Stripped gas method for recovering C2 and higher carbon content hydrocarbon constituent

A dry gas and hydrocarbon technology, which is applied in the recovery of liquid hydrocarbon mixtures and the petroleum industry, can solve problems such as limited application range, investment, high operating cost, and difficult operation, and achieve practical operability and solve technical problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This embodiment reclaims C from refinery catalytic cracking dry gas 2 and C 2 The method of the above hydrocarbon components, catalytic cracking dry gas treatment capacity 5000Nm 3 / h, pressure 0.55MPa, temperature 40°C, its gas composition is shown in Table 1:

[0027] composition

H 2

O 2

N 2

CH 4

CO

CO 2

C 2 h 4

C 2 h 6

C 3 h 6

C 3 h 8

C 4

C 5 +

h 2 S

Content %

25.8

0.3

9.1

30

0.9

1.5

13.5

12

4.2

0.8

0.8

1.1

50ppm

[0028] C in the table 4 Indicates hydrocarbon gases containing 4 carbon atoms, such as n-butane, isobutane, isobutene, n-butene, anti-butene; C 5 + Indicates hydrocarbon gases containing 5 and more carbon atoms.

[0029] In this embodiment, firstly, the pressure swing adsorption method is used to concentrate and separate the C in the catalytic cracking dry gas. 2 ...

Embodiment 2

[0045] Coking dry gas flow rate is 12000Nm 3 / h, pressure 0.7Mpa, temperature 30°C, its component content is shown in Table 4, and enters the pressure swing adsorption gas separation unit, MEA desulfurization and decarbonation unit, water washing and dehydration unit, water separation unit, fine dehydration unit, dehydration unit, Coking dry gas separation, purification and recovery C composed of arsenic unit, fine desulfurization unit and hydrodeoxygenation reactor unit 2 and C 2 The above hydrocarbon component device.

[0046] composition

H 2

O 2

N 2

CH 4

C 2 h 4

C 2 h 6

C 3 h 8

C 3 h 6

i-C 4

n-C 4

n-C 4 =

h 2 S

As

Content %

4.90

0.64

3.24

52.97

3.32

19.21

9.21

5.03

0.54

0.47

0.46

0.01

0.5ppm

[0047] Table i-C 4 , n-C 4 , n-C 4 = Respectively represent isobutane, n-butane and n-buten...

Embodiment 3

[0064] Refinery catalytic cracking dry gas flow rate 25000Nm 3 / h, pressure 0.60MPa, temperature 30°C, its gas composition is shown in Table 7:

