Chemical fiber down strip and its production method

A chemical fiber and velvet technology, applied in the field of online twisted velvet and its manufacturing, can solve problems such as being unsuitable for mass production, low production efficiency, and difficult to adapt to supply and demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

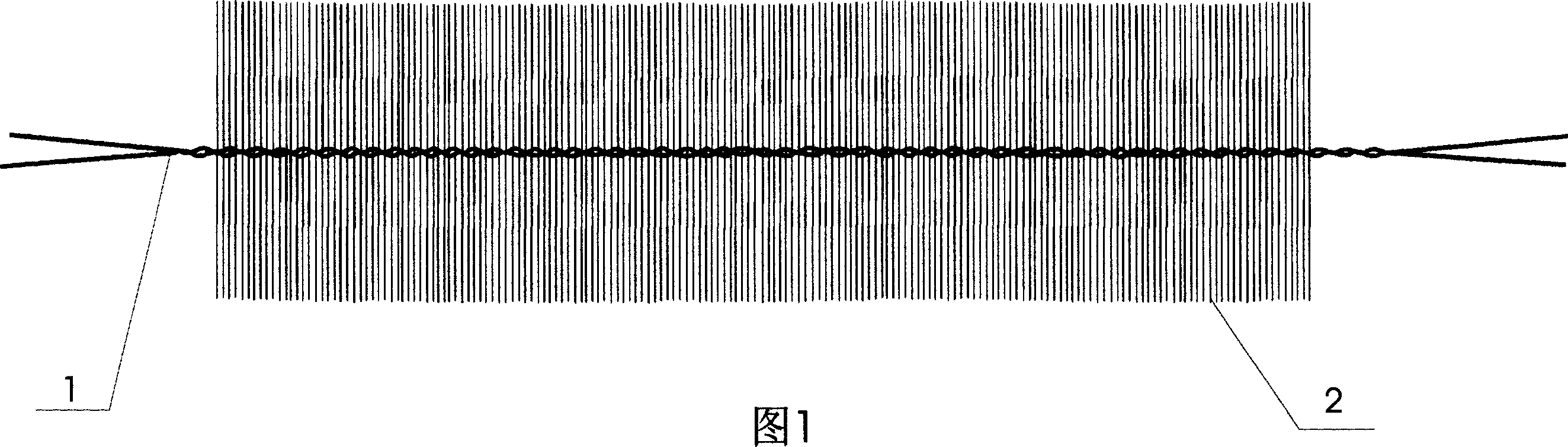

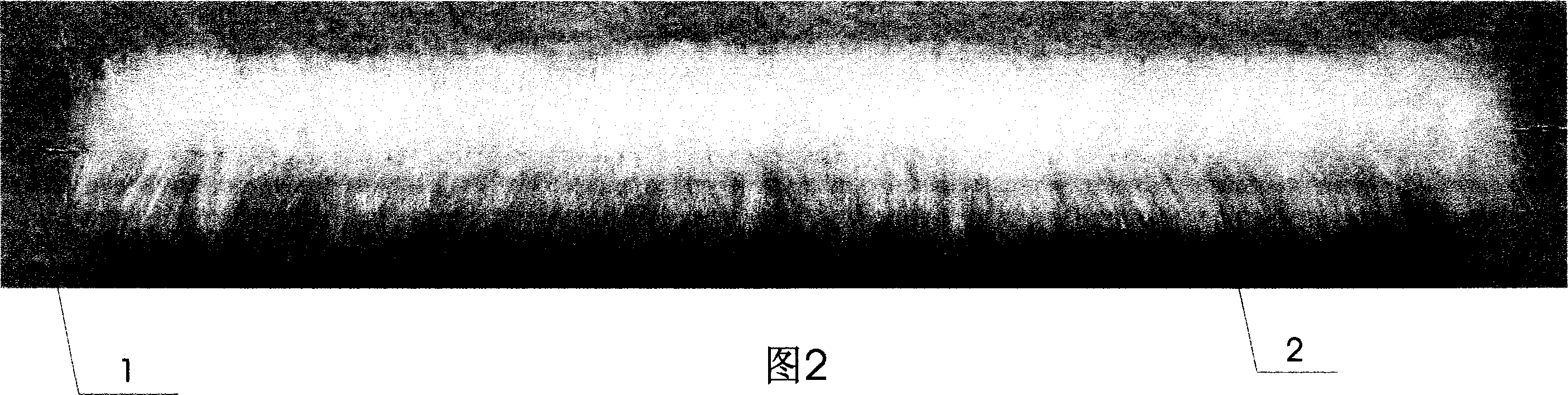

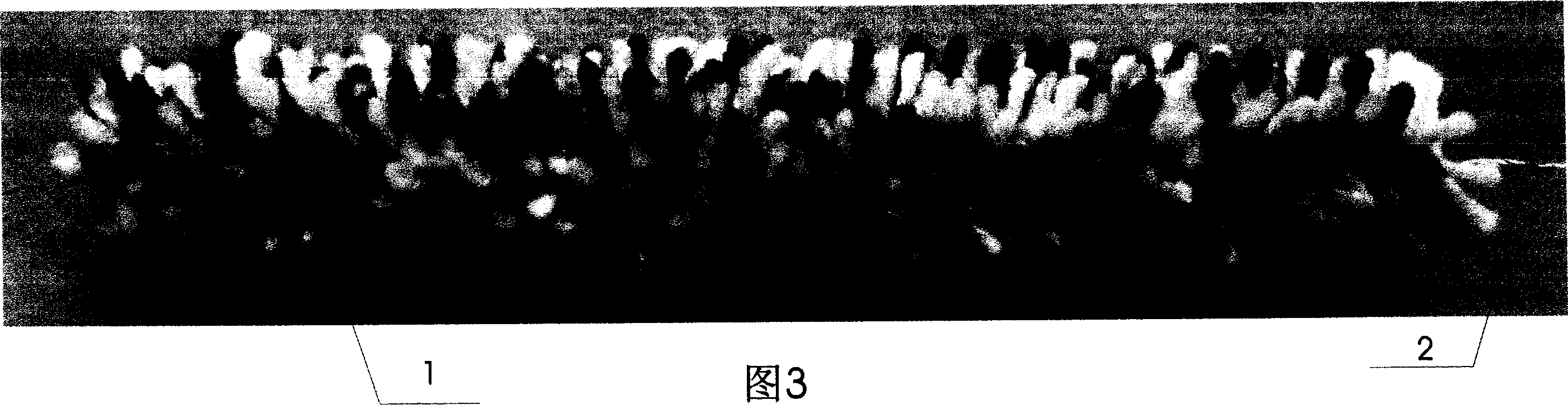

[0022] The purpose of the present invention is to provide a chemical fiber pile and its manufacturing method, which adopts semi-steel wire, copper wire, iron wire, chemical fiber yarn and other thread materials and PP chemical fiber, nylon chemical fiber, polyester chemical fiber, PVC chemical fiber, wool, industrial bonding Agent or water-based resin, PET onion silk, woolen thread as materials. It is made through five processes: outer fleece production, inner line racking, outer flocking racking, machine winding and racking.

[0023] The production of the chemical fiber pile of the present invention mainly involves five processes: outer pile production, inner wire racking, outer pile racking, machine winding, and racking. The specific implementation is as follows:

[0024] The first step is the production of outer fleece: use PP chemical fiber, nylon chemical fiber, polyester chemical fiber, PVC chemical fiber, and PET chemical fiber raw materials to be processed into PP chemical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com