Round rod feeding device on steel bar cutter

A technology of steel bar cutting machine and blanking device, which is applied to shearing devices, accessories of shearing machines, shearing machine equipment, etc. The effect of quality, low manufacturing cost and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] [specific implementation]

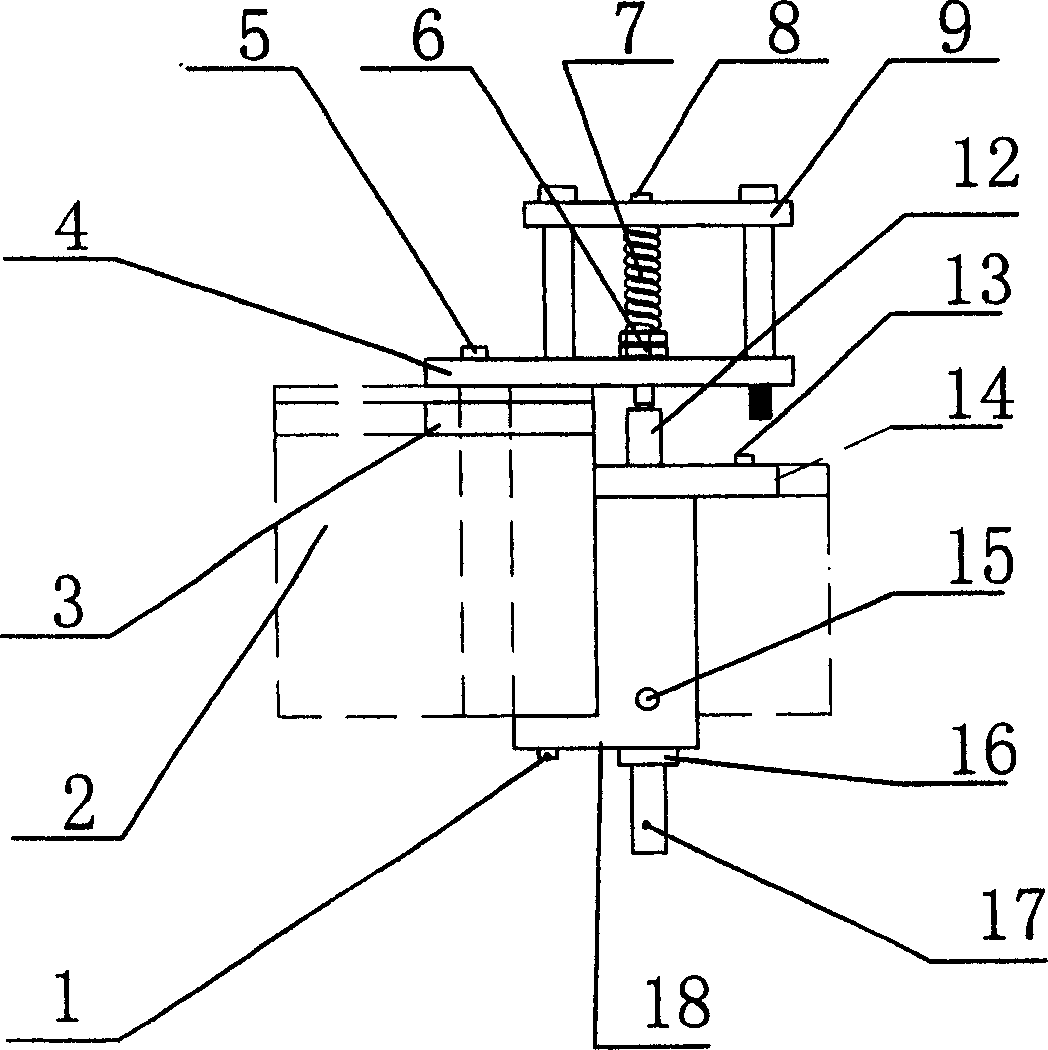

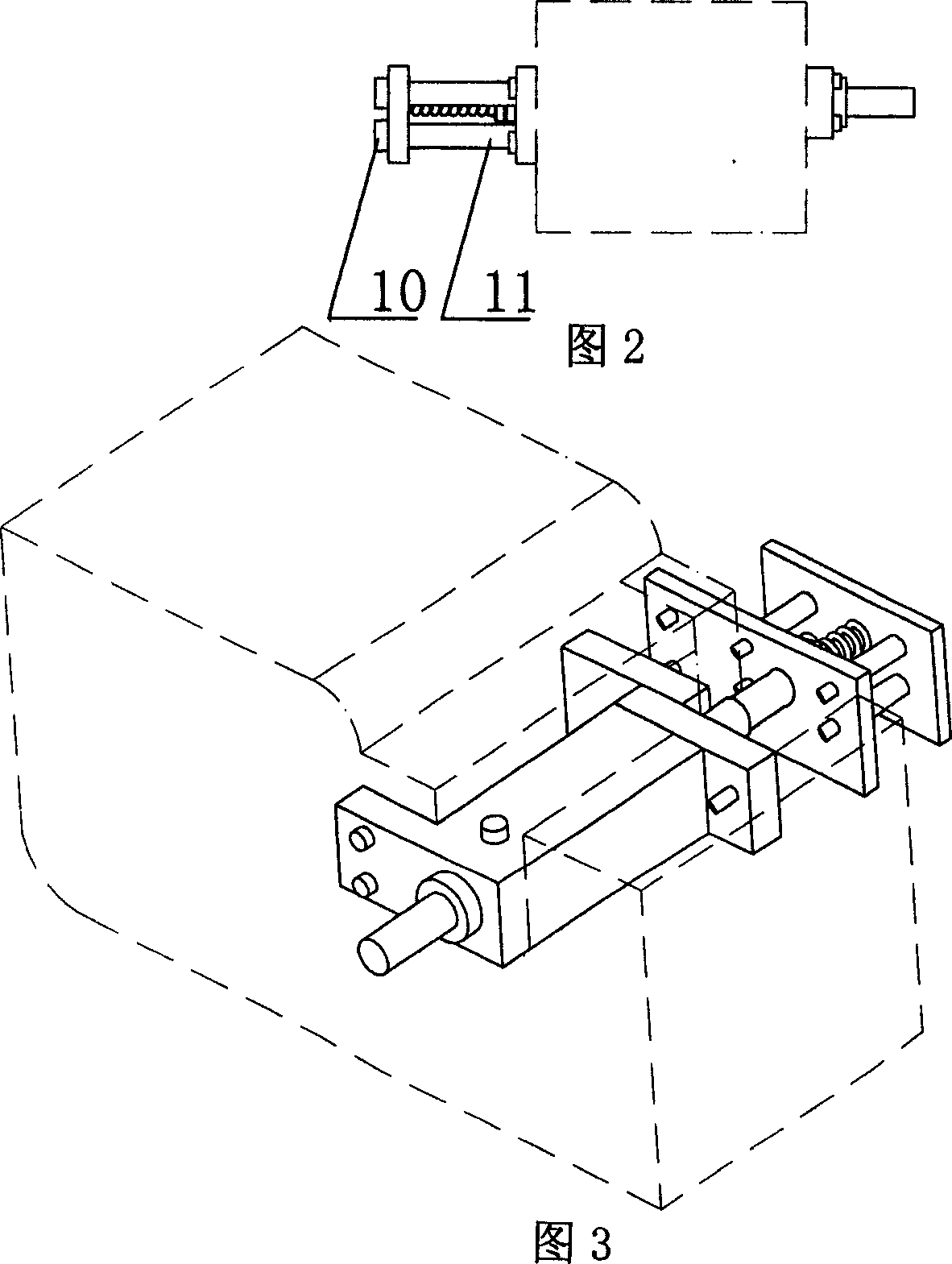

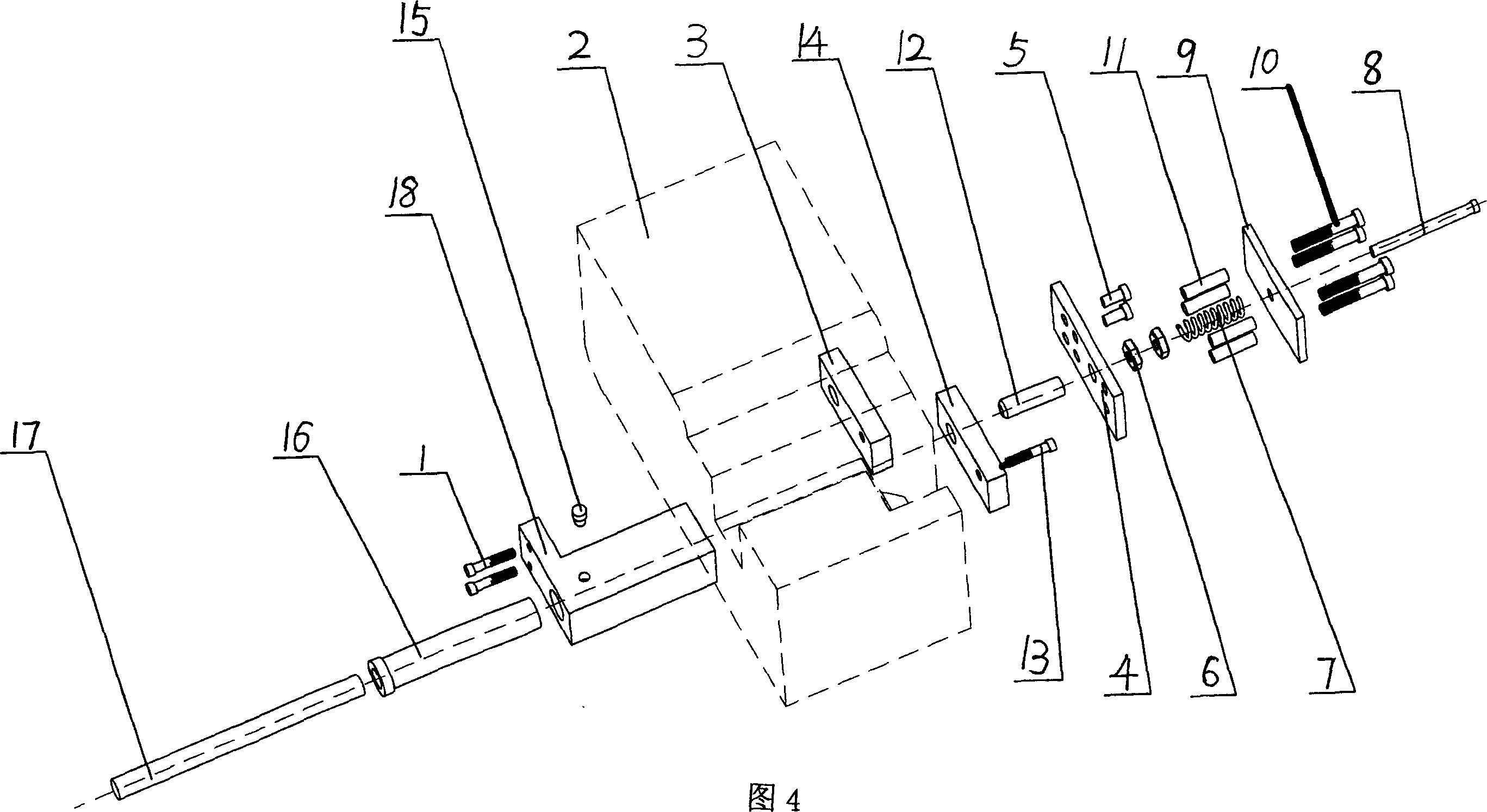

[0014] Referring to Fig. 4, there is a groove 19 on the upper end surface of the cutting machine base 2, and a guide seat 18 is installed in the groove 19, and the guide seat 18 is fixedly connected to the cutting machine base 2 by screws 1, and a round hole is opened inside the guide seat 18 , guide sleeve 16 is housed in the round hole, and guide sleeve 16 adopts head screw 15 to be fixedly connected on the guide seat 18, and guide sleeve 16 rear end is equipped with fixed knife plate 14, and fixed knife plate 14 adopts screw (13) to be fixedly connected on cutting On the machine base 2, the fixed knife plate 14 has a round hole at the position matched with the guide sleeve 16, the fixed knife plate 14 is matched with the movable knife plate 3, and the movable knife plate 3 is provided with a semicircular concave hole at the corresponding cutting position. Groove, fixed distance support 4 adopts screw 5 to be fixedly connected on the rear e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com