Pipe pulse stream generator

A pulse flow generator and generator technology, applied in the direction of fluid flow, mechanical equipment, etc., can solve the problems of high energy consumption and large resistance loss, and achieve the effect of improving thermal efficiency, improving thermal efficiency, and reducing resistance loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

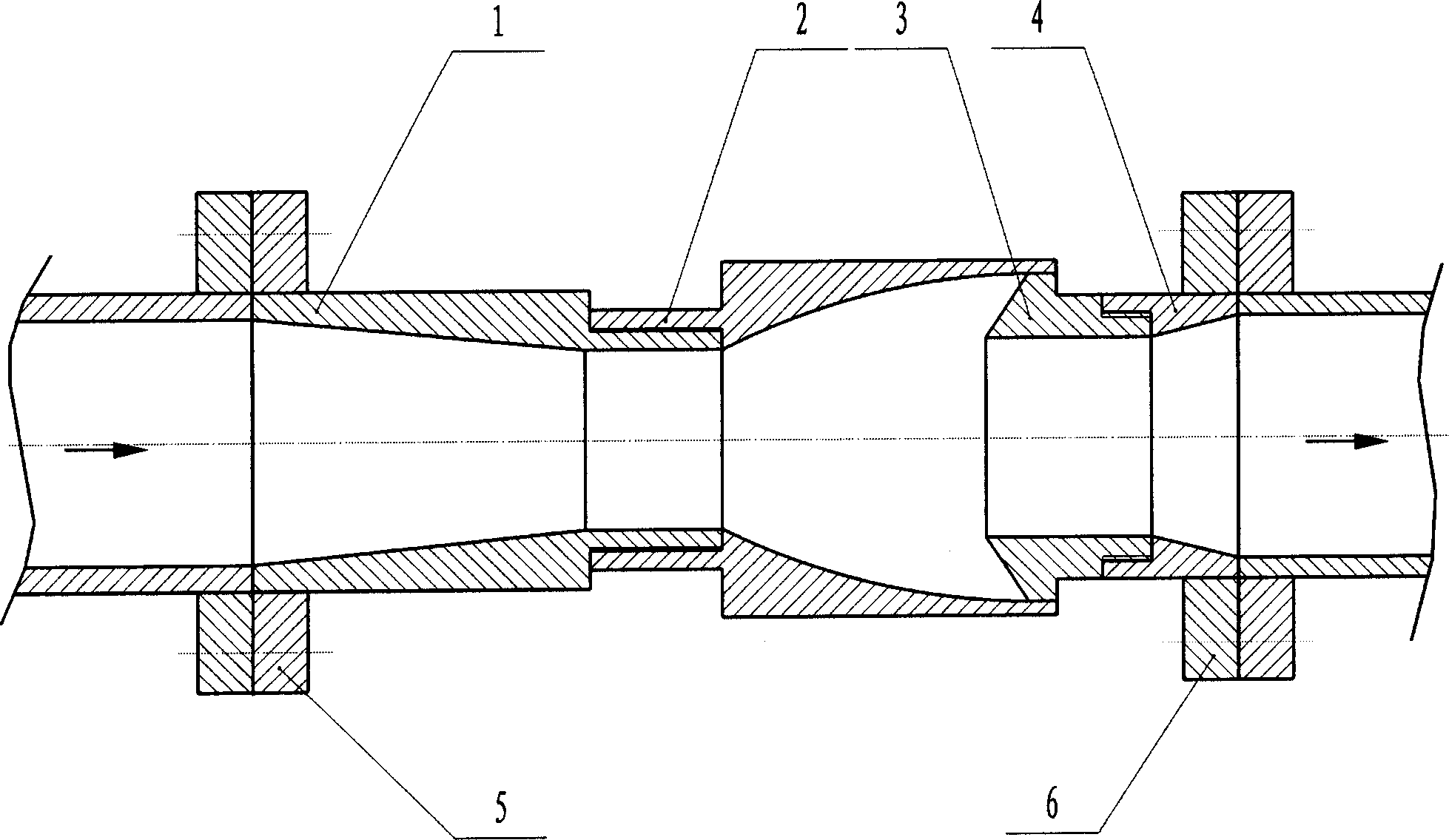

[0016] The upper nozzle body 1, the self-excited oscillation cavity 2, the lower nozzle body 3 and the short pipe 4 are sequentially installed on the same axis. The upper nozzle body 1 has a cone angle of 13°, a conical hole whose length is 7 times the outlet diameter of the upper nozzle body 1, and a through hole whose length is equal to the round hole of the outlet diameter of the upper nozzle body 1. The lower nozzle body 3 The cone angle of the frustum of the front end is 110°, and the outlet hole end of the lower nozzle 3 is equipped with a through-hole pipe 4 with an inner cone angle of 25°.

[0017] The upper nozzle body 1 and the input pipeline are sealed and fixedly connected through the flange plate 5, and the connection mode between the upper nozzle body 1 and the self-excited oscillation cavity 2 is threaded connection or flange plate sealed and fixed connection. The opening end of the self-excited oscillation cavity 2 is fixedly connected with the lower nozzle bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com