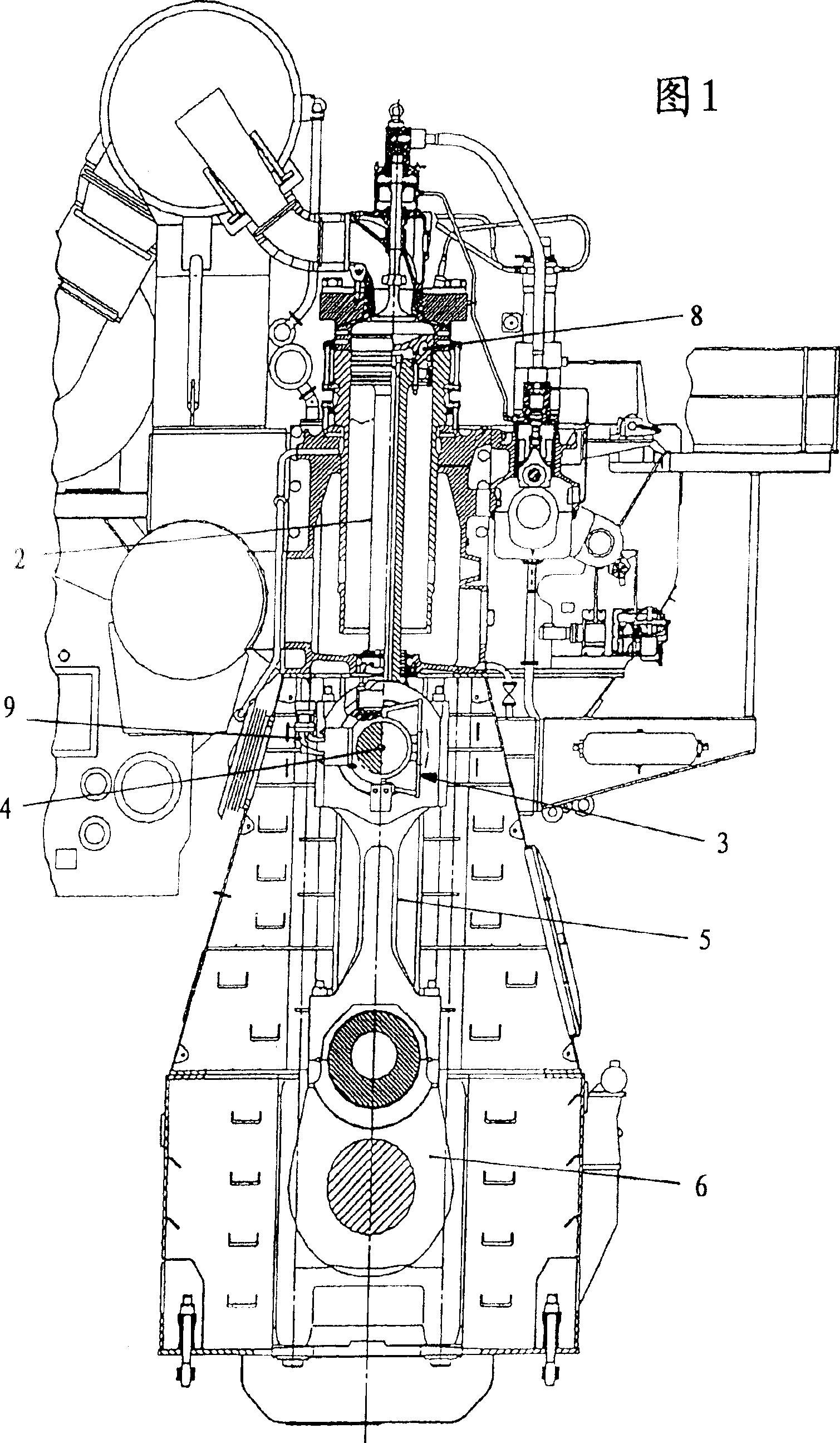

[0020] For example, the basic structure and mode of operation of two-stroke large diesel engines suitable for marine power or the like are known per se. As shown in Figure 1, engines of this type are often designed as crosshead engines. Each piston 1 is connected to a crosshead 3 via a piston rod 2 . The crosshead 3 actually forms a slide which is guided in the direction of the machine frame parallel to the piston pin. The crosshead 3 comprises a crosshead journal 4 arranged perpendicular to the axis of the piston rod 2, in which the piston rod 2 is fixed and on which a connecting rod 5 is supported, which The rod 5 connects the crosshead 3 to a crankshaft 6 which is arranged in the lower region of the engine block.

