Voltage reactive power integrated control device based on magnetic control reactor

A magnetically controlled reactor and comprehensive control technology, which is applied in reactive power compensation, reactive power adjustment/elimination/compensation, etc., can solve problems such as not involving comprehensive control, unfavorable installation and use, and large footprint, and achieve harmonic The effect of small current, lower overall cost, and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

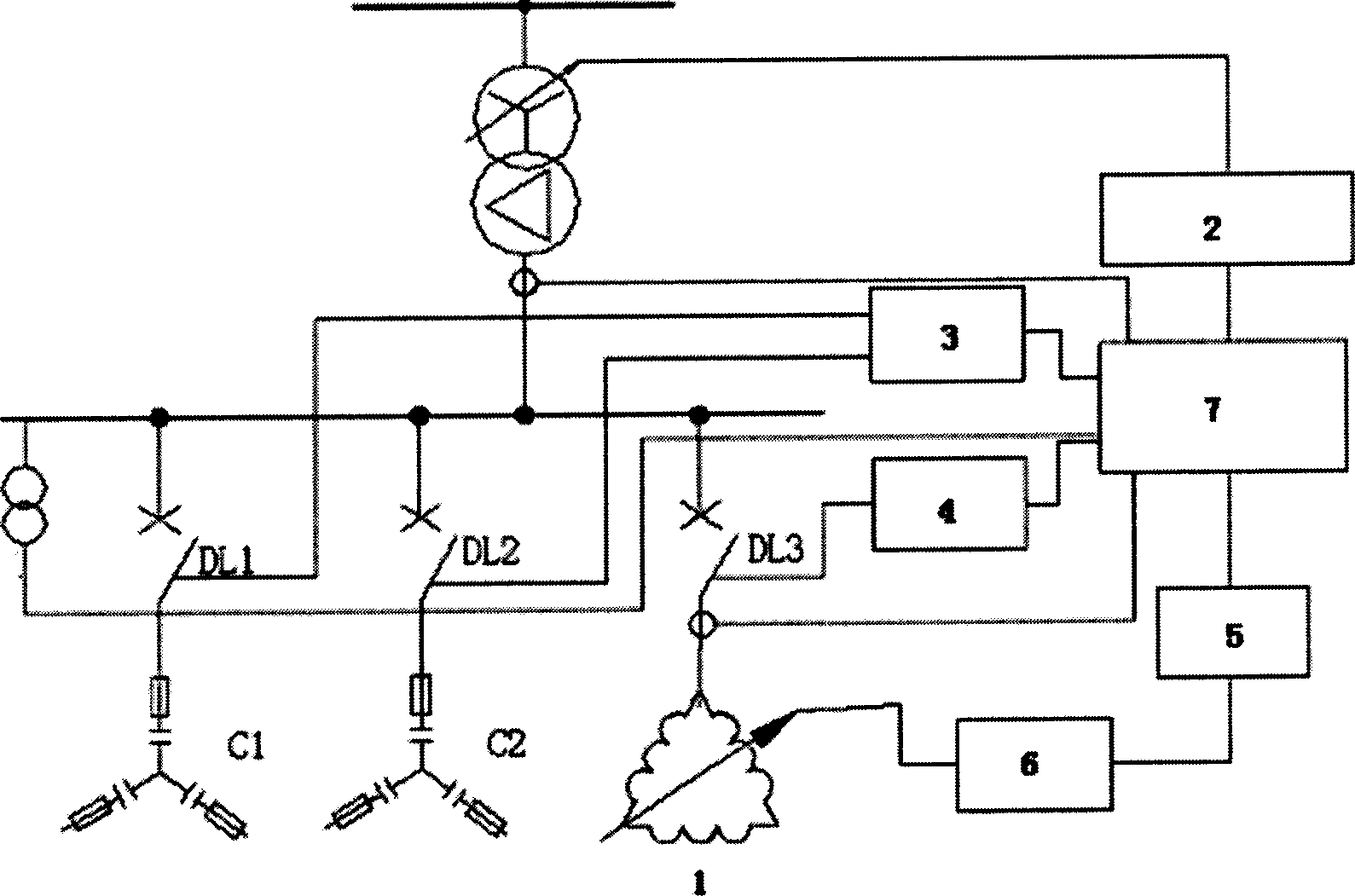

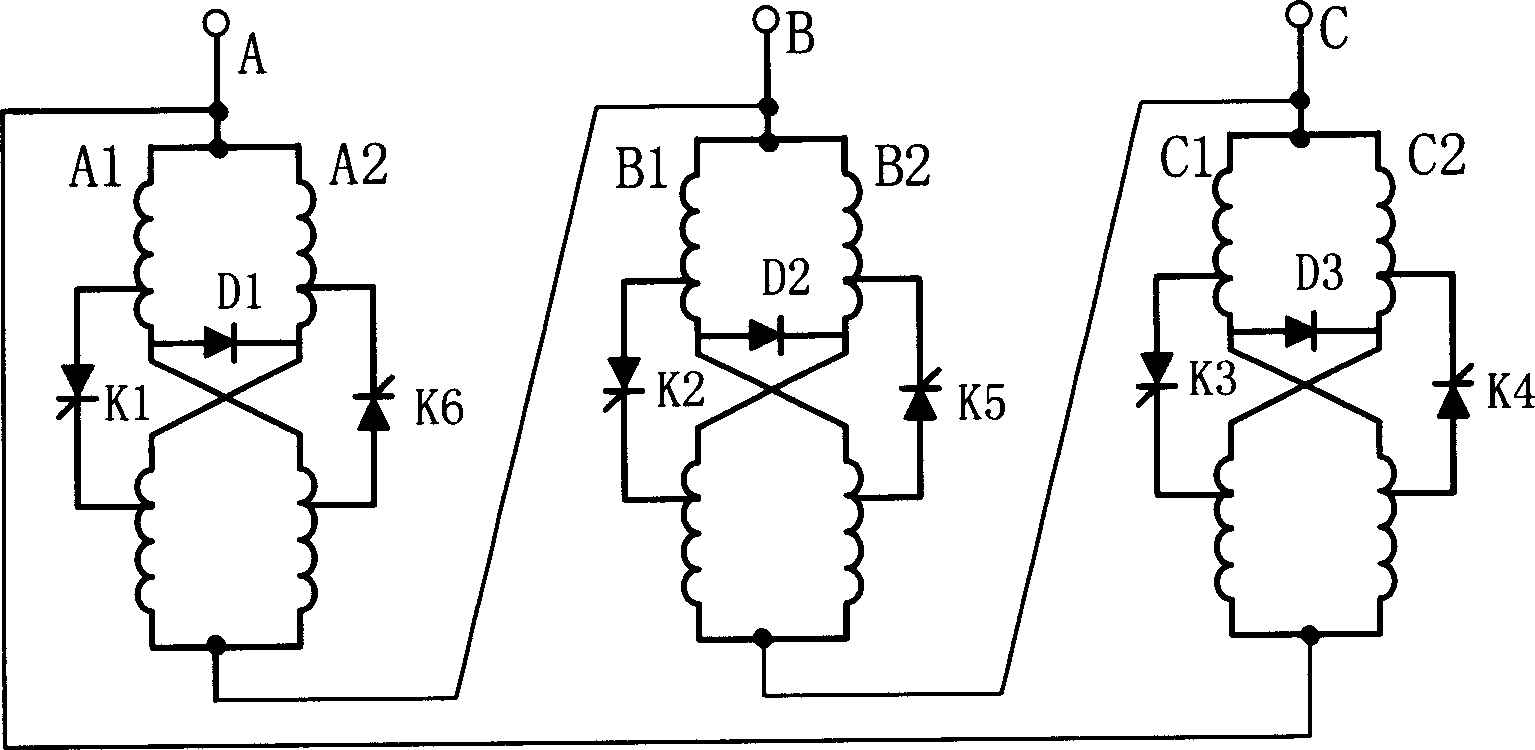

[0036] Such as figure 1 As shown, the present invention includes: three-phase six-column epoxy cast dry magnetron reactor (MCR) 1, main transformer on-load tap switch control module 2, capacitor switching module 3, reactor protection module 4, pulse electro-optical Conversion circuit 5, trigger control module 6, and intelligent control module 7. The connection relationship is: three-phase six-column epoxy cast dry-type magnetron reactor MCR 1 (hereinafter referred to as magnetron reactor 1) is connected in parallel with the capacitor bank on the low-voltage side bus of the transformer, and the main transformer on-load tap switch control module 2 is connected The on-load tap-changer to the main transformer is used to control the upshift or downshift of the on-load tap-changer. The trigger control module 6 is connected to the three-phase six-column epoxy cast dry-type magnetron reactor MCR 1, and controls the output capacity of the reactor. The pulse electro-optical conversion circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com