CO2 corrosion-prevented cement system for oil well

A technology of carbon dioxide and cement, which is applied in the field of cement system, can solve the problems of less research on corroded cement sheath, shorten the production life of oil and gas wells, and not pay enough attention to it, and achieve the effects of enhanced compactness, high corrosion resistance, and slowed down corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

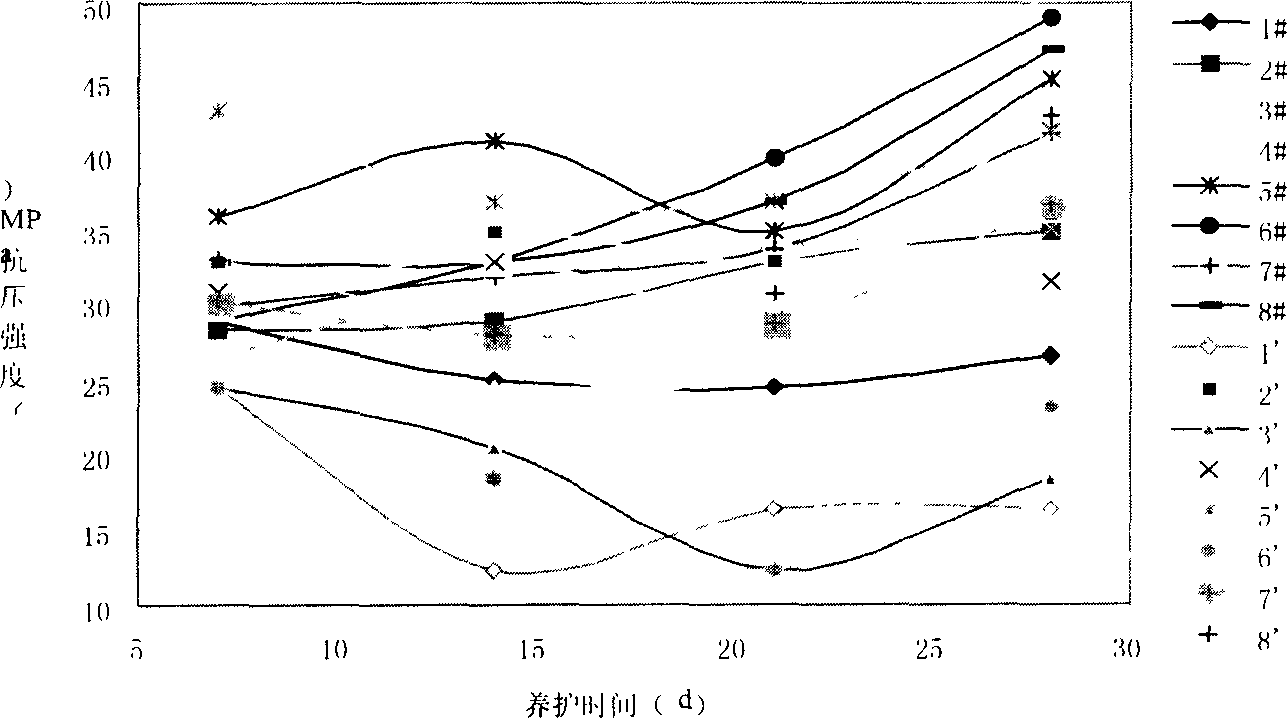

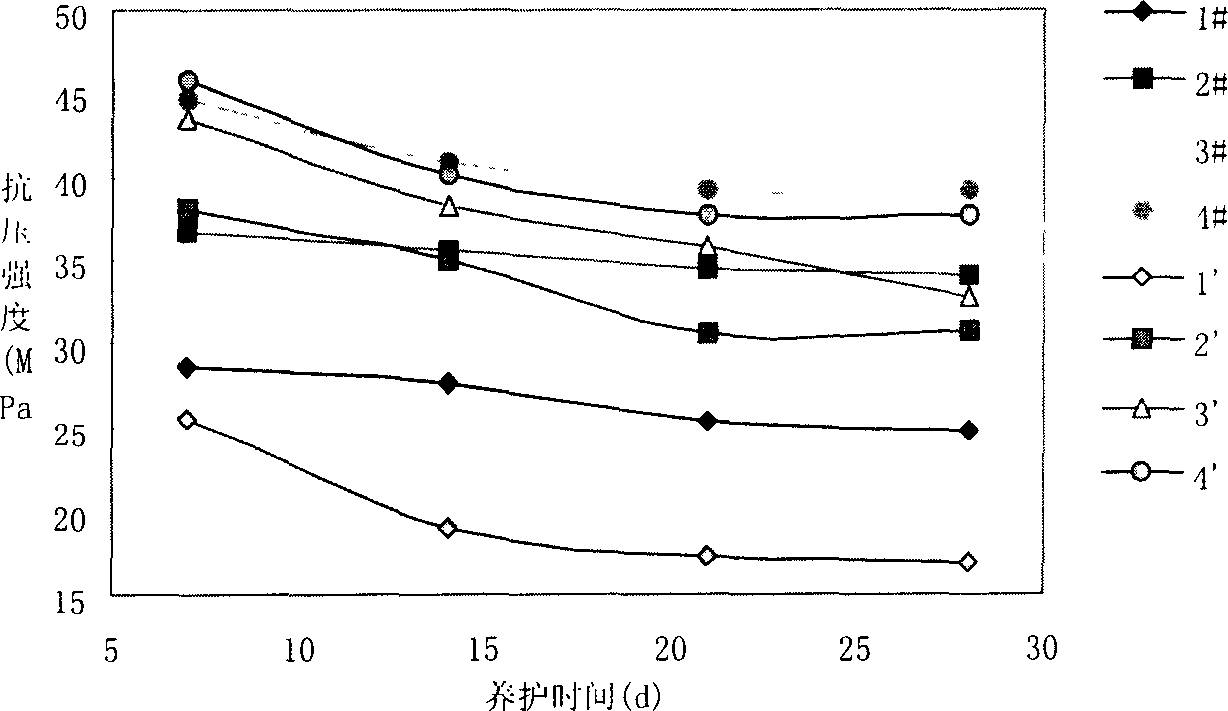

[0037] Further description will be given below in conjunction with specific examples. The cement system for preventing carbon dioxide corrosion for oil wells includes the following components: the following components are proportioned by mass percentage based on the total weight of cement: 8-35% silica sand or quartz Sand, 3-5% silica, 6.5-18% fluid loss reducer DSJ, DSHJ or DHL, cement. Wherein DSJ is made of 75% N,N-dimethylacrylamide, 5% sodium propylene sulfonate, 20% N-vinylpyrrolidone; DHL is the fluid loss reducer described in the application document No. 03101262.0 (the molecular weight of styrene-butadiene latex is 5000-50000, styrene-butadiene latex is a random polymerization of styrene and butadiene, and the values of x, y and z are 1000-1500); DSHJ is in the application document with application number 02157940.7 The fluid loss reducer and microsilica are represented by DCR.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com