Foundation pit steel pipe connecting device

A connecting device and steel pipe technology, which is applied in the connection of scaffolding, infrastructure engineering, building structure support, etc., can solve problems such as insufficient length of standpipe, thread wear of bolts, and threats to the safety of operators, so as to improve construction efficiency, The effect of saving construction costs and eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

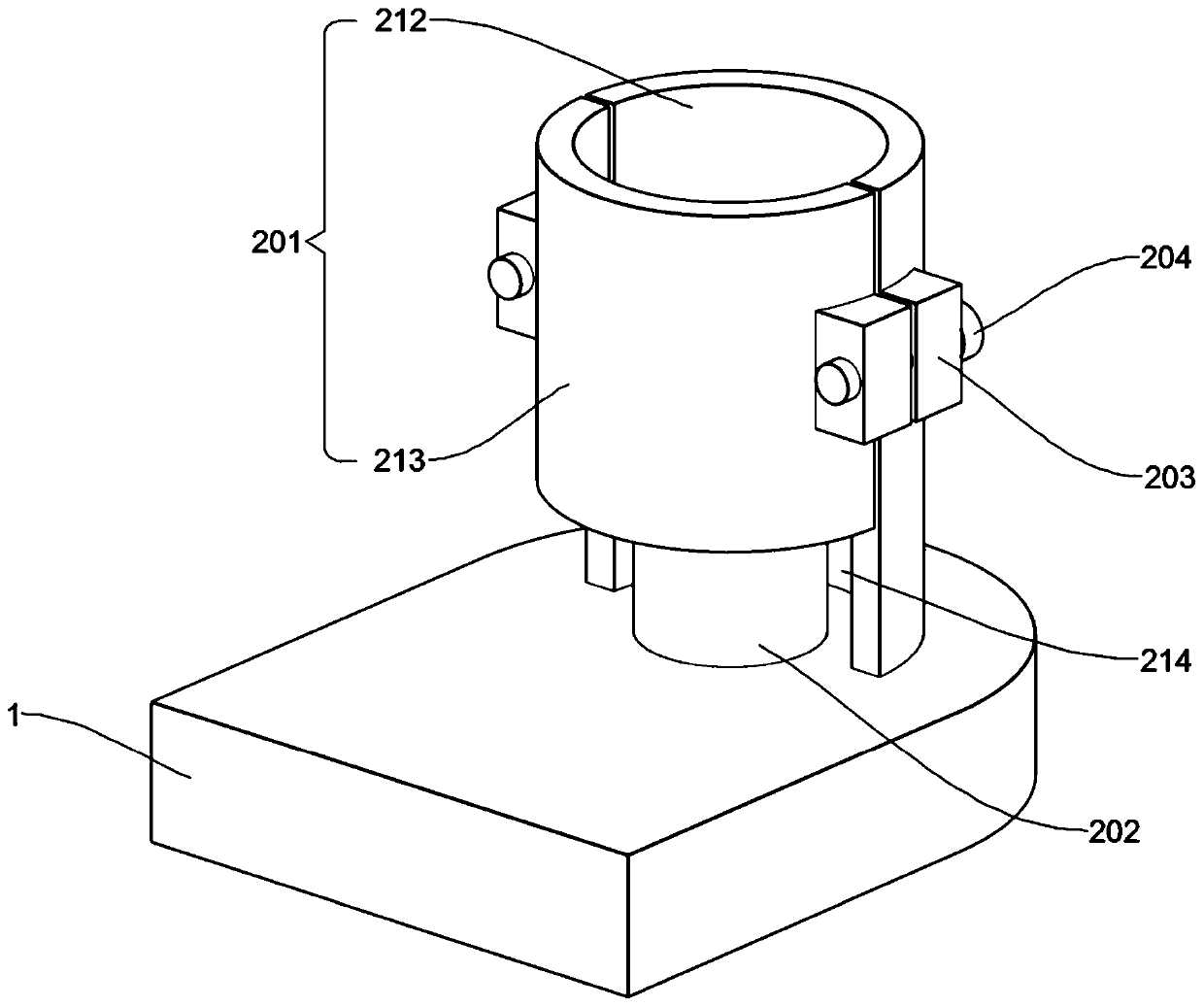

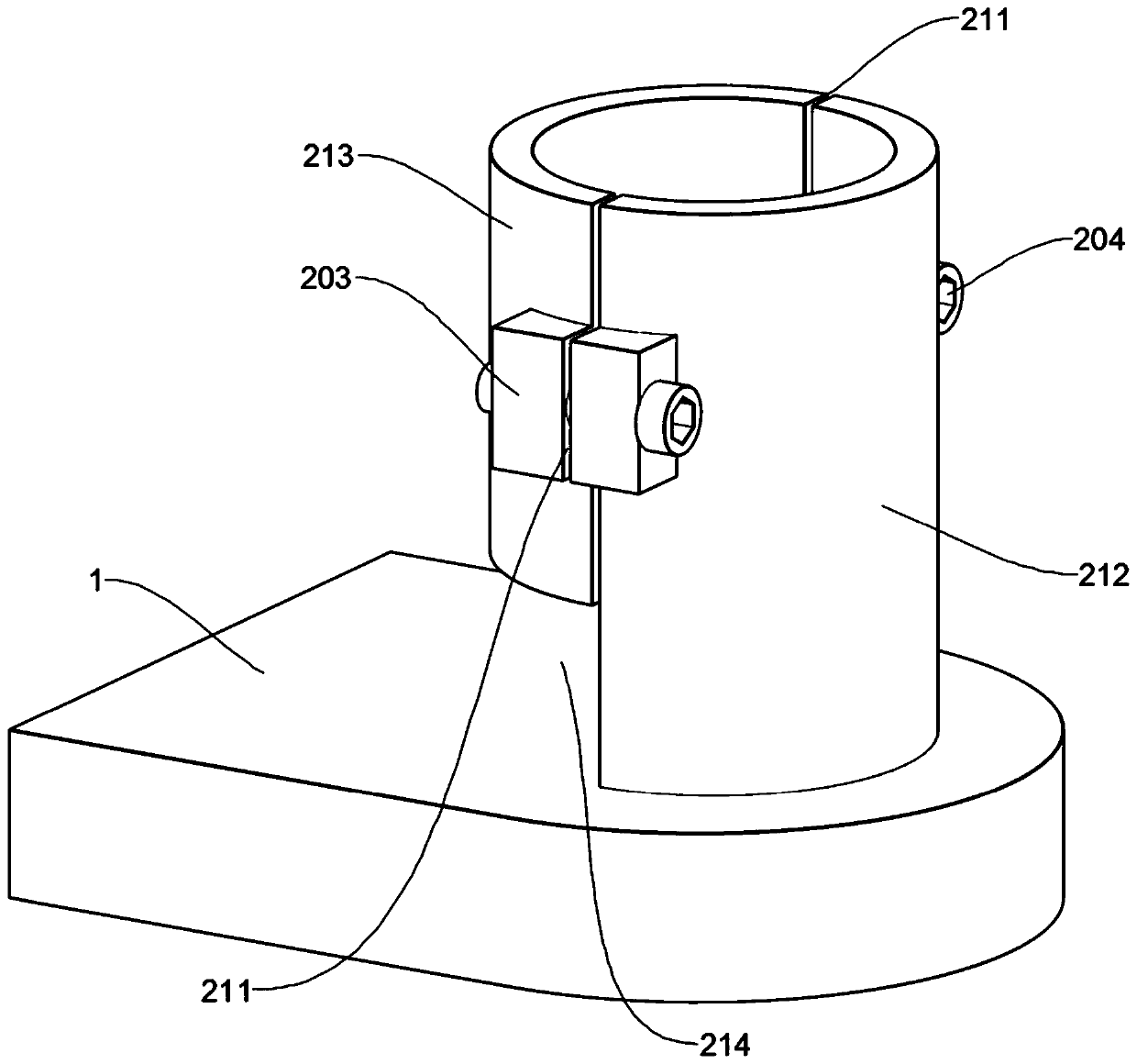

