Rotary and sliding fire grate air conditioner of chain

A technology of chain grate and air regulating device, which is applied in valve configuration, combustion air/fuel supply, combustion method, etc., can solve the problems of serious fly ash, affecting the thermal load and thermal efficiency of the boiler, and low wind pressure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

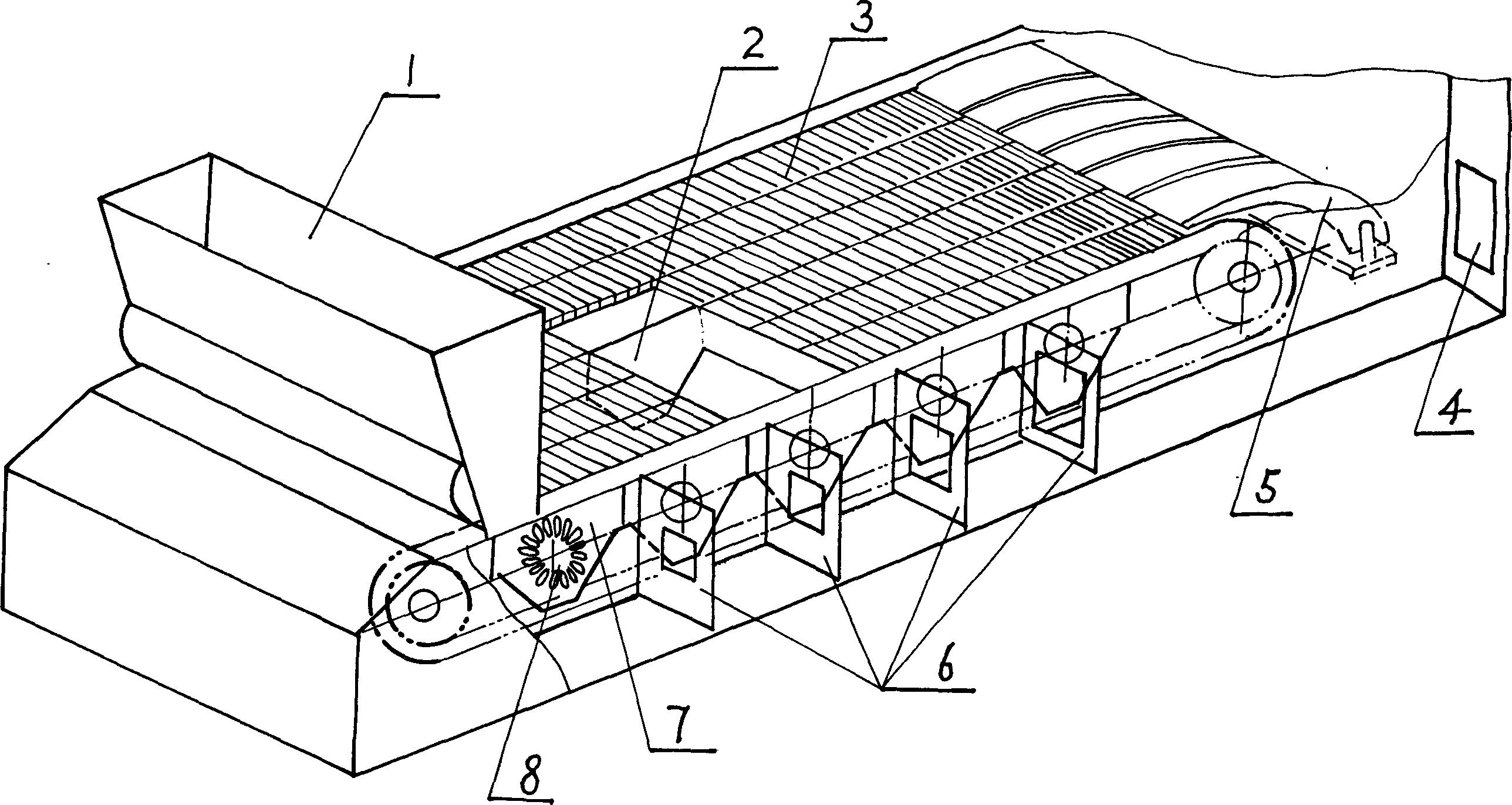

[0017] see figure 1 , is a schematic diagram of the position and structure of the present invention, and each label in the figure is respectively represented as: Coal drop hopper 1, wind shielding plate 2, chain grate 3, air inlet channel 4, slag retainer 5, air volume regulating plate 6, air chamber 7 , air inlet 8.

