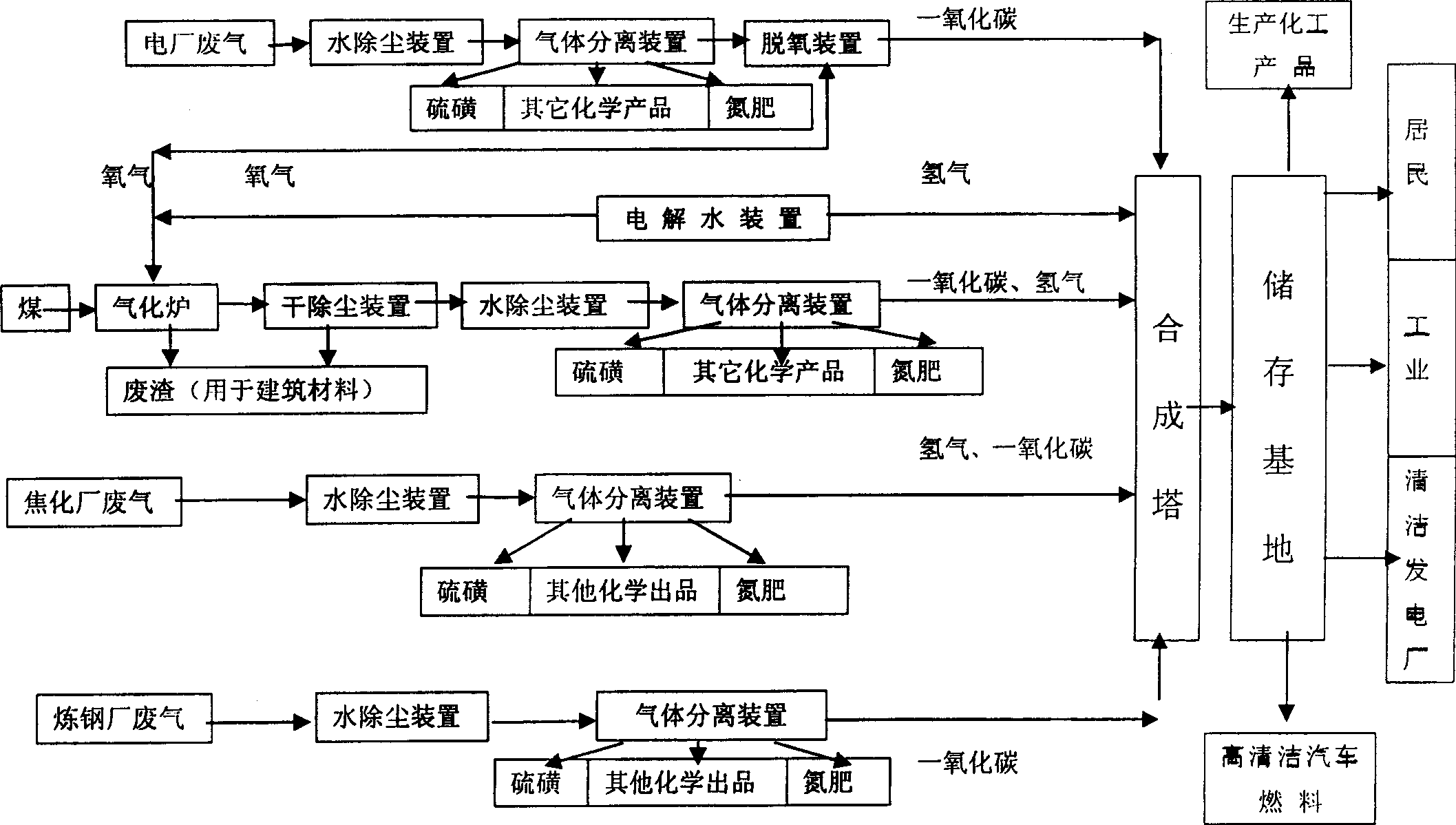

Process of co-producing high clean fuel by adding hydrogen to coal gasifying, power plant or other industrial waste gas

A technology of coal gasification and clean fuel, applied in the direction of mixed gas modification with other gases, gas fuel, fuel, etc., can solve the problems of waste and low utilization efficiency, and achieve the effect of saving coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] craft (1)

[0024] Coal gasification, power plant or other industrial waste gas mixed with hydrogen to produce high-clean fuel power generation, residential and industrial use, or as a high-clean vehicle fuel and production of chemical products, is the use of coal gasification to produce crude gas and process crude gas , so that the typical gas composition contains more than 65% CO and H 2 More than 30%, the use of power plants or other industrial waste gas CO 2 Preparation of O 2 and CO, or use CO directly 2 Add hydrogen to produce high-clean fuel; the high-clean fuel contains about 33% CO and H 2 Around 66%. This fuel is used for power generation in power plants, residential and industrial use, or as high-clean vehicle fuel and production of chemical products.

[0025] craft (2)

[0026] Production of rich H by using coke oven gas 2 and low-CO gas, mixed with CO or coal gasification to synthesize high-clean fuel; use steelmaking waste gas to produce CO-rich and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com