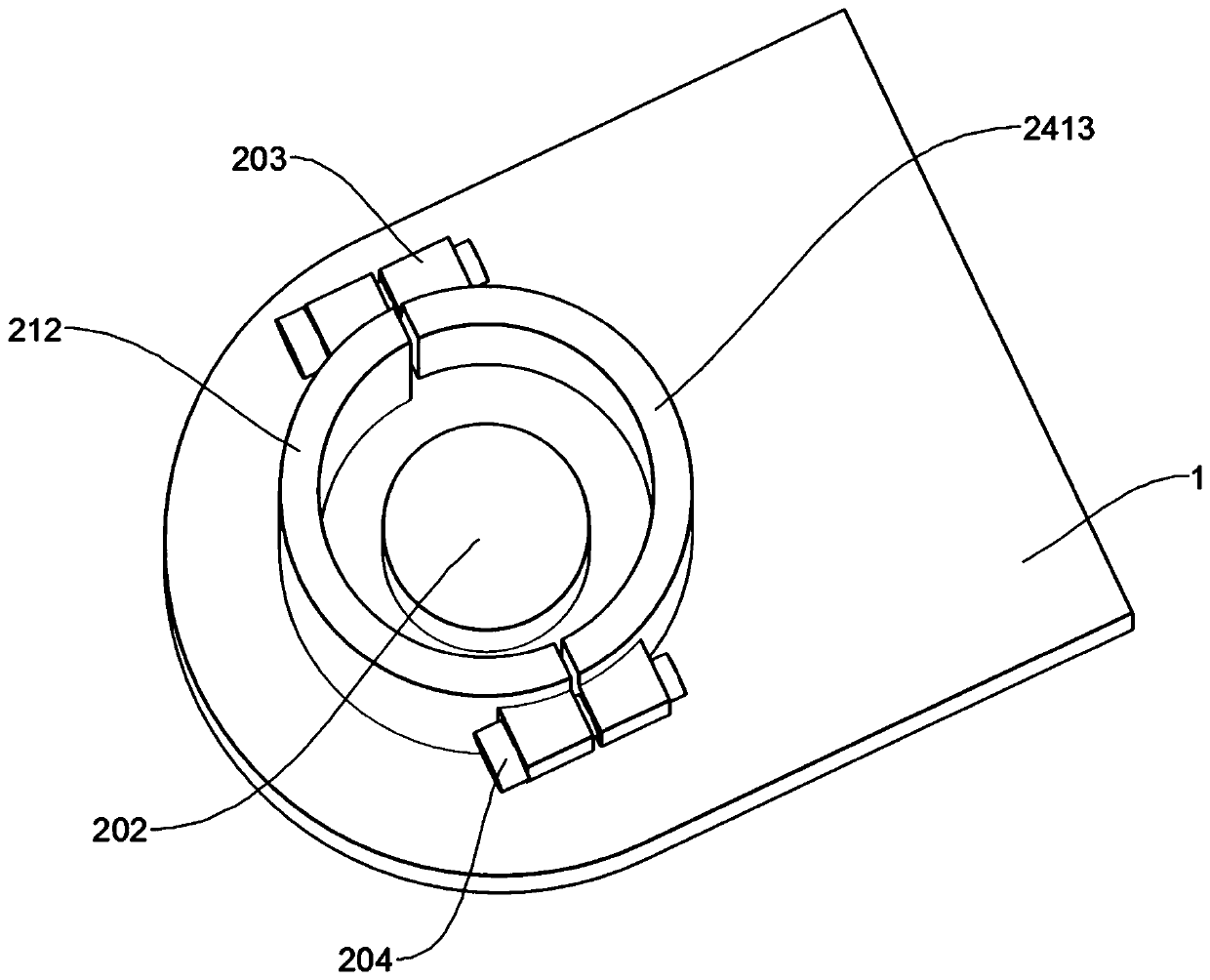

[0046] The present embodiment is a structure of a foundation pit steel pipe 3 connecting device, such as figure 1 , figure 2 , image 3 As shown, it includes a thick iron sheet 1 and a limiting structure 2, the limiting structure 2 is installed on the thick iron sheet 1, and the limiting structure 2 is integrally formed with the thick iron sheet 1, the limiting structure 2 The whole is a cylinder, and a thick iron sheet 1 and a limiting structure 2 form a component unit. The limiting structure 2 includes a limiting cylinder 201, a limiting column 202, a limiting block 203, and a bolt 204. The positioning column 202 is installed on the thick iron sheet 1, and the limiting cylinder 201 wraps the limiting column 202 and is installed on the thick iron sheet 1, and the axis of the limiting column 202 and the axis of the limiting cylinder 201 Coincidentally, the diameter of the limit post 202 is smaller than the inner cylinder diameter of the limit tube 201, that is, there is a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com