Method for preparing bacillus thuringiensis microbiological pesticide by starch waste liquor

A microbial insecticide, the technology of Bacillus thuringiensis, is applied in the field of production of Bacillus thuringiensis microbial insecticides, which can solve the problems of not yet seen Bacillus thuringiensis microbial insecticides, limited application scope, and high nucleic acid content, and achieves expansion of resource utilization. Ways, promotion and application, high value-added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

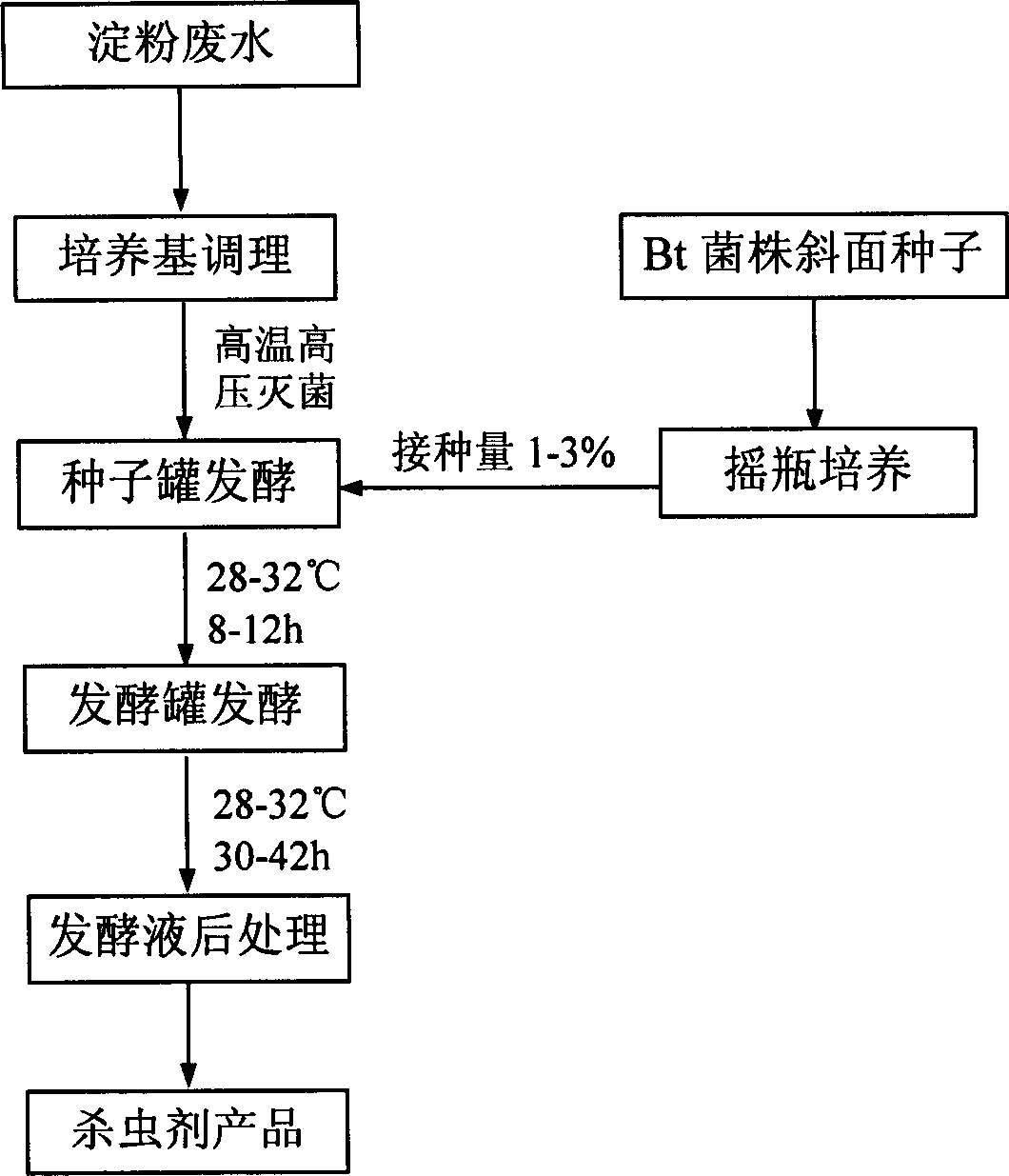

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 produces water suspension concentrate:

[0029] (1) Starch wastewater sample

[0030]The starch wastewater from a starch factory in Shijiazhuang City, Hebei Province is taken. The factory uses sweet potatoes as raw materials to produce starch. The processing process is: sweet potatoes→washing→grinding→sieving→slurry→centrifugal separation→starch washing→dehydration→drying→starch. The main sources of wastewater are washing water and separation wastewater (potato pulp wastewater and protein water). After analysis, the carbohydrate content in the waste water was 13.2g / L, the crude protein content was 6.1g / L, and the pH=4.45.

[0031] (2) Medium conditioning

[0032] Adjust the solid content of starch wastewater to 3.5%, add 0.5g / L of dipotassium hydrogen phosphate mineral salt, 0.2g / L of magnesium sulfate, 0.02g / L of manganese sulfate and 2.0g / L of defoaming agent foam enemy. Use NaOH to adjust the pH to 9.7-9.8, sterilize in the seed tank and fermenter at ...

Embodiment 2

[0044] Example 2 Production of wettable powder

[0045] (1) Starch wastewater sample

[0046] With embodiment 1.

[0047] (2) Medium conditioning

[0048] With embodiment 1.

[0049] (3) Shake flask culture

[0050] With embodiment 1.

[0051] (4) Seed tank fermentation

[0052] Inoculate 2% of the above-mentioned shake flask bacterial liquid, and ferment and cultivate. The culture conditions are: tank temperature 28° C., tank pressure 0.03 MPa, ventilation rate 1:1.0 (V / V / min), stirring speed 240 rpm, and fermentation time 12 hours.

[0053] (5) Fermentation tank fermentation

[0054] Inoculate the fermenter with 8% seed solution. The culture conditions are: tank temperature 28° C., tank pressure 0.03 MPa, ventilation rate 1:1.2 (V / V / min), stirring speed 200 rpm, and fermentation time 36 hours.

[0055] (6) post-treatment of fermentation broth

[0056] After the fermentation is finished, concentrate 5 times by high-speed centrifugation, add 40g / L dispersant kaolin a...

Embodiment 3

[0059] Example 3 Production of wettable powder

[0060] (1) Starch wastewater sample

[0061] Take starch wastewater from a starch factory in Beijing. The factory uses jade as raw material for raw starch. The processing process is: corn→sieving→soaking→crushing→germ separation→grinding→sieving→precipitation separation→starch washing→dehydration→ Dry → starch. The main sources of wastewater are soaking water and yellow slurry water. After analysis, the carbohydrate content in the starch wastewater was 6.8g / L, the crude protein content was 19.0g / L, and the pH=4.80.

[0062] (2) Medium conditioning

[0063] Adjust the solid content of starch wastewater to 5.0%, add 0.75g / L dipotassium hydrogen phosphate, 0.3g / L magnesium sulfate, 0.03g / L manganese sulfate and 2.5g / L foam enemy. Adjust the pH to 9.5 with KOH, sterilize in the seed tank and fermenter at 15 lb pressure and 121°C for 60 minutes, cool to 35°C for later use, and the pH after sterilization is about 7.0-8.0.

[0064...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com