Method for manufacturing transparent anode and electrode lead wire of organic luminescent display unit

A light-emitting display device and electrode extraction technology, applied in the direction of electroluminescent light source, light source, electric light source, etc., can solve the problems of reducing device yield, affecting device luminous brightness, and luminous efficiency. Possibility of impurity contamination, effect of improving performance and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

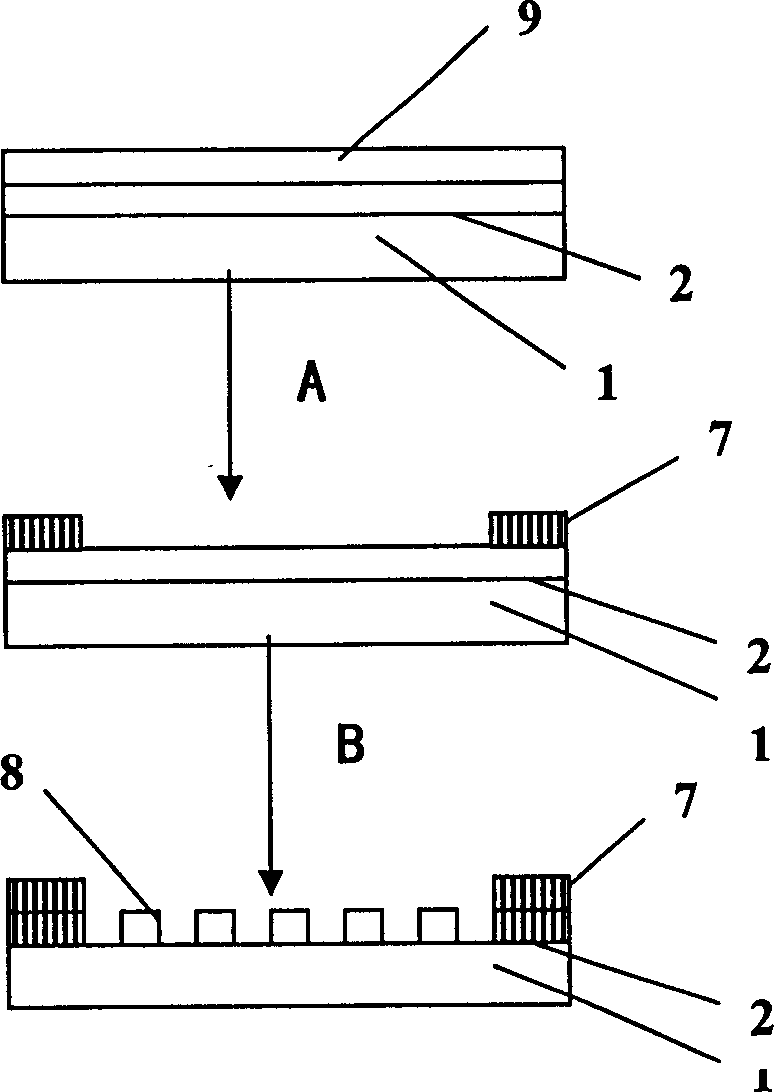

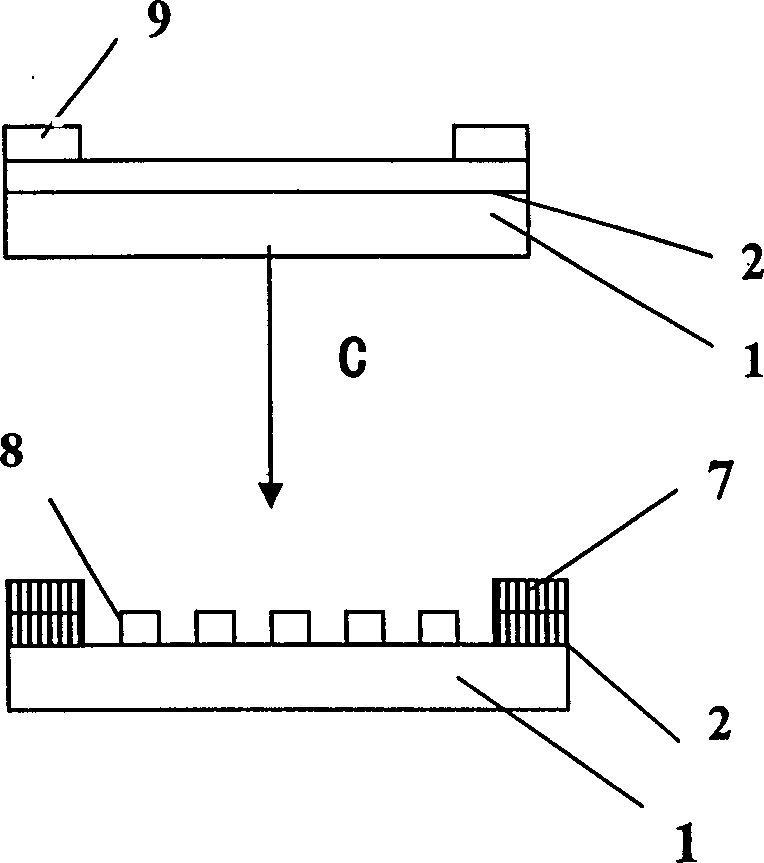

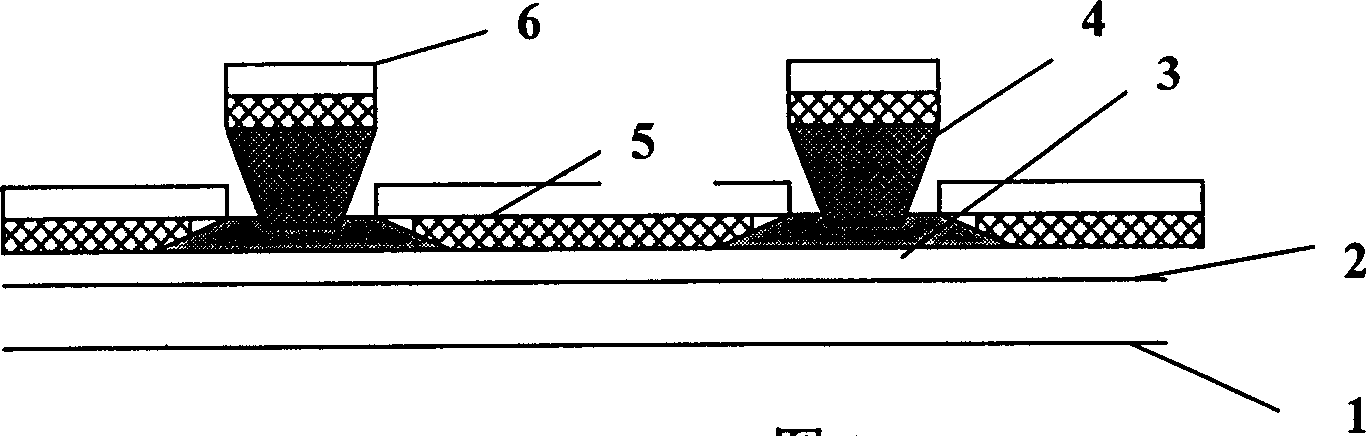

[0019] see figure 2 As shown, in the embodiment of the present invention, the steps of the manufacturing method of the transparent anode and the electrode lead wire of the organic light emitting display device are as follows:

[0020] Make a mask: Make a mask for metal sputtering according to the design plan;

[0021] Sputtering metal layer 9: use the mask plate to directly sputter the metal layer 9 of the required electrode lead-out line part on the glass substrate 1 of the ITO transparent conductive film 2 according to the technical indicators such as thickness and material; the electrode lead-out line is generally Use metals with excellent electrical conductivity, such as chromium, etc. This metal has strong adhesion to the ITO glass substrate, high firmness, and strong wear resistance. In addition, it can have high resolution. In addition, chromium has very good resistance to organic solvents; when it is necessary to form pixels The exposed areas of the lines must not h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com