Exposure method and apparatus

An exposure method and technology of an exposure device, which are applied to the exposure device of a photoengraving process, an exposure method of a radiation-sensitive mask, a microlithography exposure device, etc., can solve the problem of increased hardening shrinkage, excessive irradiation energy, and inability to completely remove the Protective layer and other problems to achieve good plating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

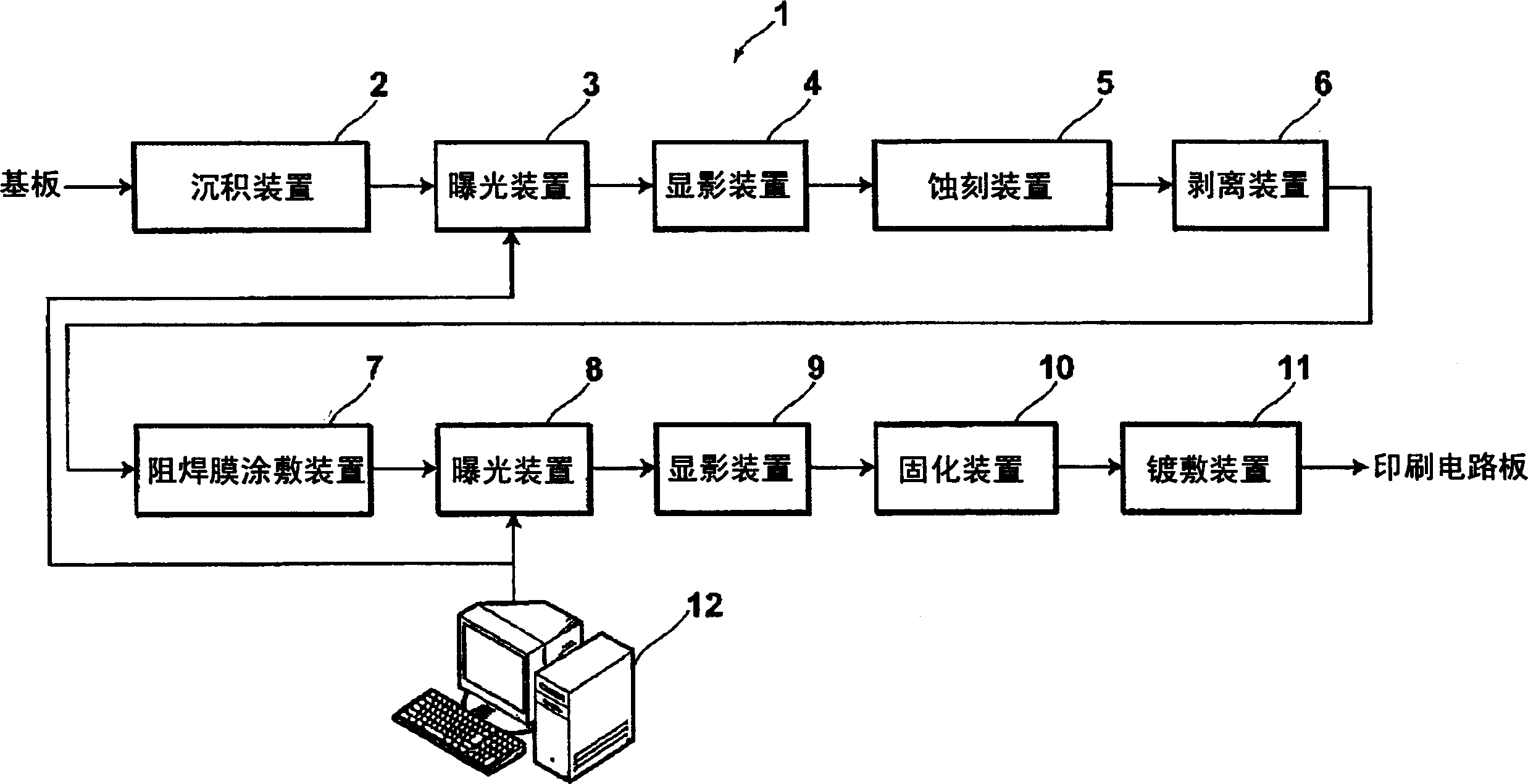

[0065] Embodiments of the present invention will be described below with reference to the drawings. figure 1 It is a schematic block diagram showing the configuration of a printed circuit board manufacturing system including an exposure apparatus according to an embodiment of the present invention. like figure 1 As shown, the printed circuit board manufacturing system 1 of this embodiment is equipped with: a lamination device 2, which laminates a photosensitive adhesive film (DFR) on a substrate formed of copper foil to form a protective layer; an exposure device 3, which exposes Matching display pattern; developing device 4, which develops the exposed protective layer to form a protective pattern with the same shape as the wiring pattern; etching device 5, which etches the copper foil on the substrate on which the protective pattern is formed to form a wiring pattern Stripping device 6, which peels off the protective layer remaining on the substrate after etching; Solder res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com