Electric dust collector

A vacuum cleaner and electric technology, applied in vacuum cleaners, cleaning equipment, household appliances, etc., can solve the problems of short contact time, small reduction of odor, poor dust removal efficiency, etc., and achieve the effect of simple mechanism, small body, and odor reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

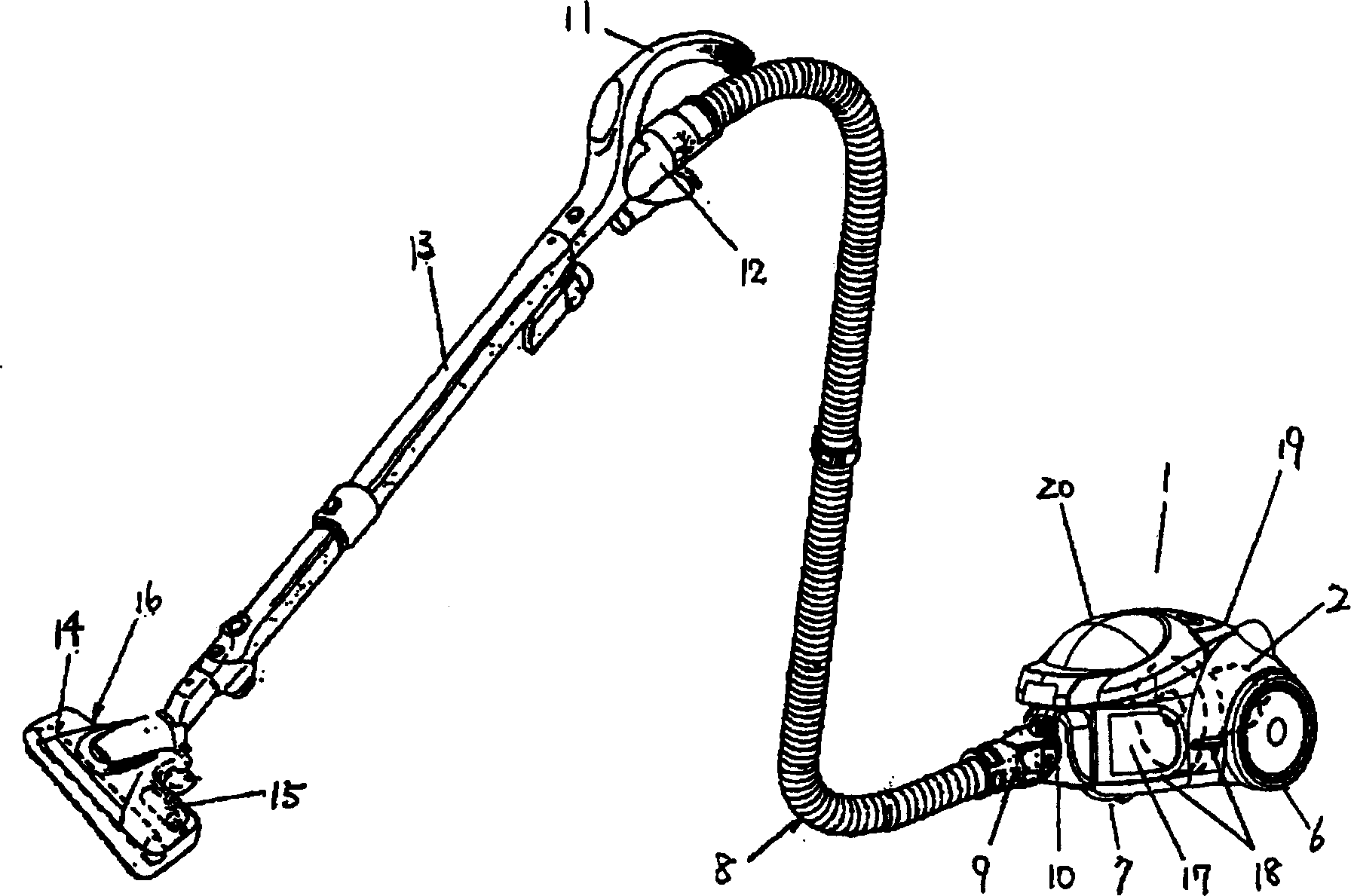

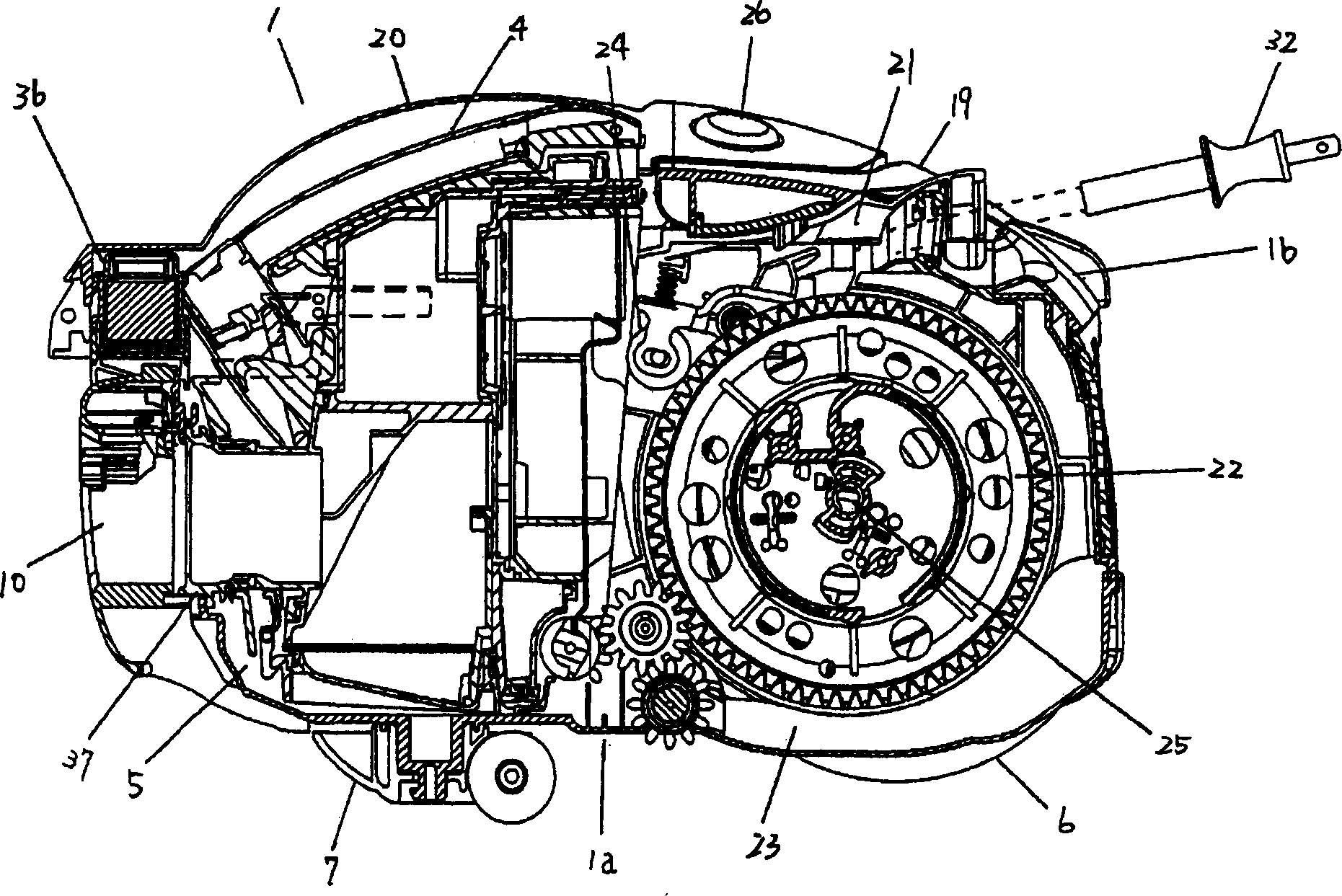

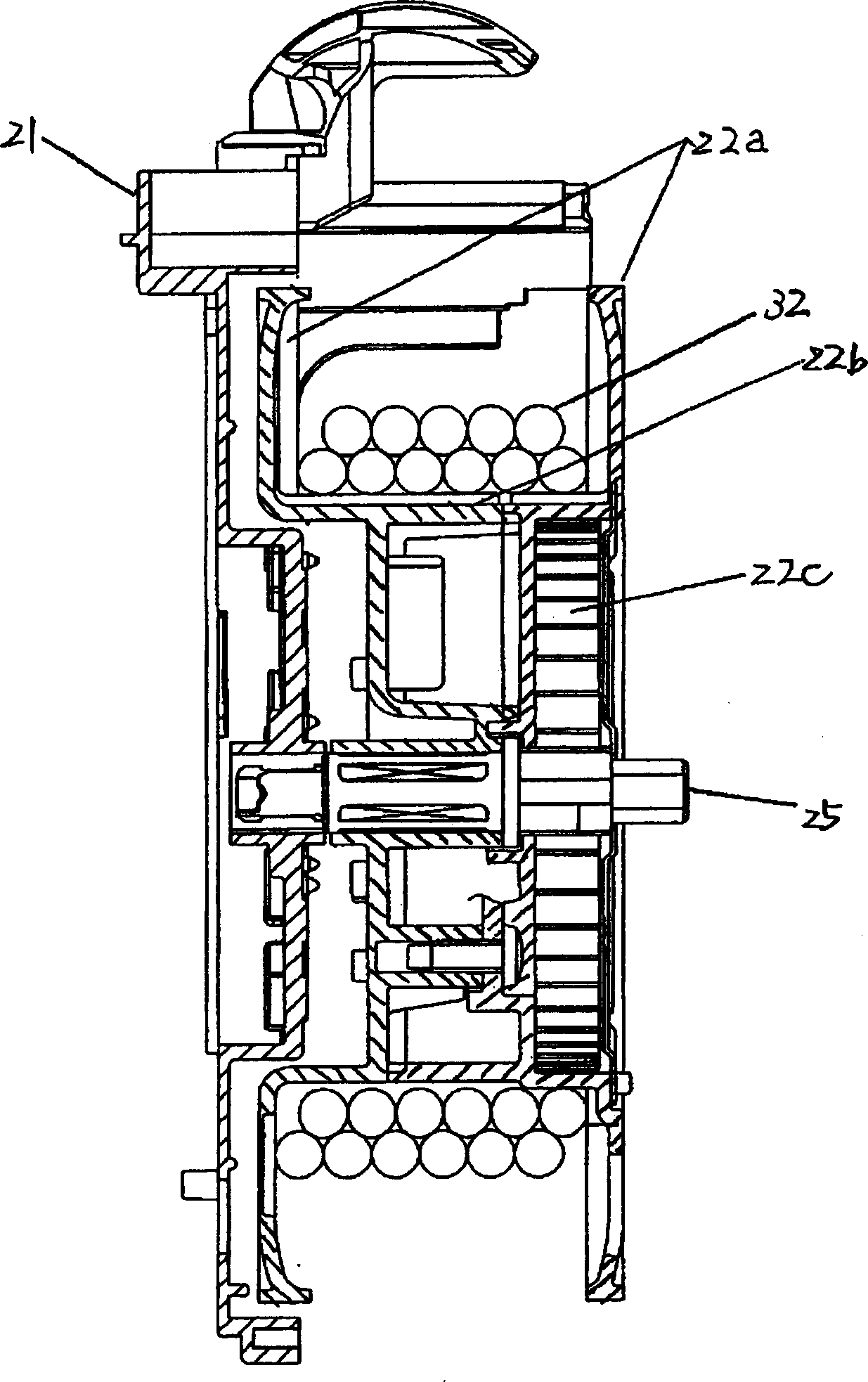

[0034] pass below Figure 1-12 The electric vacuum cleaner in the first embodiment of the present invention will be described.

[0035] figure 1 It is an overall oblique view of the electric vacuum cleaner in this embodiment, figure 2 It is a sectional view of the electric vacuum cleaner.

[0036] figure 1 Among them, 1 is the main body of the vacuum cleaner. The rear part of the main body of the vacuum cleaner 1 is provided with an electric fan chamber 3 with a built-in electric fan 2, and the front part is provided with a dust box storage room 5. The dust box storage room 5 is equipped with a detachable . A dust box unit 4 for separating / capturing dust. In addition, a pair of freely rotatable walking wheels 6 are arranged on both sides of the rear and lower sides of the body 1, and rollers 7 that are also used for walking are arranged on the front bottom surface. The front part of the vacuum cleaner main body 1 is provided with an air inlet 10 , and a connecting pipe 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com