Film forming device, film forming method, method and apparatus for fabricating self-emission device

A self-luminous, film-forming technology, applied in the field of manufacturing devices, can solve problems such as electrode short circuit, component degradation, and adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

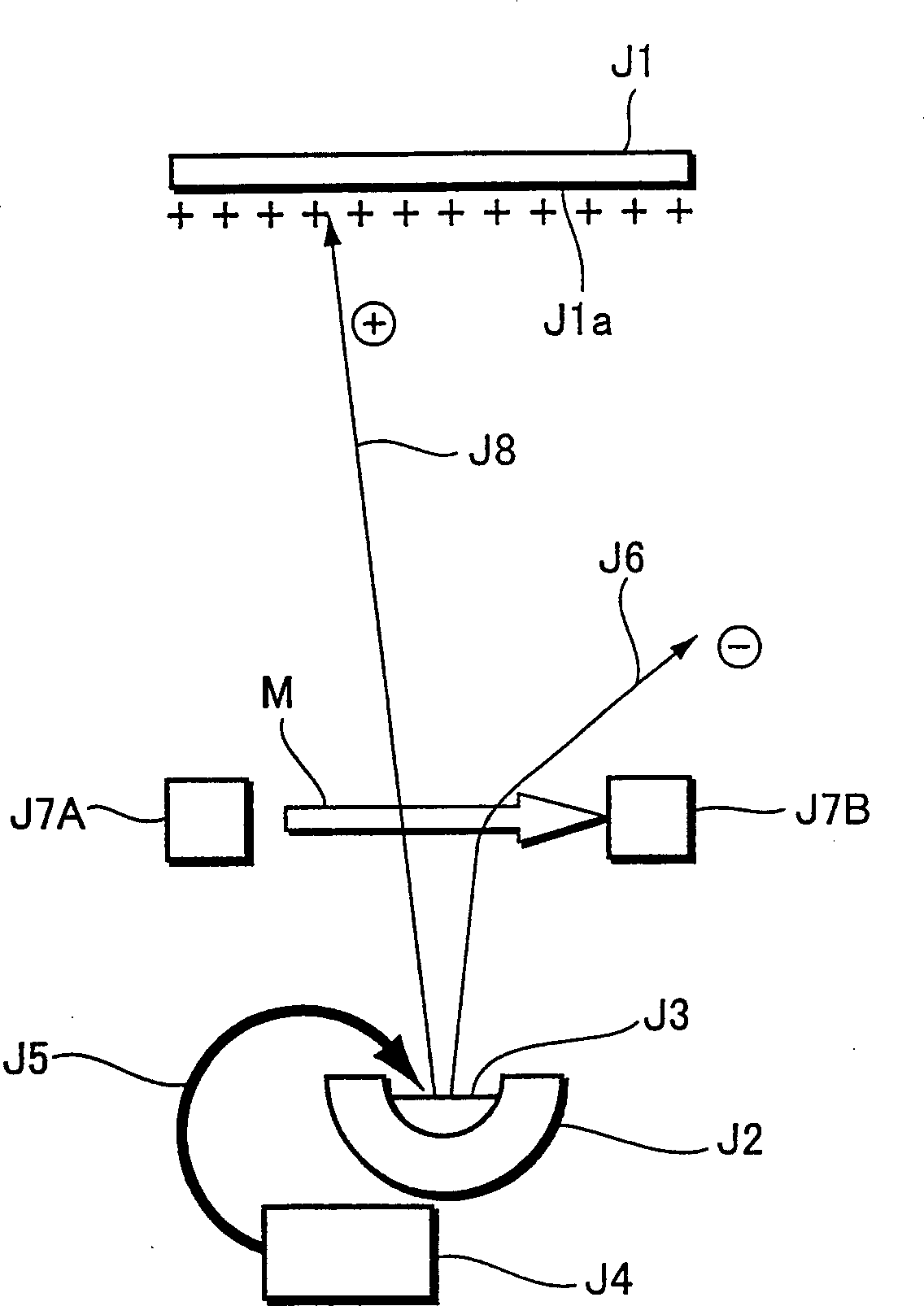

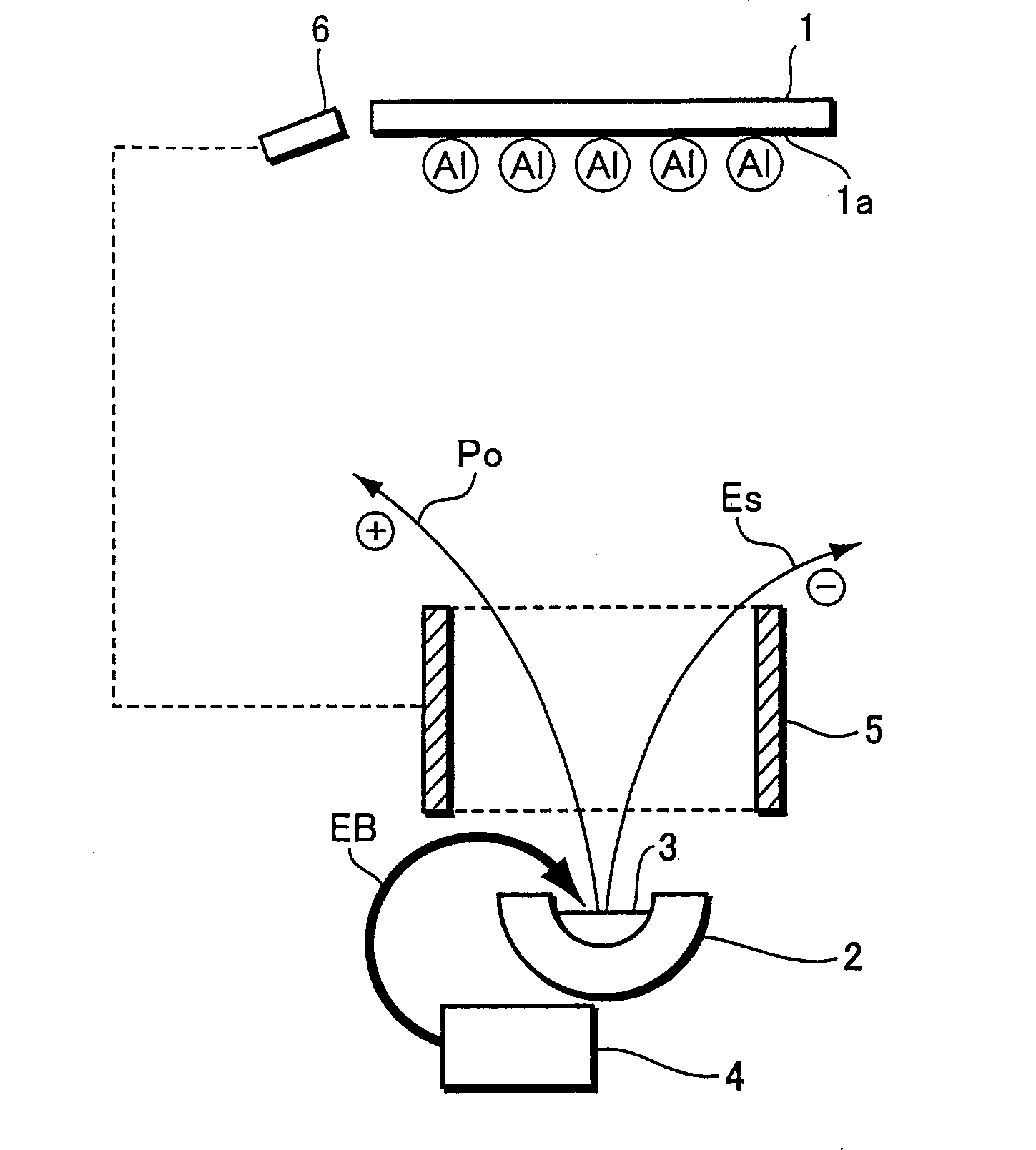

[0026] Embodiments of the present invention will be described below with reference to the drawings. figure 2 It is an explanatory diagram for explaining a film forming method and a film forming apparatus according to an embodiment of the present invention.

[0027] This film-forming device forms a metal thin film such as Al on the film-forming surface 1a of the substrate 1 by electron beam evaporation, and has the function of irradiating the metal material 3 accommodated in the film-forming source 2 with an electron beam generator (electron gun). The electron beam irradiation unit 4 of the electron beam EB melts the metal material 3 by irradiation of the electron beam, and the generated metal vapor is vapor-deposited on the film-forming surface 1a of the substrate 1 to form a metal thin film, and also has a charge trajectory changing unit 5. It changes the trajectory of electrons ES (secondary electrons or bounced electrons) and positive ions Po generated by irradiating electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com