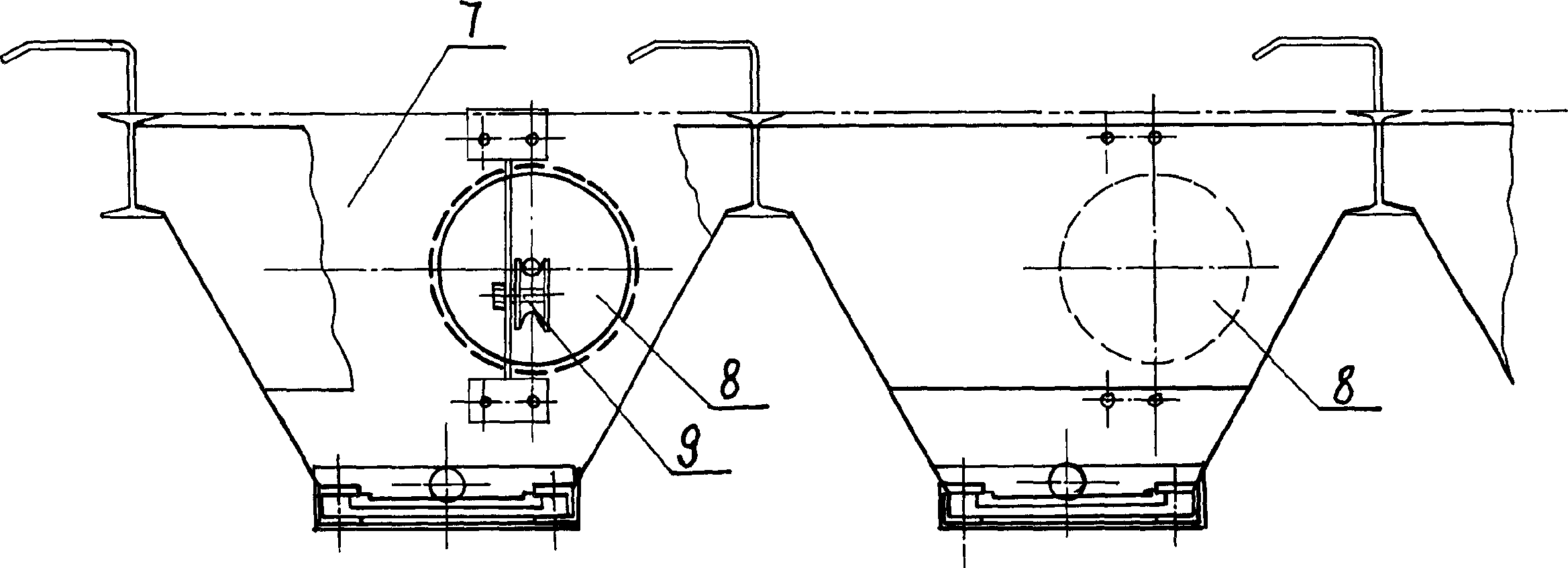

[0018] see figure 2 , is a schematic diagram of the structure of the air chamber 7, at the air inlet 8 of the air chamber, a damper air regulating assembly 9 is arranged.

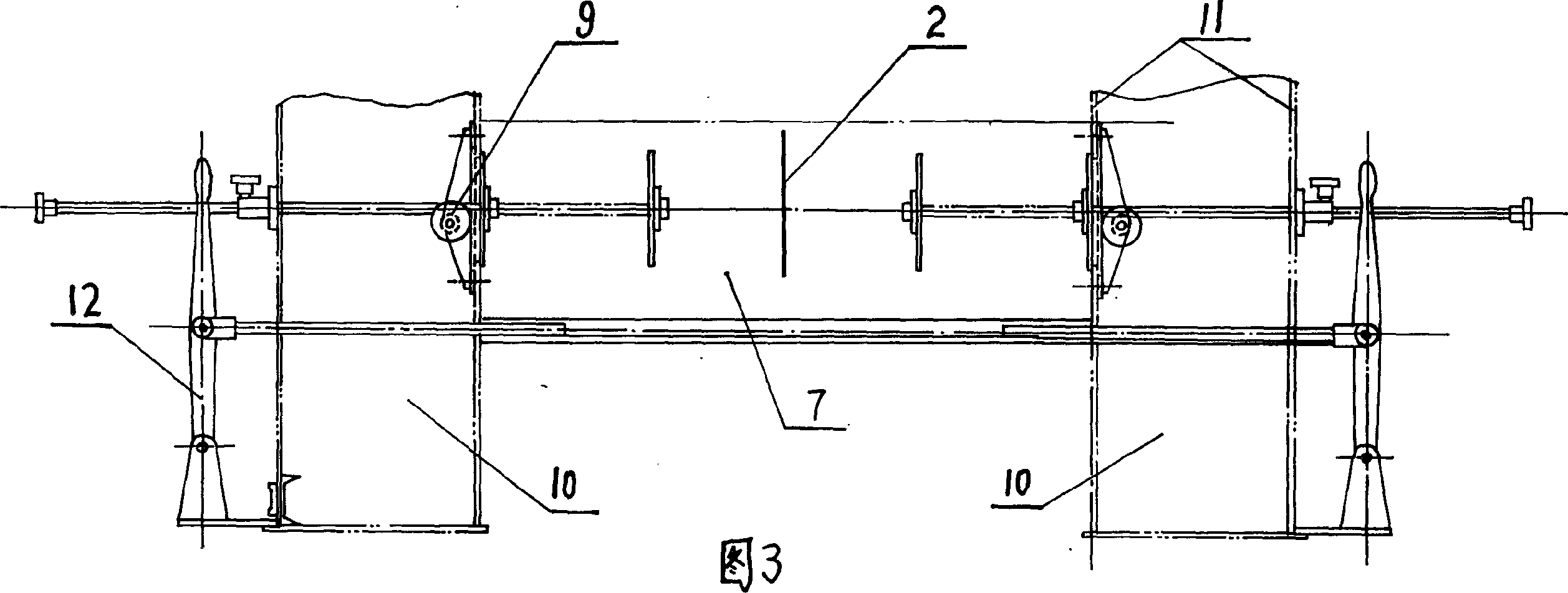

[0019] In the rotary push-pull chain grate air distribution and air conditioning device of the present invention, the grate air distribution has five air chambers 7, and the air inlets 8 of each air chamber adopt the shape of a round hole with the minimum wind flow resistance, and can also be used Circular petal-shaped or elliptical petal-shaped hole structure, the air inlet 8 with circular or petal-shaped hole structure can increase the cross-sectional area of the air inlet by 2.58 time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com