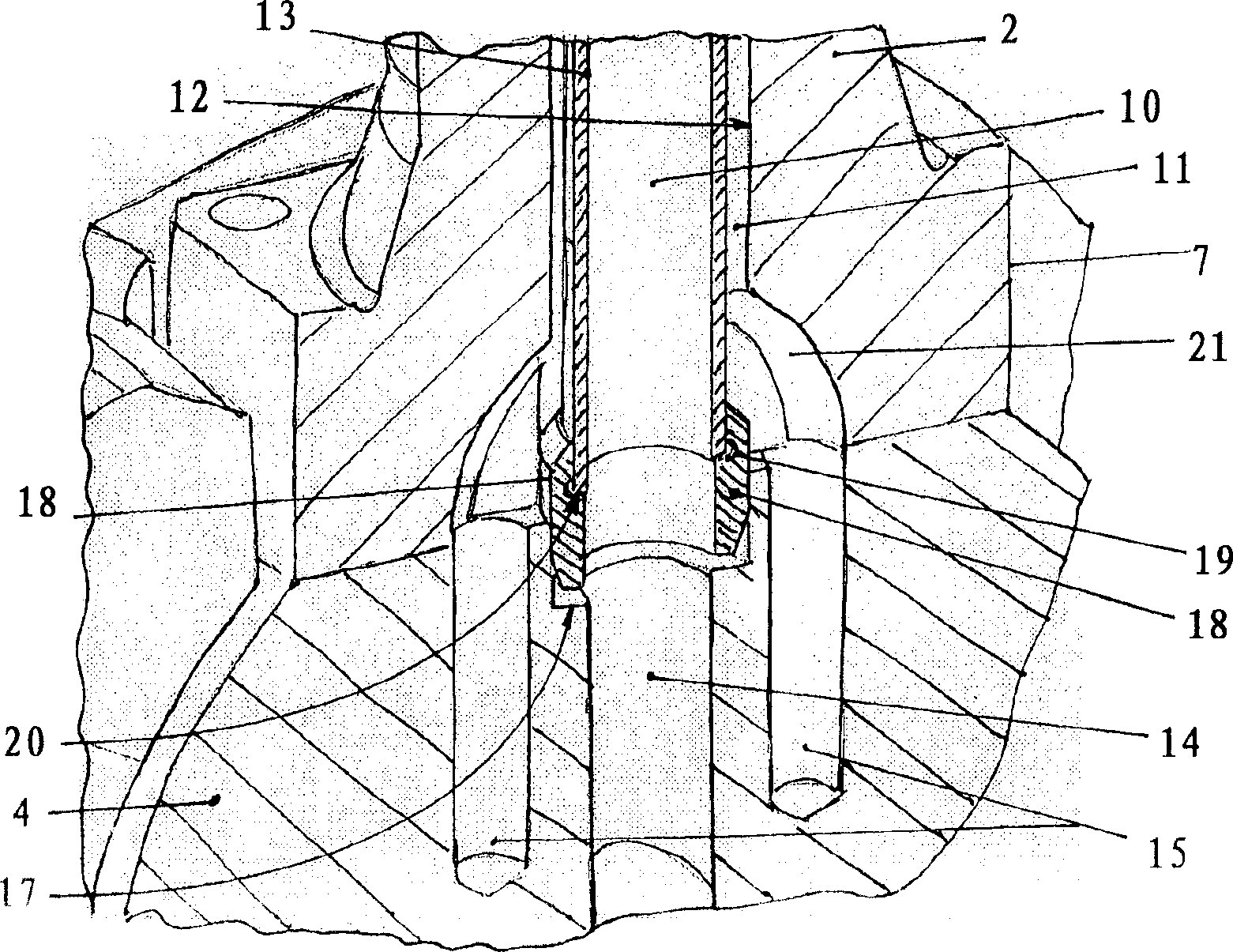

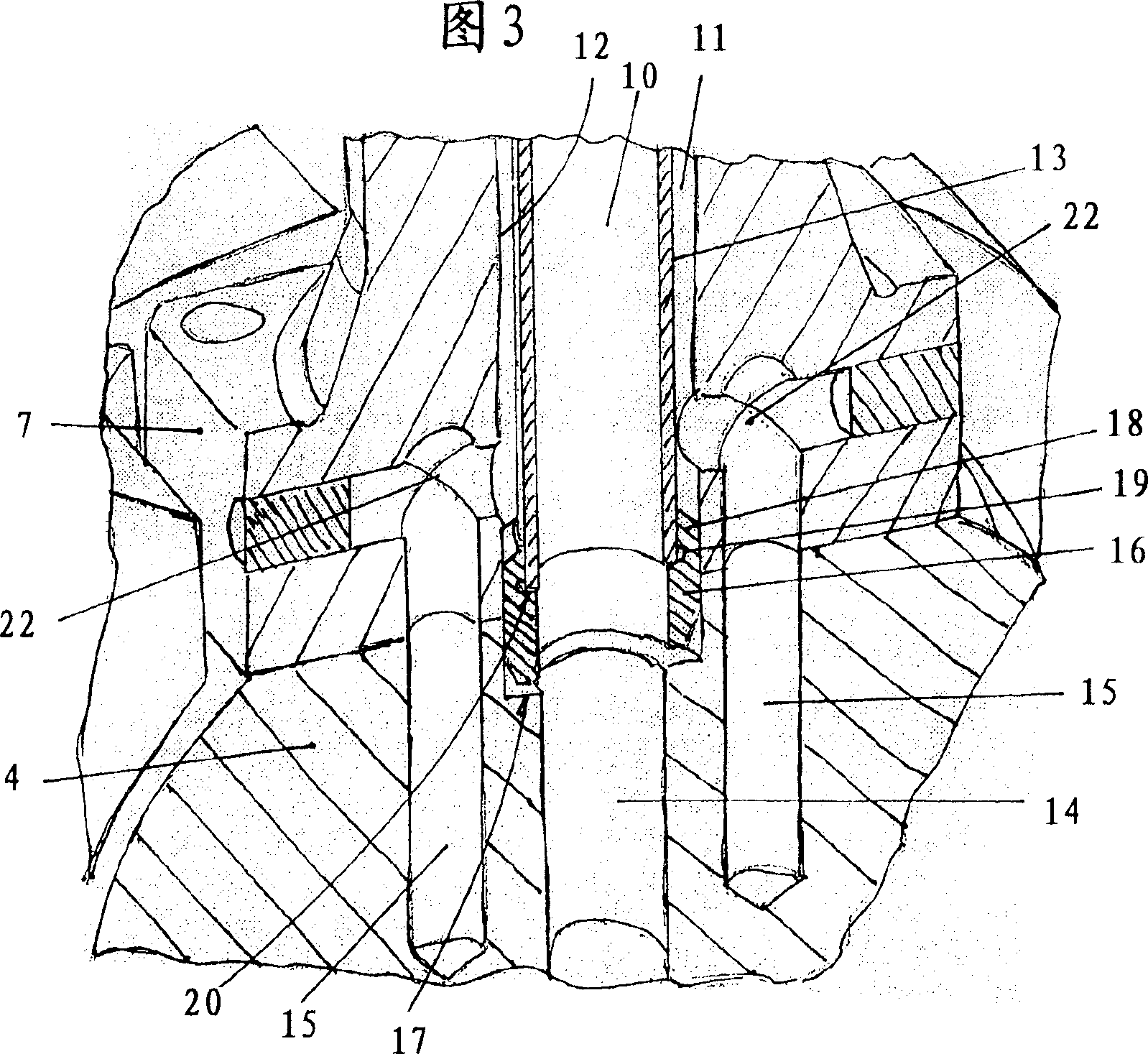

[0021] as other figure 2 As shown in -4, the piston rod 2 is provided with a flange 7 at the lower end, which abuts against a matching bearing surface of the crosshead journal 4 with its lower end surface. The flange 7 has holes for the passage of bolts, by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com