Printed circuit board and formation method

A technology of printed circuit boards and substrates, which is applied in the direction of printed circuits, printed circuit manufacturing, printed circuit components, etc., and can solve problems such as unevenness of the front of printed circuit boards, inability to fully absorb solder, holes and overflowing glue, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

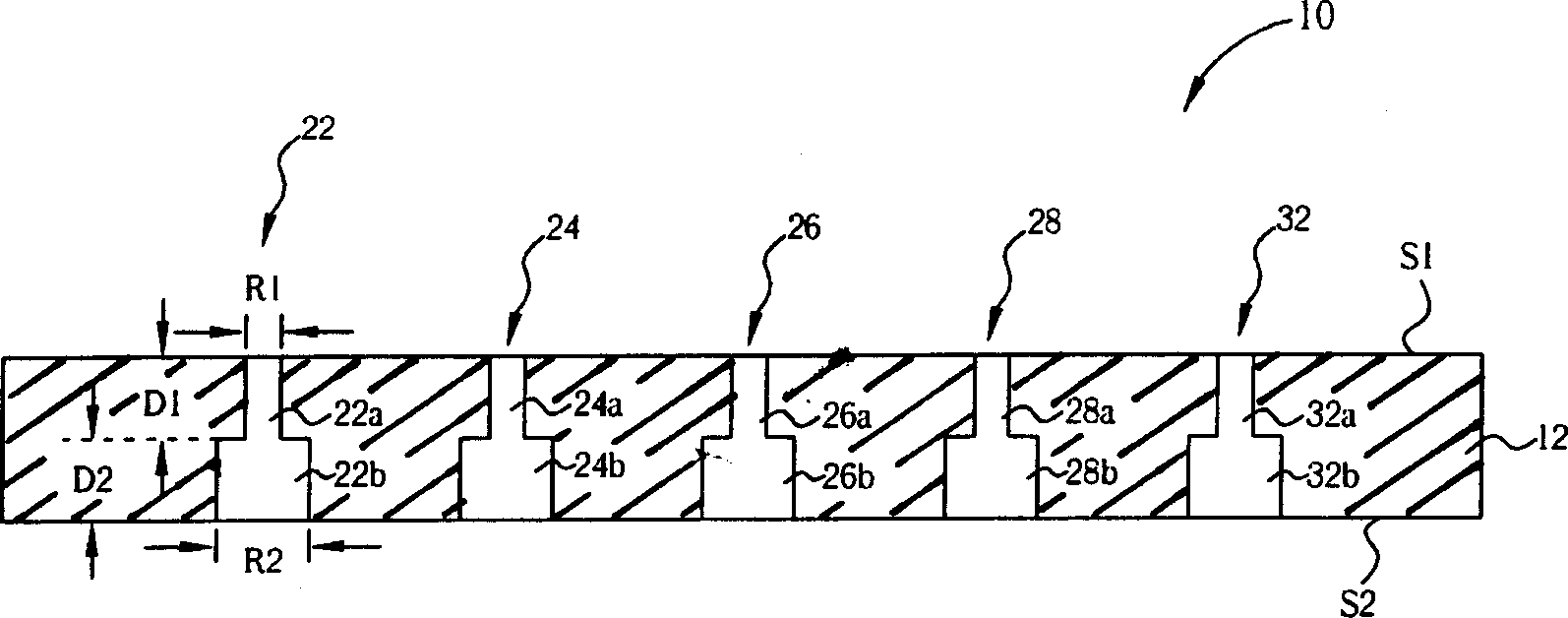

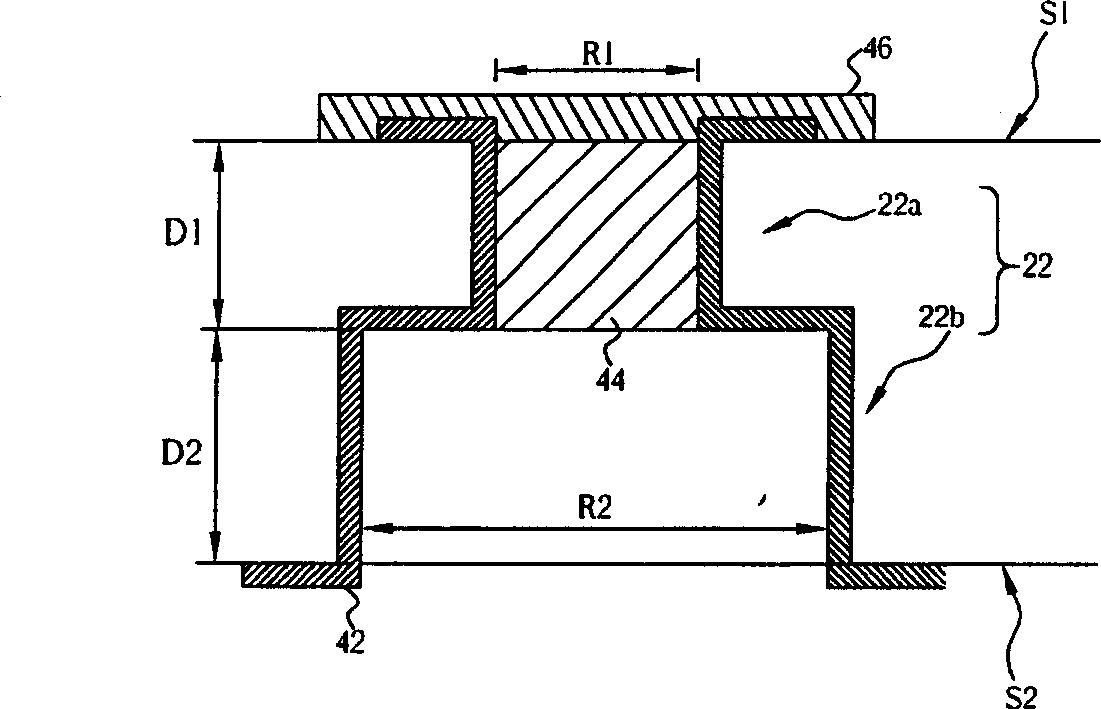

[0020] see figure 1 , figure 1 It is a sectional view of an embodiment of the printed circuit board 10 of the present invention. In this embodiment, the printed circuit board 10 includes a substrate 12 and a conductive layer. The substrate 12 has a surface S1 , a surface S2 and a plurality