Down air-exhaust type oil-fume removing device

A technology for exhausting oil fume and oil fume, which is applied in the direction of oil fume removal, heating methods, household heating, etc., can solve the problems of oil fume blocking, unsatisfactory emission effect, large energy consumption, inhalation, etc., and achieves benefits to human health , Good discharge effect, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

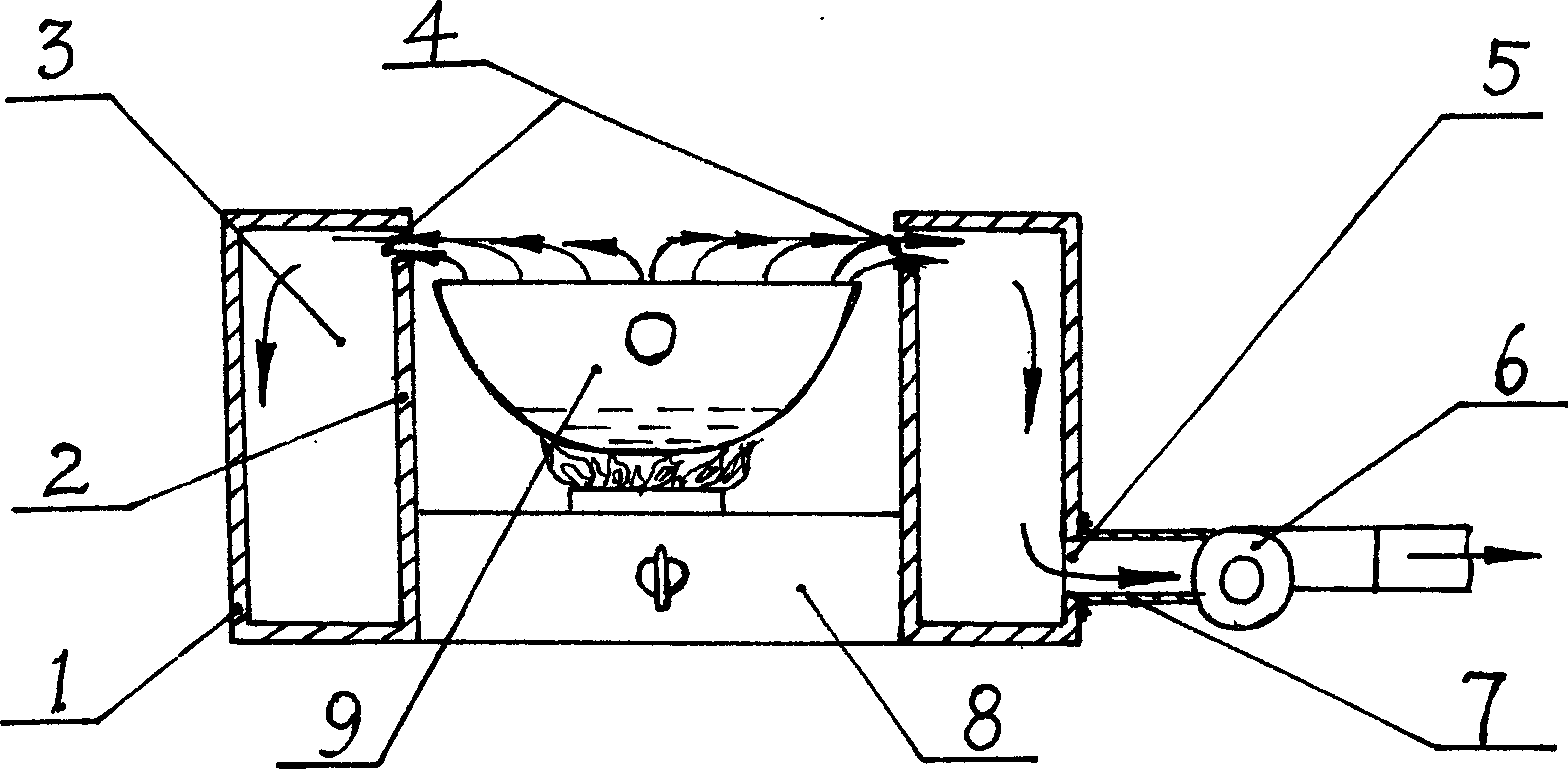

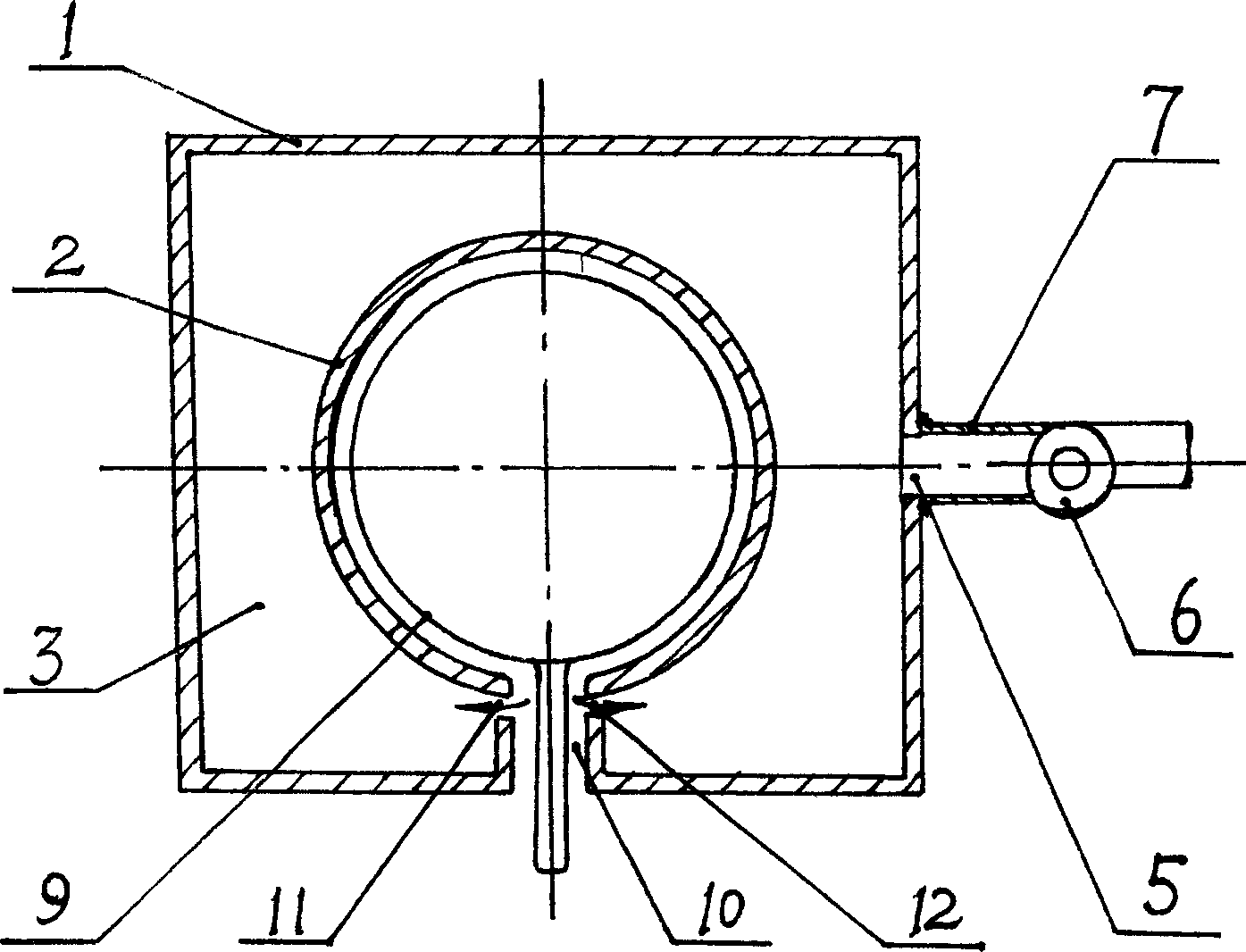

[0024] Example 1, in figure 1 The schematic diagram of the structure shown, figure 2 The schematic top view and image 3 In the schematic diagram of the partial structure shown, the present invention includes an outer casing 1 and a cylindrical cooker enclosure 2 inside it, and the outer casing 1 and the cooker enclosure 2 form a cooker enclosure with an oil fume exhaust cavity 3, Wherein, between the outer casing 1 and the annular upper edge of the cooker coaming plate 2, there are oil fume suction and discharge ports 4 distributed around the oil fume diffusion surface, and the oil fume suction and discharge ports 4 are The continuous annular suction and discharge port is located slightly higher than the position of the oil fume diffusion surface (that is, the position of the upper opening of the cooker). Fume port 5. The negative pressure source is an exhaust fan 6 , and the exhaust fan 6 is arranged on the oil fume exhaust pipe 7 communicating with the oil exhaust fume ...

Embodiment 2

[0025] In Embodiment 2, the present invention has the same structure as that described in Embodiment 1, except that an oil fume filter is added. exist Figure 4 In the schematic diagram of the partial structure shown, the present invention also includes an oil fume filter 13, which is arranged at the oil fume outlet 5 on the outer casing 1 to filter and purify the oil fume, and its material is generally Non-woven fabric, but when other materials are used, it also belongs to the protection scope of the present invention.

Embodiment 3

[0026] Embodiment 3, the present invention has the same structure as Embodiment 1 except that a deflector for oil fume discharge is added. exist Figure 5In the schematic diagram shown, the present invention also includes an arc-shaped oil fume discharge deflector 14, which is arranged at the inner cavity at the upper corner of the outer side formed by the upper cover plate and the outer shroud of the outer casing 1, and is in the direction of the above-mentioned The concave streamline shape in the upper corner direction of the outer side can reduce the diversion resistance to the inhaled oil fume, so that it can be smoothly diverted and discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com