Optical fiber sculpture lamp and method for manufacturing the same

An optical fiber and lighting technology, applied in the field of optical fiber modeling lighting and manufacturing, can solve the problems of difficult production, short service life, high power consumption, etc., achieve the effect of increasing aesthetics, simple and durable production, and reducing production and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

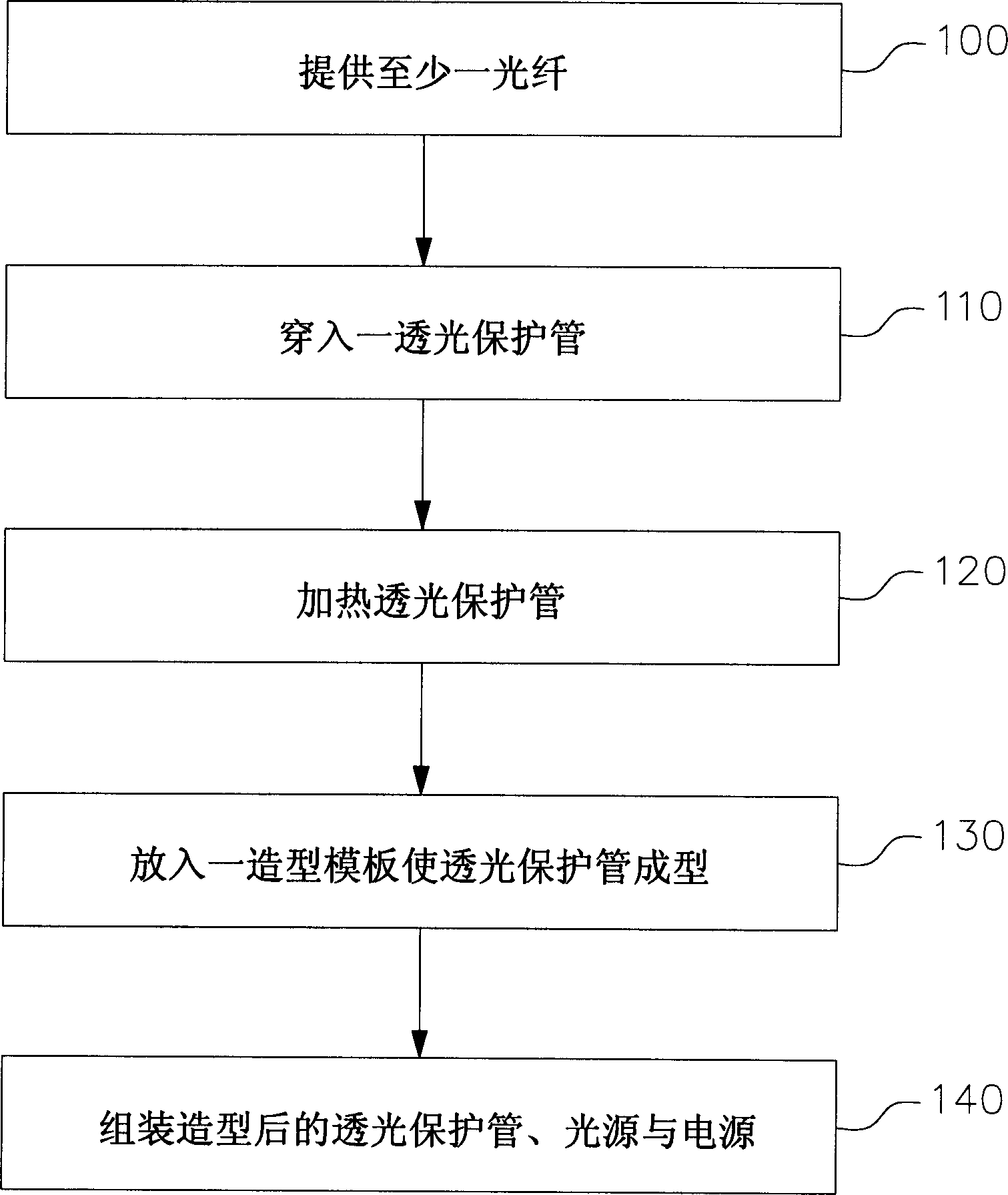

Method used

Image

Examples

Embodiment Construction

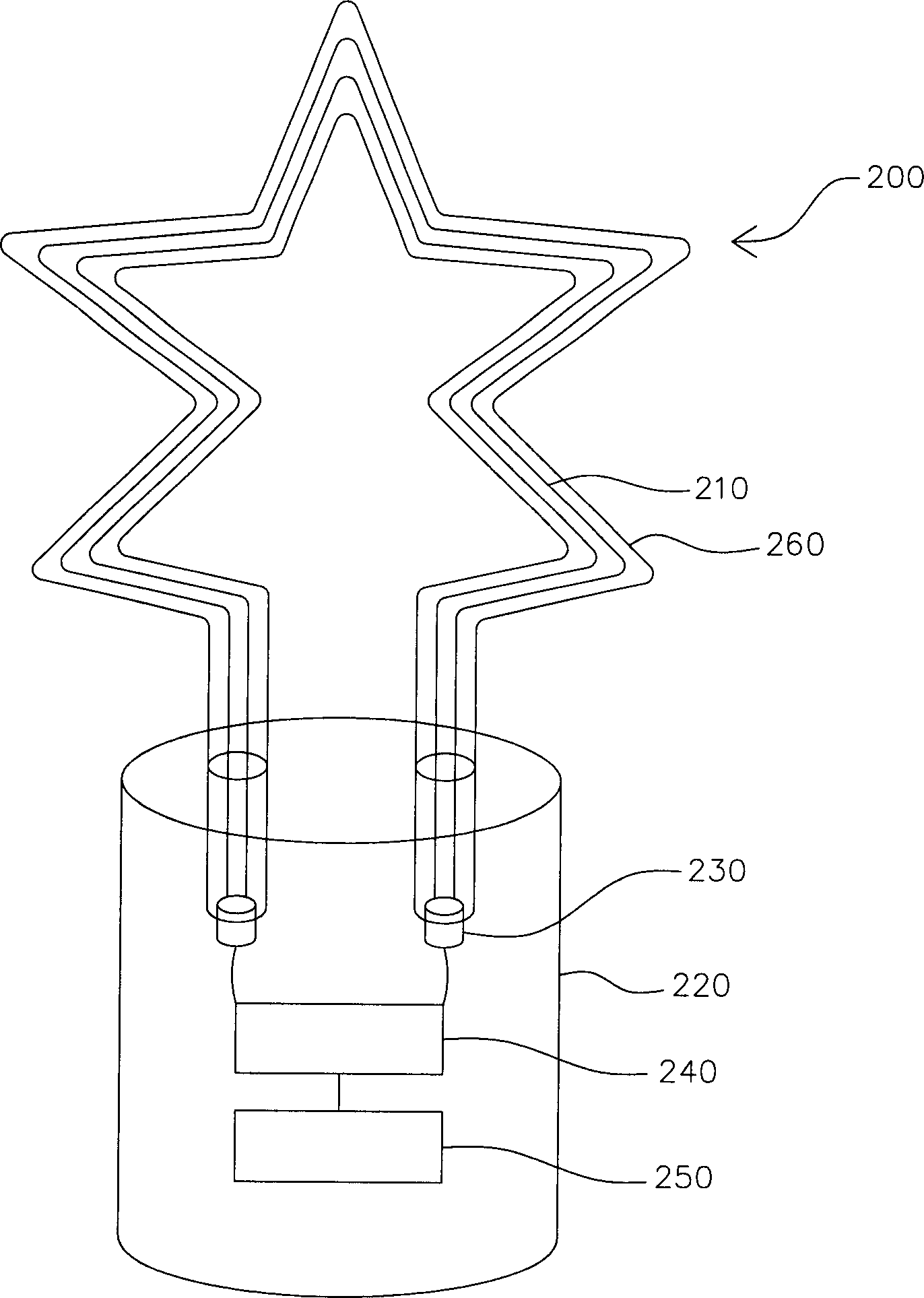

[0023] In order to make the above and other purposes, features, advantages and embodiments of the present invention more comprehensible, the detailed description is as follows according to the accompanying drawings:

[0024] The modeling lighting decoration of the present invention is not only easy to manufacture and install, but also can provide linear lighting modeling lighting decorations of different shapes according to the needs of users, and effectively reduces the power consumption of the modeling lighting decoration and increases the service life. The following will clearly illustrate the creative thought of the present invention with accompanying drawing and detailed description, as those who are familiar with this technology understand the preferred embodiment of the present invention, should be able to change and modify by the technology shown in the present invention, but this It does not depart from the creative thinking and protection scope of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com