Dynamic regulation method of axial force in multistage centrifugal pump with balance disc to balance axial force

An axial force and balance disc technology, applied in the components of pumping devices for elastic fluids, radial flow pumps, pumps, etc., can solve problems affecting normal production, etc., and achieve reliability index growth and average service life. Extended, well-designed effects

Inactive Publication Date: 2006-08-02

陆雄

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Unplanned downtime occurs frequently, seriously affecting normal production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

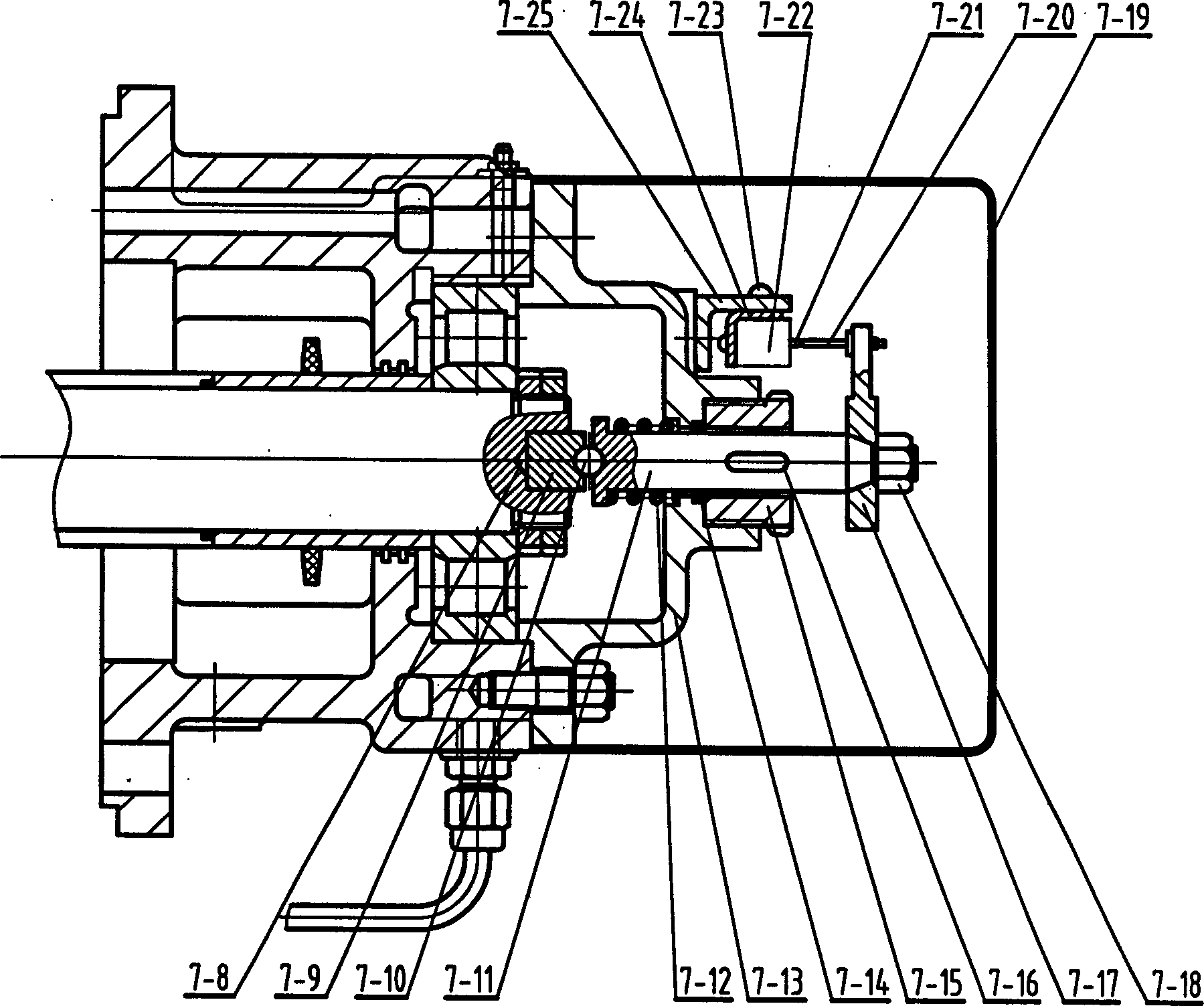

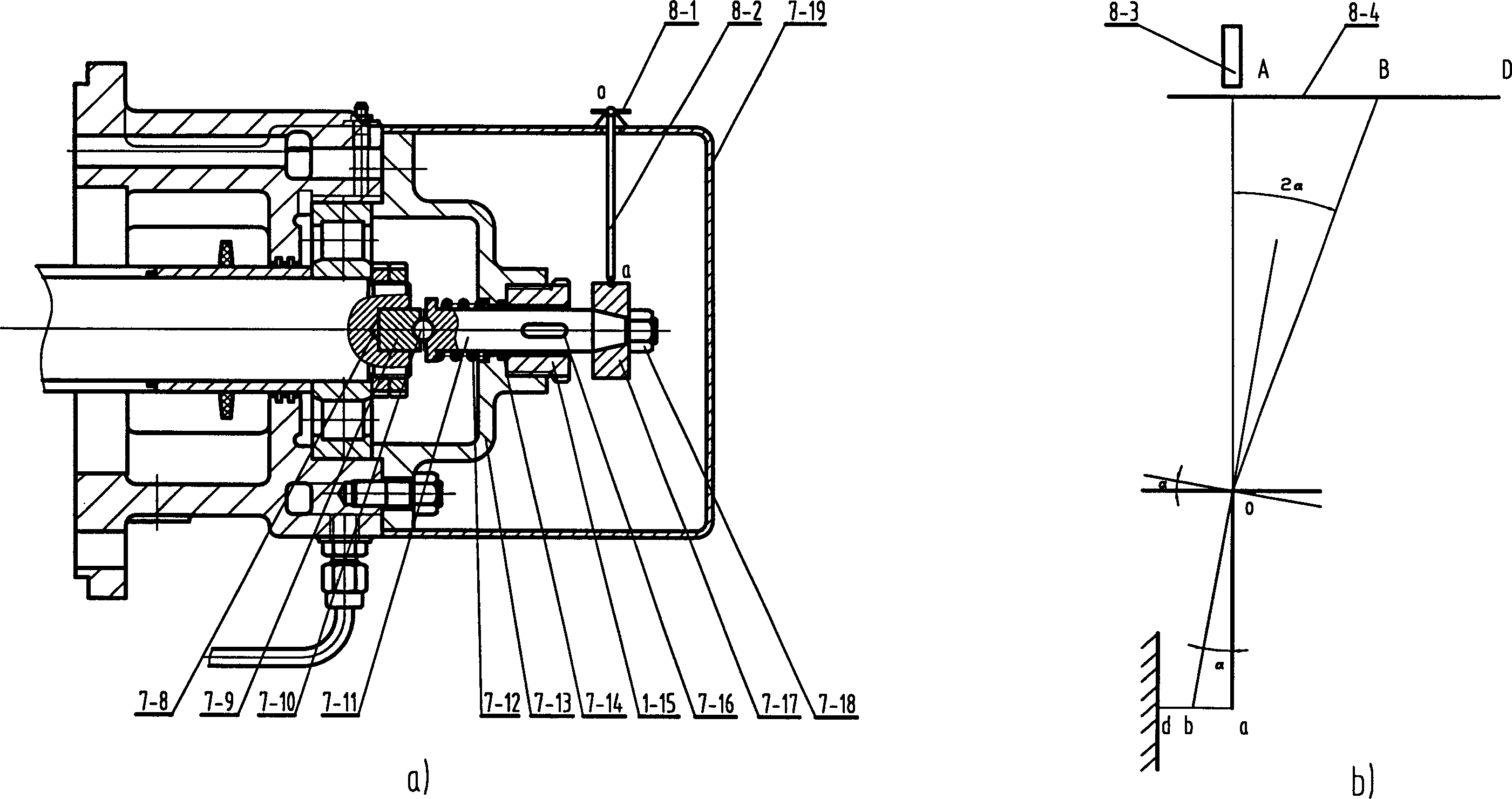

[0043] Regulation device embodiment 2: see Figure 5 , the throttle mechanism 3-1 is a throttle valve or an electric throttle valve. The rest of the structure is the same as the previous example.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to method of regulating the axial force of multi-stage centrifugal pump, and is especially method of regulating multi-stage centrifugal pump with balance disc to balance axial force dynamically and in varying axial force. When some axial force increment from the wear of sealing intervals appears in running multi-stage pump, the flow rate of the throttle mechanism in the regulating device is regulated, so that the pressure inside the balance chamber is lowered, the balance force of the balance disc is increased and the increment in axial force is counteracted timely and properly to prolong the MTBF and the average life of the pump. The present invention has simple structure and reasonable design, and is suitable for various kinds of multi-stage centrifugal pump, volute one and guide vane one, horizontal one and vertical one.

