Polishing apparatus and polishing method

A technology for polishing devices and polishing surfaces, which is applied in the direction of grinding devices, electrical components, grinding machine tools, etc., and can solve the problems of polishing treatment application and influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

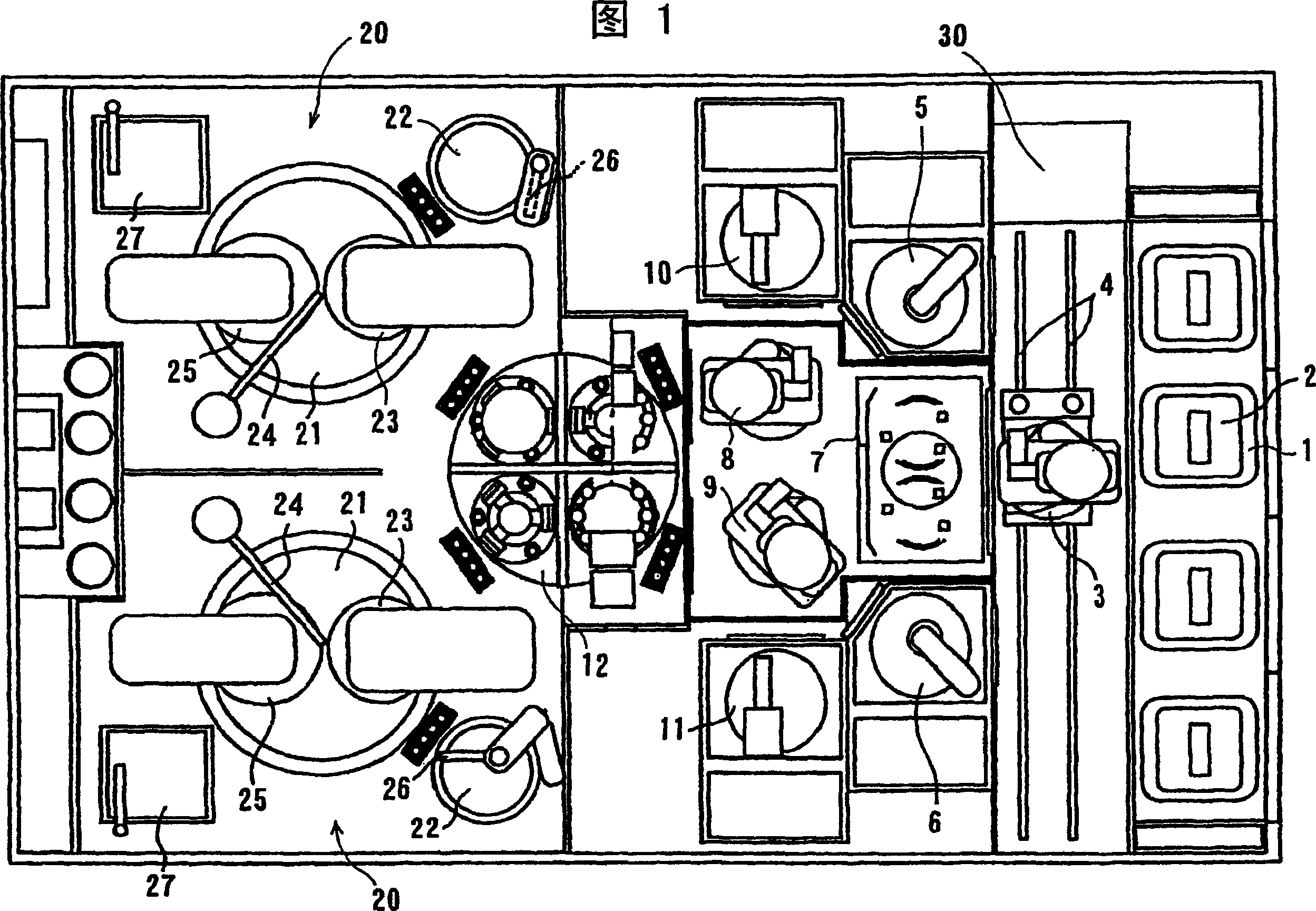

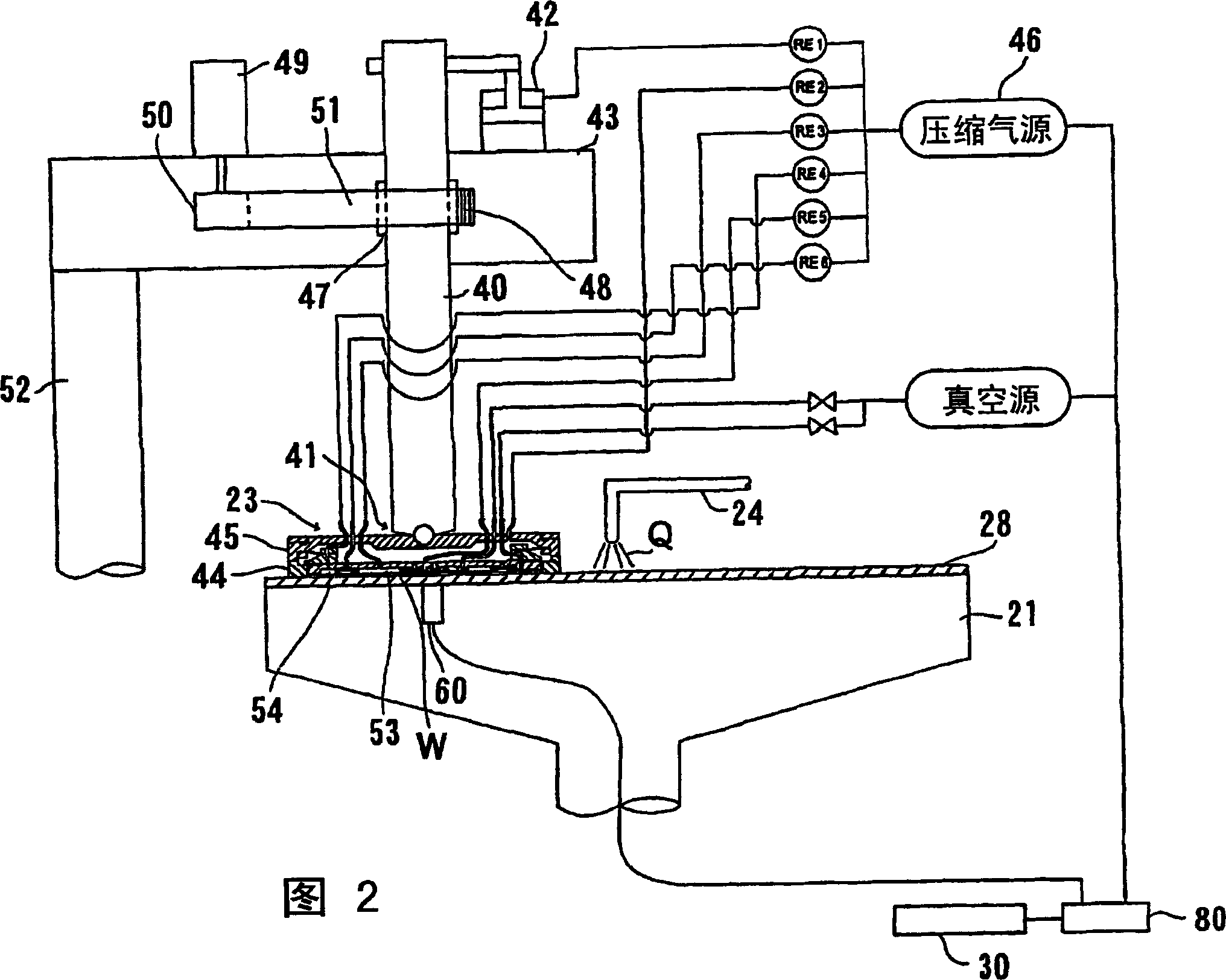

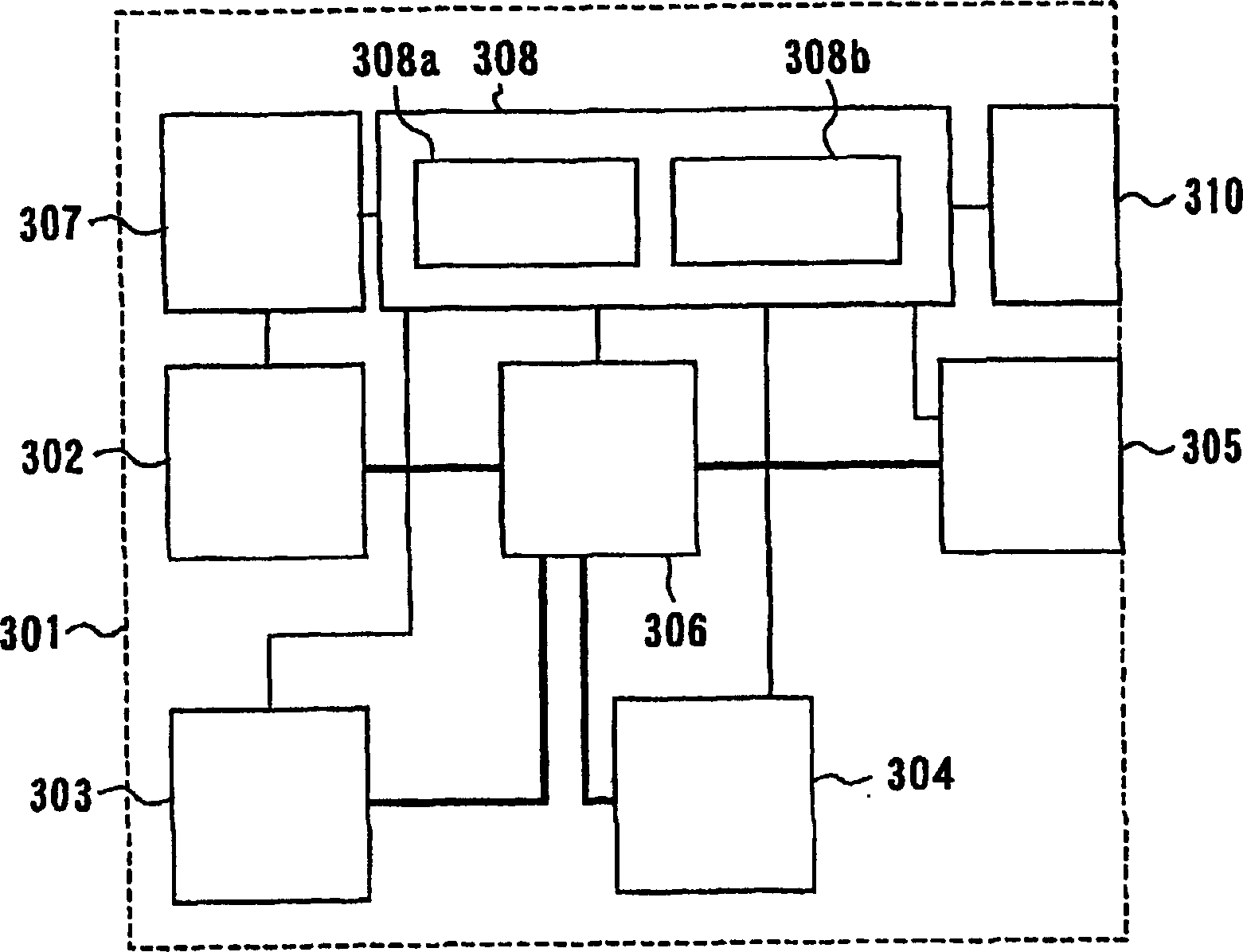

[0048] Reference will now be made to Figures 1 through Figure 13B A polishing apparatus according to an embodiment of the present invention will be described. In the respective drawings, the same or corresponding components are denoted by the same or corresponding reference numerals, and description thereof will not be repeated subsequently.

[0049] FIG. 1 is a plan view showing the overall structure of a polishing apparatus according to a first embodiment of the present invention. As shown in FIG. 1 , the polishing apparatus has four loading / unloading stations 1 each for receiving a cassette 2 containing (or storing) a plurality of substrates such as semiconductor wafers. The polishing device also has a transfer robot (manipulator) 3 which is arranged on a rail 4 so that the transfer robot 3 can move along the rail 4 to reach the corresponding cassette 2 on each loading / unloading station 1 . The polishing device also has two cleaning units 5 and 6 arranged on the opposite...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com