Machine-engraving stone-made cinerary casket forming method

A technique of urn and forming method, which is applied in the direction of urn, engraving, processing models, etc., which can solve the problems of difficult long-term preservation and perishability, and achieve the effects of ensuring consistency, reducing production cost and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

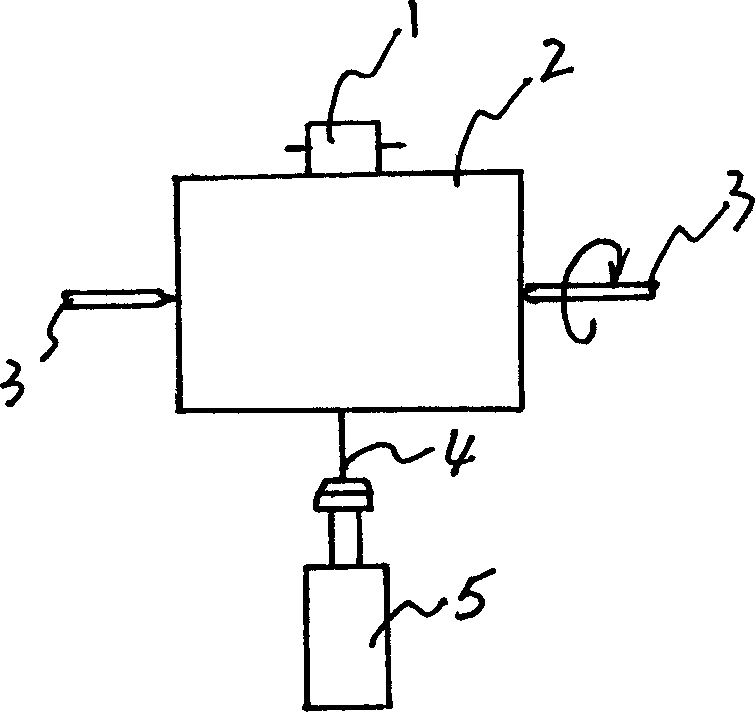

[0012] Embodiment 1: with reference to attached figure 1 . Machine-carved stone urn molding method, ① process the urn body 2 or the lid (stone urn blank, including base, bottom plate, or without base, bottom plate), ② put the urn body or urn cover Both sides are positioned by the top cone 3 and the urn body or urn cover can rotate around the top cone. A manipulator 1 is arranged between the two top cones. The manipulator can be a rubber roller or a metal roller or a rubber wheel or a metal wheel, etc. The mechanism drives it to rotate or not to move or to rotate synchronously with the engraving head 5 of the engraving machine. The formation of the driving mechanism is a prior art, so it will not be described here. The manipulator is used to control the rotation and positioning of the urn body or the lid and control the work of the drive mechanism according to the engraving (pattern, text) program (control) of the engraving machine. The drive mechanism is used to control the m...

Embodiment 2

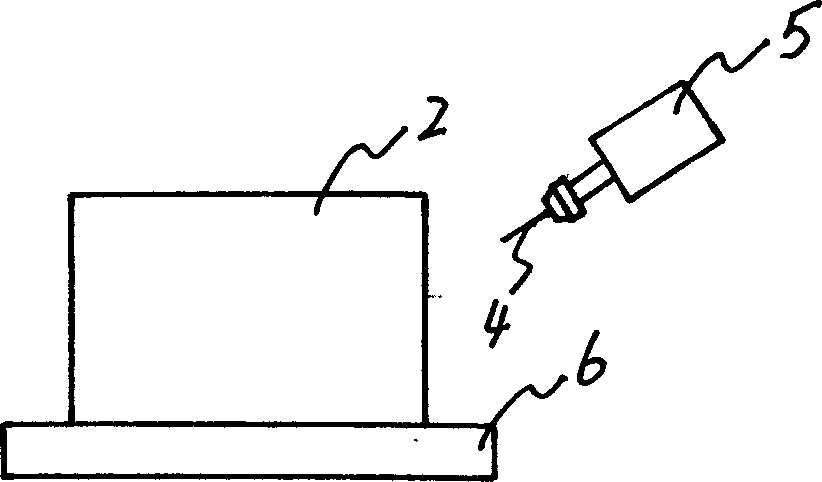

[0013] Embodiment 2: with reference to attached figure 2 . Machine-carved stone urn molding method, ① process and shape the stone urn body 2 or stone box cover (stone urn blank, including base, bottom plate, or without base, bottom plate), ② stone urn One side of the box body or the stone urn cover is fixed on the engraving seat 6 of the engraving machine (the fixing method can be the suction cup fixing method, the double-sided bonding method, or the top-fixing method) and the engraving seat does not move, ③ The engraving head 5 of the engraving machine is a universal rotating structure (the formation of this universal structure is a prior art, which is not described here), but it is controlled by a drive mechanism controlled by a computer and a software program, and can be controlled by the drive mechanism according to the engraving machine. The pre-set program automatically engraves continuously around the face and corner of the stone urn body or stone urn cover on the car...

Embodiment 3

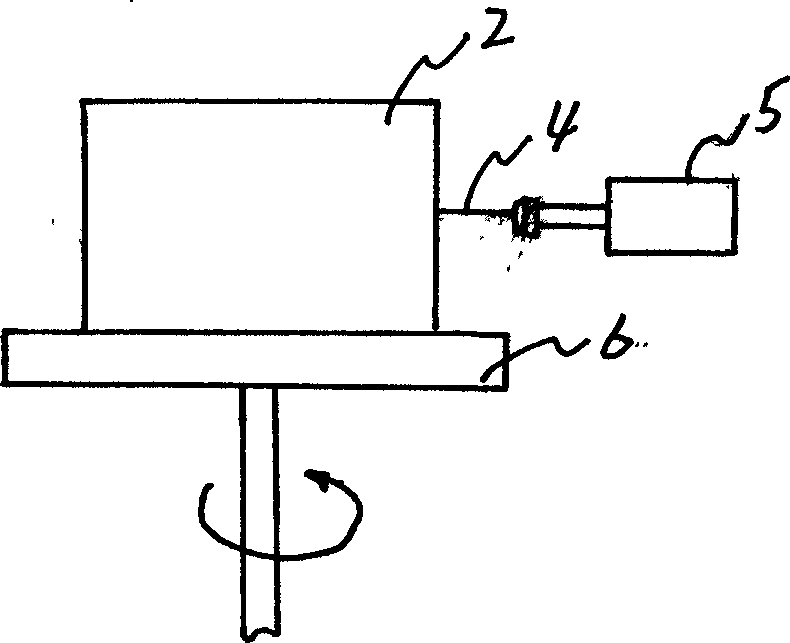

[0014] Embodiment 3: with reference to attached image 3 . Machine-carved stone urn molding method, ① process and shape the stone urn body 2 or stone box cover (stone urn blank, including base, bottom plate, or without base, bottom plate), ② stone urn One side of the box body or the stone urn cover is fixed on the engraving seat 6 of the engraving machine (the fixing method can be a suction cup fixing method, or double-sided bonding, or top-fixing method) and the engraving seat can be fixed according to the engraving machine in advance. The set program can rotate synchronously with the engraving head 5 according to the engraving speed of the engraving machine, engraving, ..., continuous engraving without discontinuity in the middle, until the engraving pattern is completed. The corner surface of the stone urn body or the stone urn cover is an arc or an inclined surface; the stone urn body includes a stone box body frame and a stone base or a stone bottom plate. When the ston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com