Pneumatic tire

A technology for pneumatic tires and tires, which is applied to the reinforcement layer of pneumatic tires, special tires, tire parts, etc., can solve the problems of insufficient transmission, increased rolling resistance, and inability to fully improve the lateral spring constant and circumferential spring constant, etc. Achieve the effect of increasing lateral spring constant and circumferential spring constant, reducing rolling resistance and longitudinal spring constant, and improving handling stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

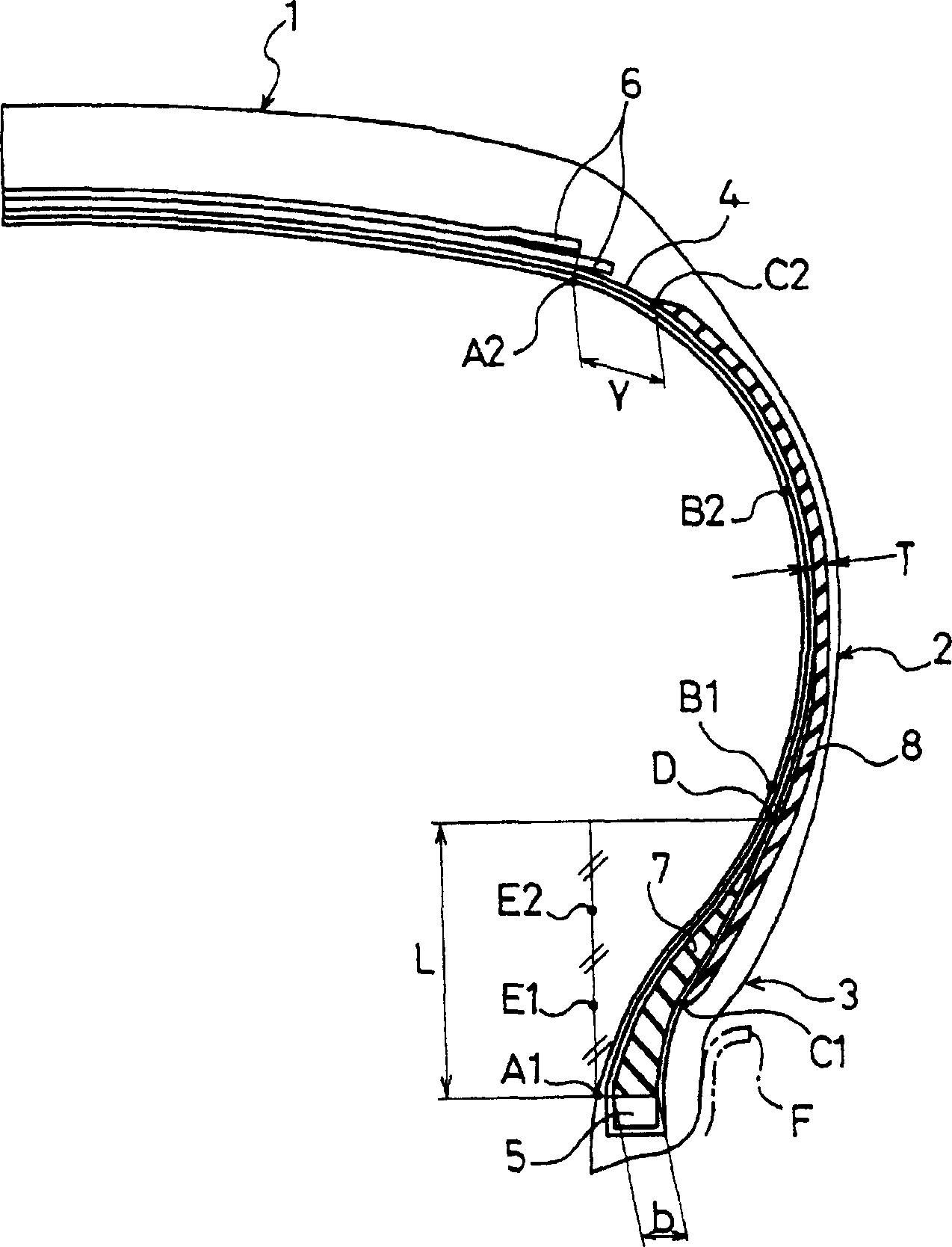

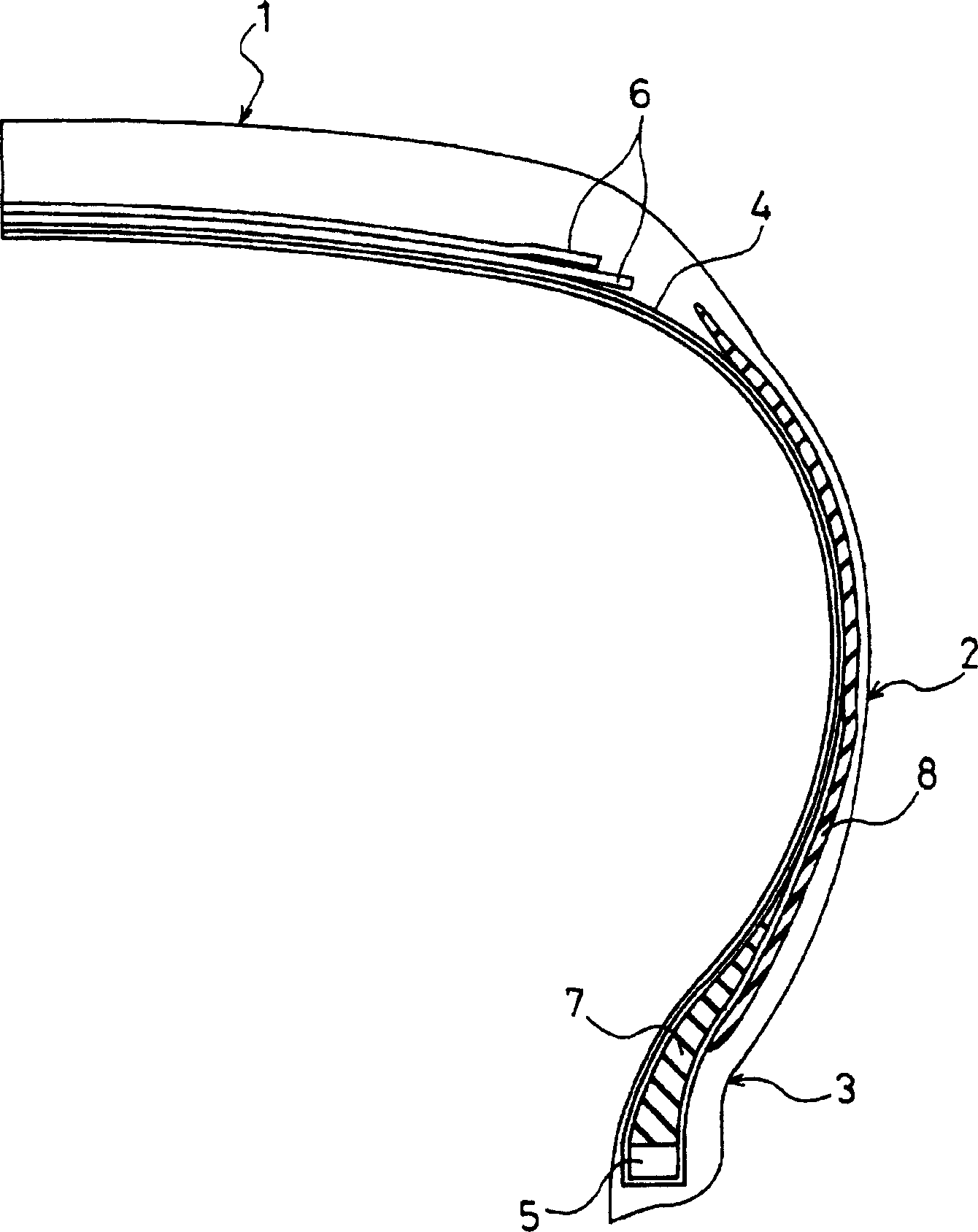

[0054] In a pneumatic tire of tire size 205 / 65R15, conventional examples, Examples 1 to 7, and Comparative Examples 1 to 1 were produced in which only the reinforcing structures of the tire side portion and the bead portion were different as shown in Tables 1 and 2. 10.

