Flexible bimetallic tube

A double-layer pipe and double-layer technology, applied in the direction of hoses, pipes, pipes/pipe joints/pipe fittings, etc., can solve the problem of damage to the air-tightness or liquid-tightness of the flow path, weak joint strength at the joint, and easy peeling, etc. problems, to achieve the effect of small pressure loss, excellent flexibility, and improved flat strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

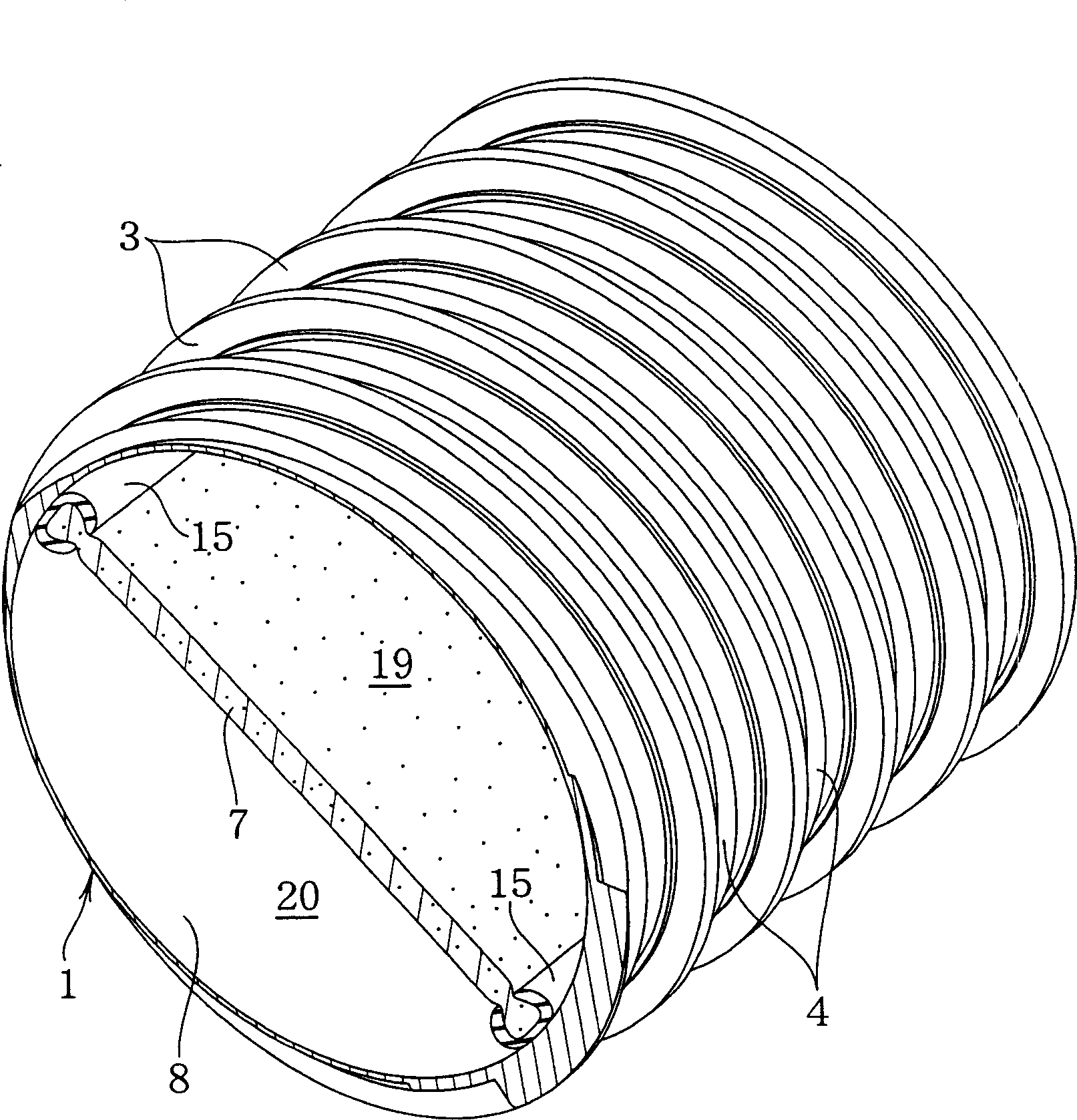

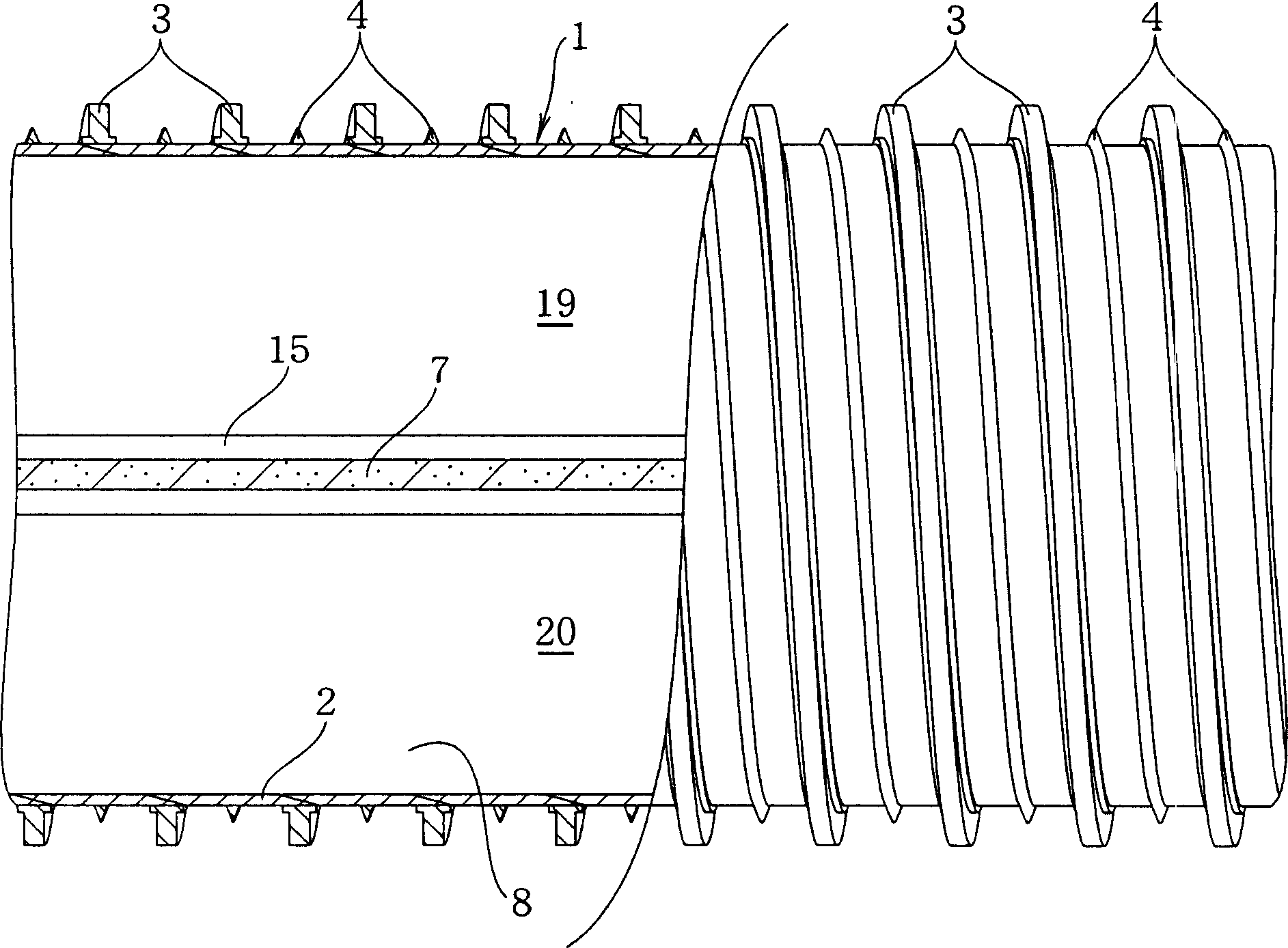

[0029] The flexible double-layer pipe according to one embodiment of the present invention is connected to, for example, a ventilation device installed in a house, and used as an intake and exhaust pipe.