Description

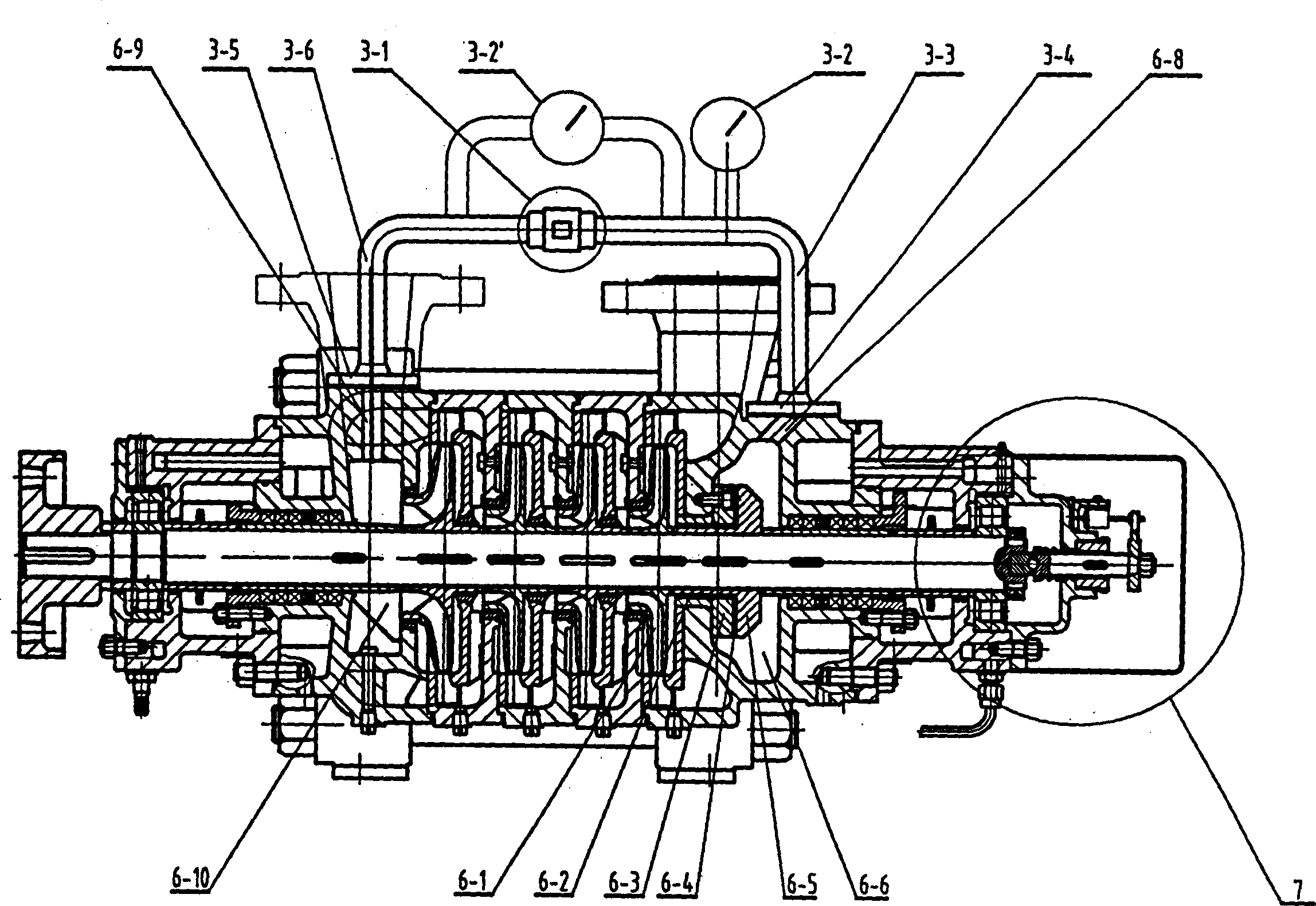

Technical field: [0001] The invention mainly relates to a method for regulating and controlling the variation of the axial force of a multistage centrifugal pump during operation. In particular, the invention relates to a method for adjusting and controlling the axial force of a multistage centrifugal pump in which all impellers are installed in the same direction and the axial force is dynamically balanced by a balance disc during operation. Background technique: [0002] During the operation of the multistage centrifugal pump, the axial force changes with the working conditions. In order to balance the axial force under various working conditions, a large part of multistage centrifugal pumps use a balance plate mechanism. When the balance plate is used to balance the axial force of the multistage centrifugal pump, all the impellers of the multistage pump are installed on the pump shaft in the same direction, and the inlet direction of all impellers points to the suction c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F04D29/66F04D1/08

Inventor 陆雄

Owner 陆雄

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com