Thin digit camera

A digital camera and thin-shape technology, applied in the field of digital cameras, can solve the problems that digital cameras cannot be miniaturized, and achieve the effect of thinning and reducing the thickness in the Z direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

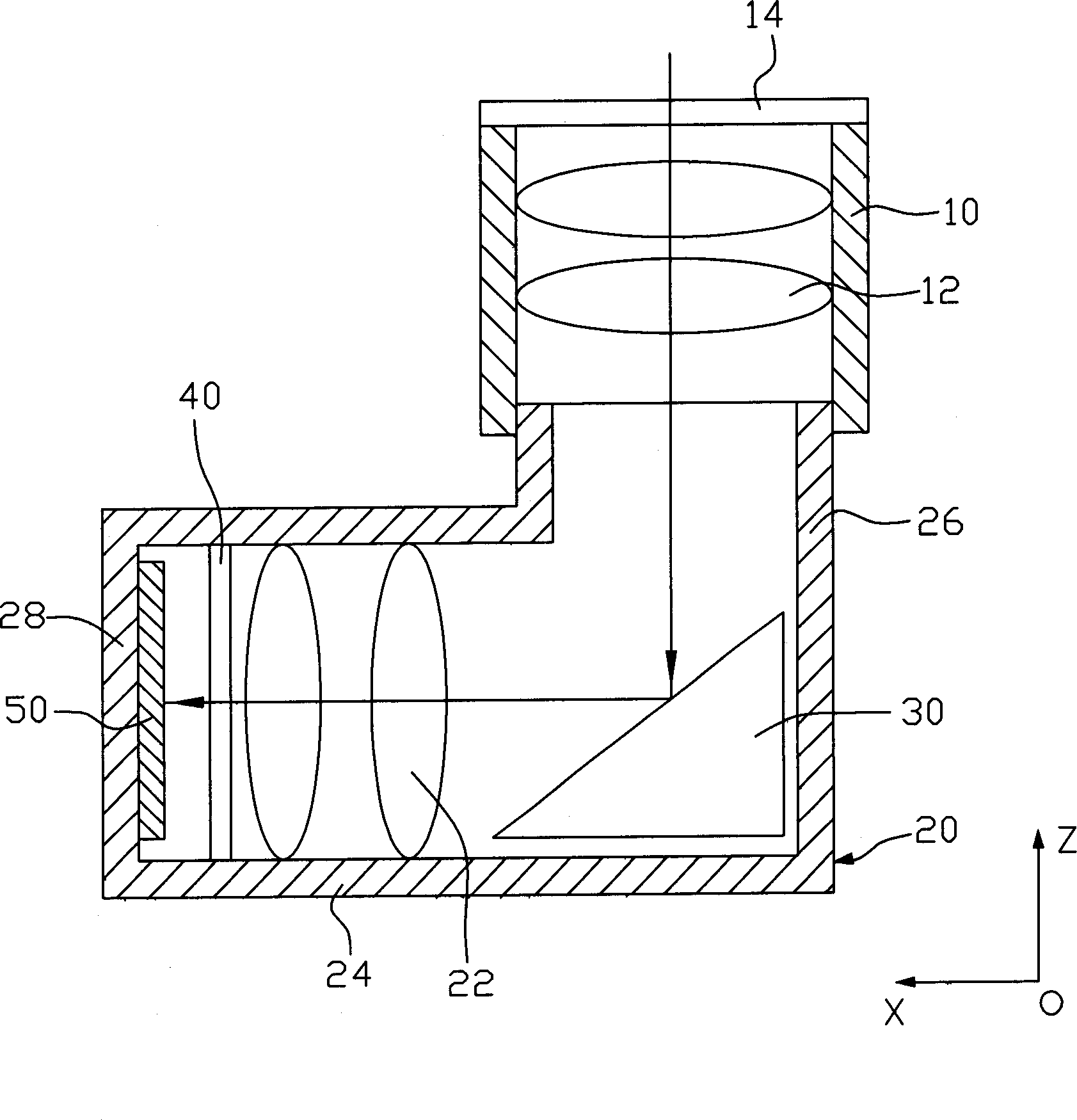

[0009] See figure 1 , the thin digital camera of the present invention includes a first lens barrel 10 , a second lens barrel 20 , a beam splitter 30 , an infrared filter 40 , and an image sensing element 50 .

[0010] The first lens barrel 10 is cylindrical, and houses a first lens group 12 therein. The first lens group 12 is composed of a plurality of lenses, which first contact the light entering the camera from the outside and focus the light. The first lens barrel 10 is located in the Z-axis direction. In order to protect the first lens group 12, a glass plate 14 is provided in front of the first lens group 12. The glass plate 14 is used to protect the first lens group 12 from avoiding In addition to scratches, it also prevents dust from entering.

[0011] The second lens barrel 20 is equipped with a second lens group 22, and the second lens group 22 is composed of a plurality of lenses. The second lens barrel 20 includes an accommodating portion 24 , a connecting porti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com