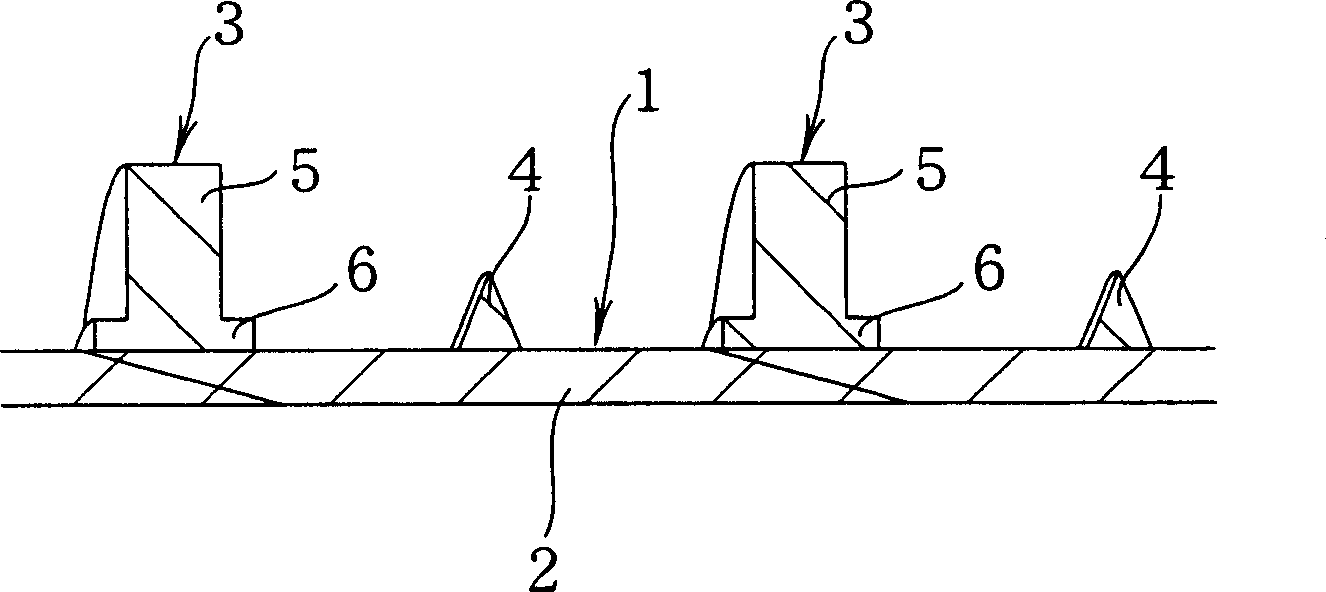

[0030] In the figure, 1 is a pipe main body of a flexible double-layer pipe, and the pipe main body 1 is formed by spirally winding a resin band-shaped body 2 composed of a polyolefin-based elastic resin. In other words, the resin strip 2 is wound spirally, and the edge portions along the longitudinal direction of the leading resin strip 2 and the subsequent resin strip 2 are separated from each other by a distance between the pipe diameters. In the state where the directions are overlapped, thermal bonding or adhesive bonding is performed, whereby the pipe body 1 having a thinner and thicker pipe wall with a cross-sectional circular shape is formed. In addition, the pipe main body 1 is not limited to the case where such a resin-made strip-shaped body is wound spirally, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com