[0065] composition

H 2

O 2

N 2

CH 4

CO

CO 2

C 2 h 4

C 2 h 6

C 3 h 6

C 3 h 8

C 4

C 5 +

h 2 S

As

h 2 o

Content %

25.3

0.3

9.1

30

0.9

1.5

13.5

12

4.2

0.8

0.8

1.1

30ppm

2ppm

0.5

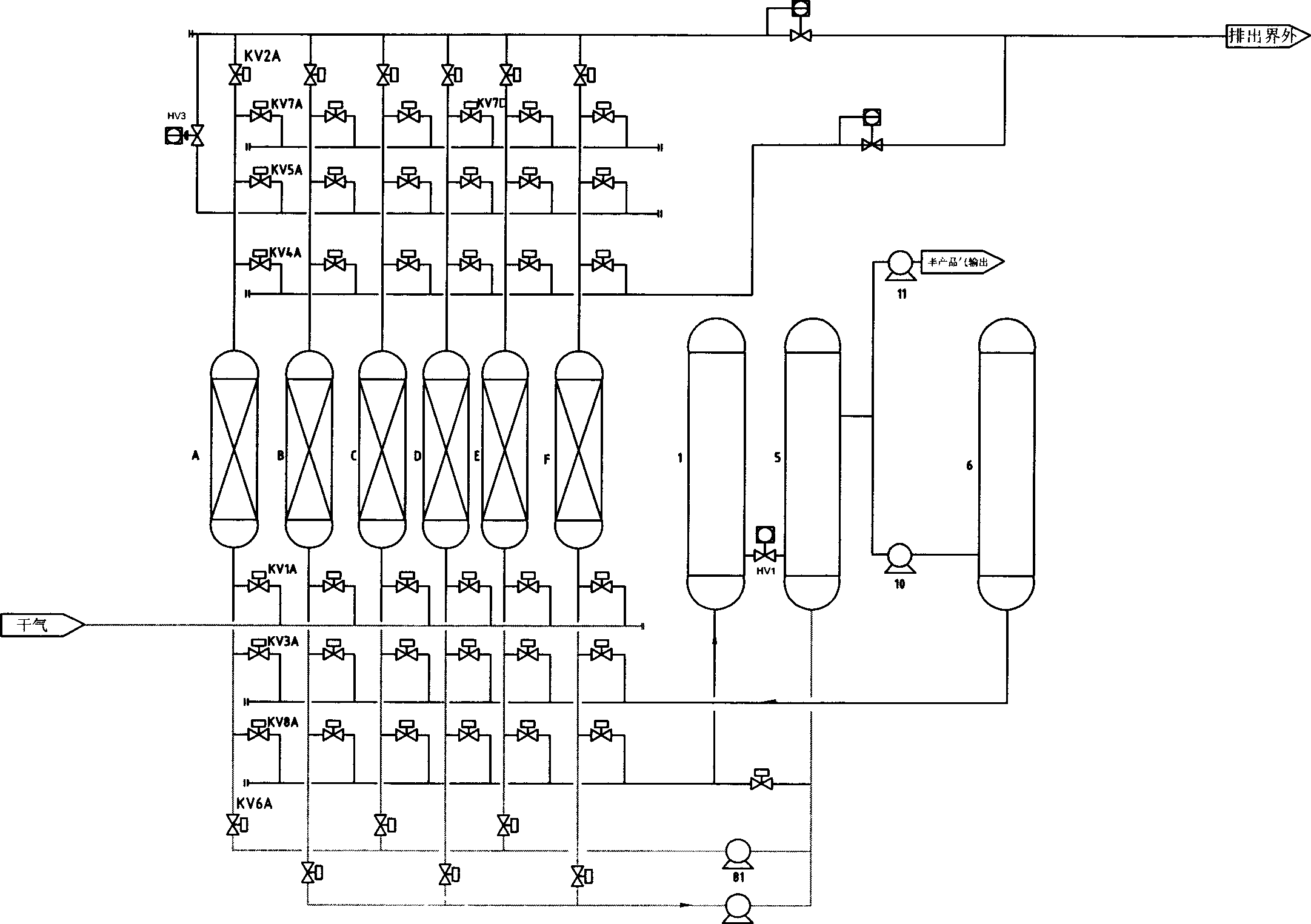

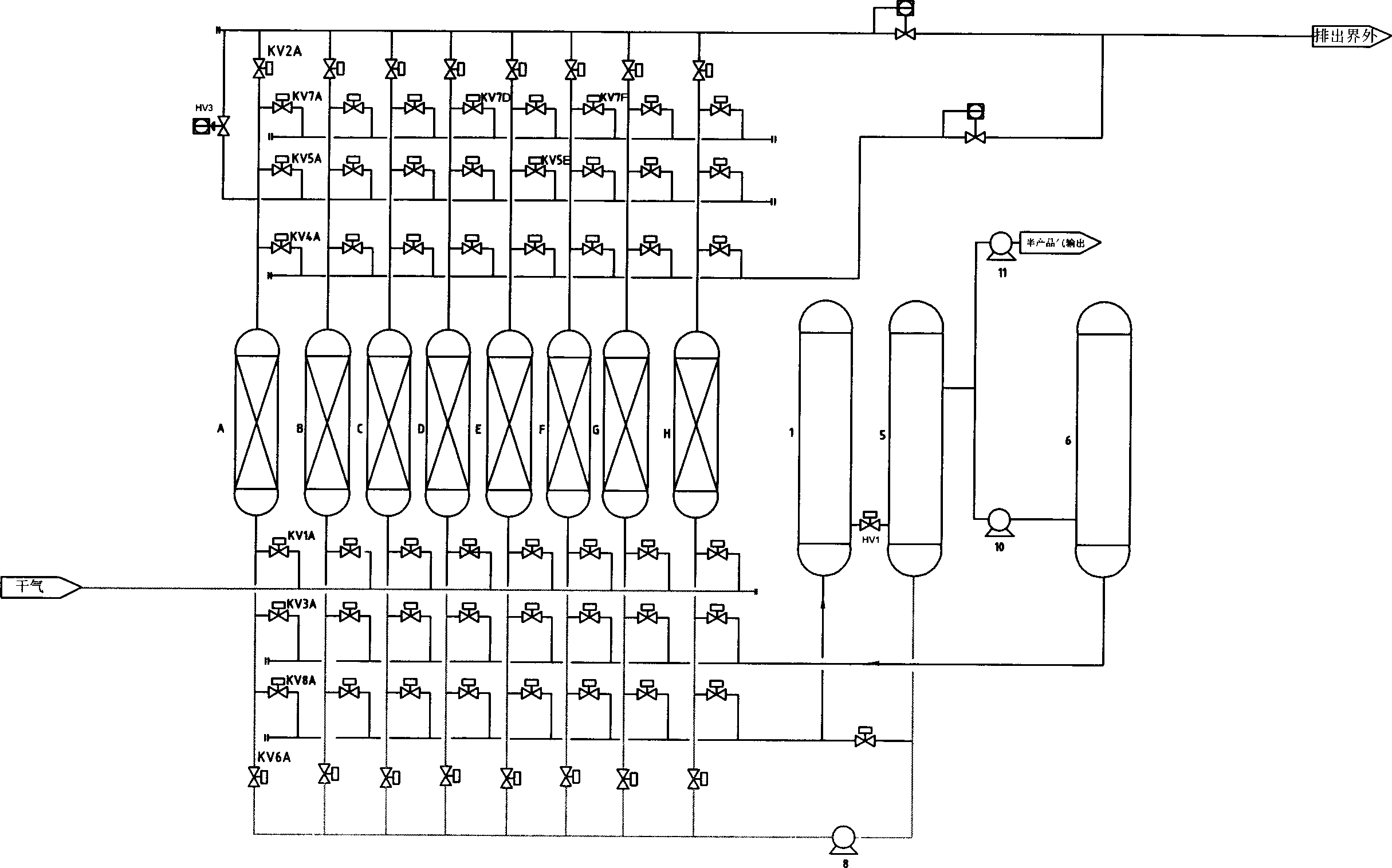

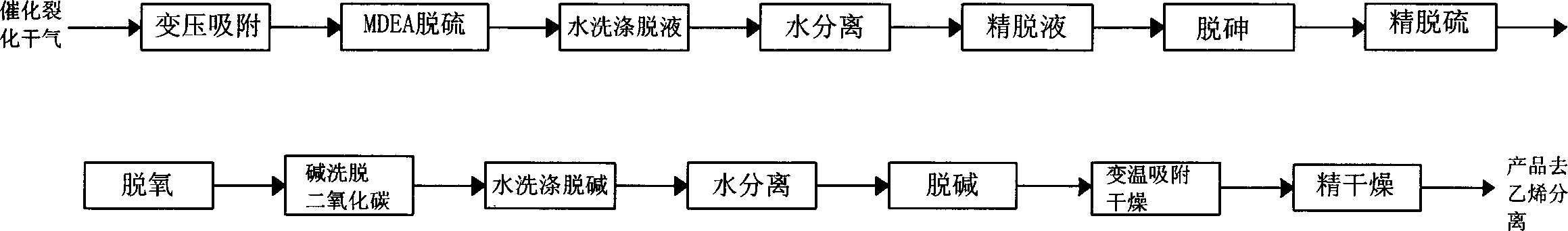

[0066] The catalytic cracking dry gas separation and purification device in this embodiment is as follows image 3 As shown, it consists of pressure swing adsorption unit, MDEA desulfurization and decarbonation unit, water washing and dehydration unit, water separation unit, fine dehydration unit, arsenic removal unit, fine desulfurization unit, hydrodeoxygenation reactor unit, alkali elution carbon dioxide unit 1. Water washing dealkalization unit, wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com