of through holes 22 , 24 , 26 , 28 , 32 . The through holes 22, 24, 26, 28, 32 can be divided into upper and lower parts according to their diameters, which are respectively 22a and 22b, 24a and 24b, 26a and 26b, 28a and 28b, 32a and 32b. And the upper half 22a, 24a, 26a, 28a, 32a of the through holes 22, 24, 26, 28, 32 in this embodiment all have the same diameter R1 and depth D1, and the through holes 22, 24, 26, 28, The lower halves 22b, 24b, 26b, 28b, 32b of 32 all have the same diameter R2 and depth D2, and the diameter R2 is larger than the diameter R1. In addition, the function and style of the conductive layer will be described in detail below.

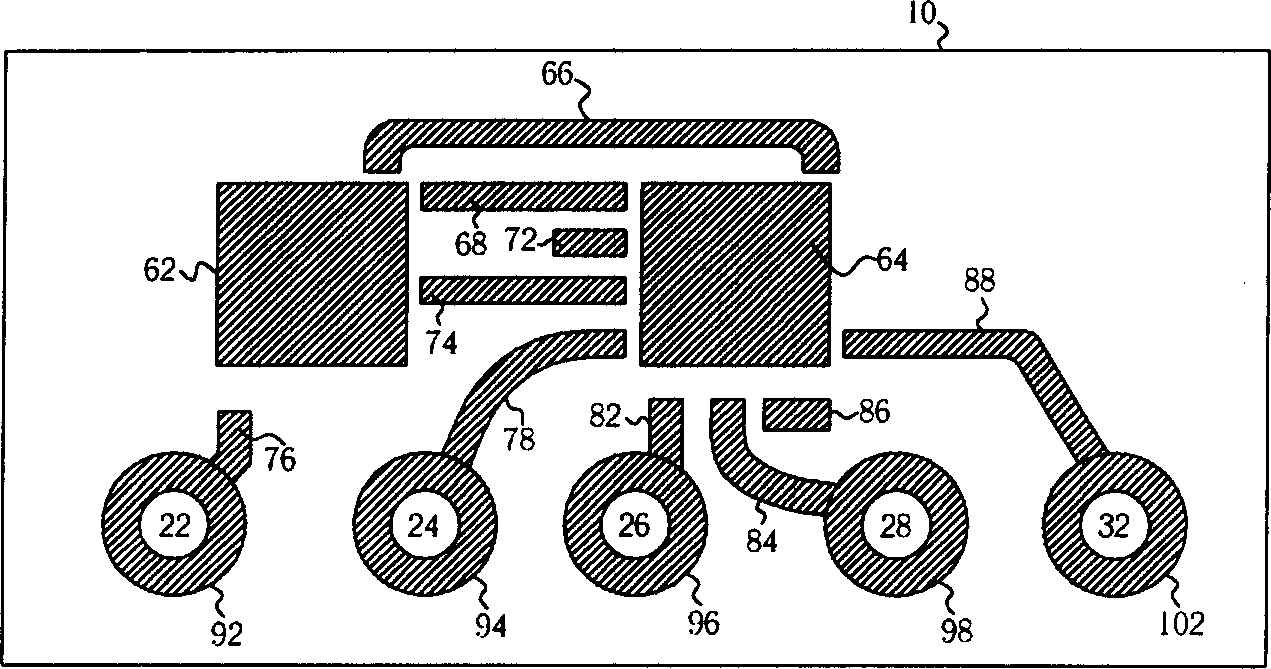

[0021] see figure 2 , figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com