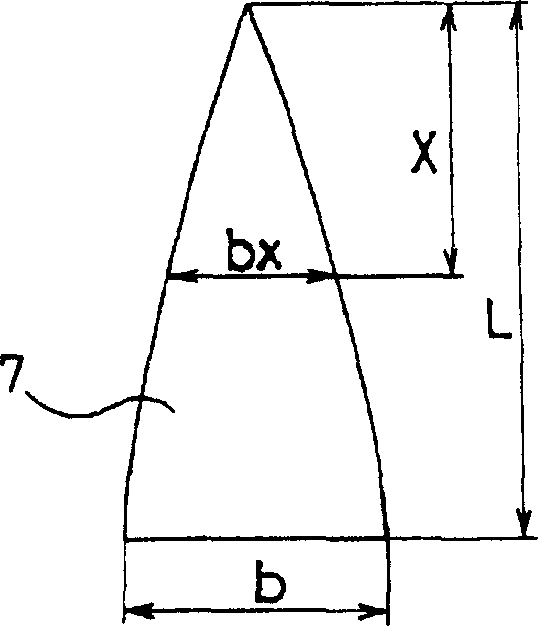

[0055] Here, in all the tires, the JIS-A hardness of the carcass rubber is set to 64, the JIS-A hardness of the tire side rubber is set to 65, and the height of point B1 (height from the upper end of the bead core) is set to is 43mm, the height of the rim bead (the height from the upper end of the bead core) is set to 15mm, the width b of the filler on the bottom edge of the bead filler is set to 8mm, and the JIS-A hardness of the bead filler is set to is 92.

[0056] For these test tires, road noise, ride comfort, handling stability, and rolling resistance were evaluated by the following methods, and the results are shown in Tables 1 and 2 together.

[0057] Road Noise:

[0058] Each experimental tire was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com