Vertical heat tube cooling machine

A cooler and heat pipe technology, applied in vertical heat pipe coolers, F28C 3/12 category, can solve the problems of difficult recycling of waste heat, high air leakage rate and energy consumption, and high mechanism failure rate, so as to achieve less environmental pollution and reduce Effect of air leakage and reduction of process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

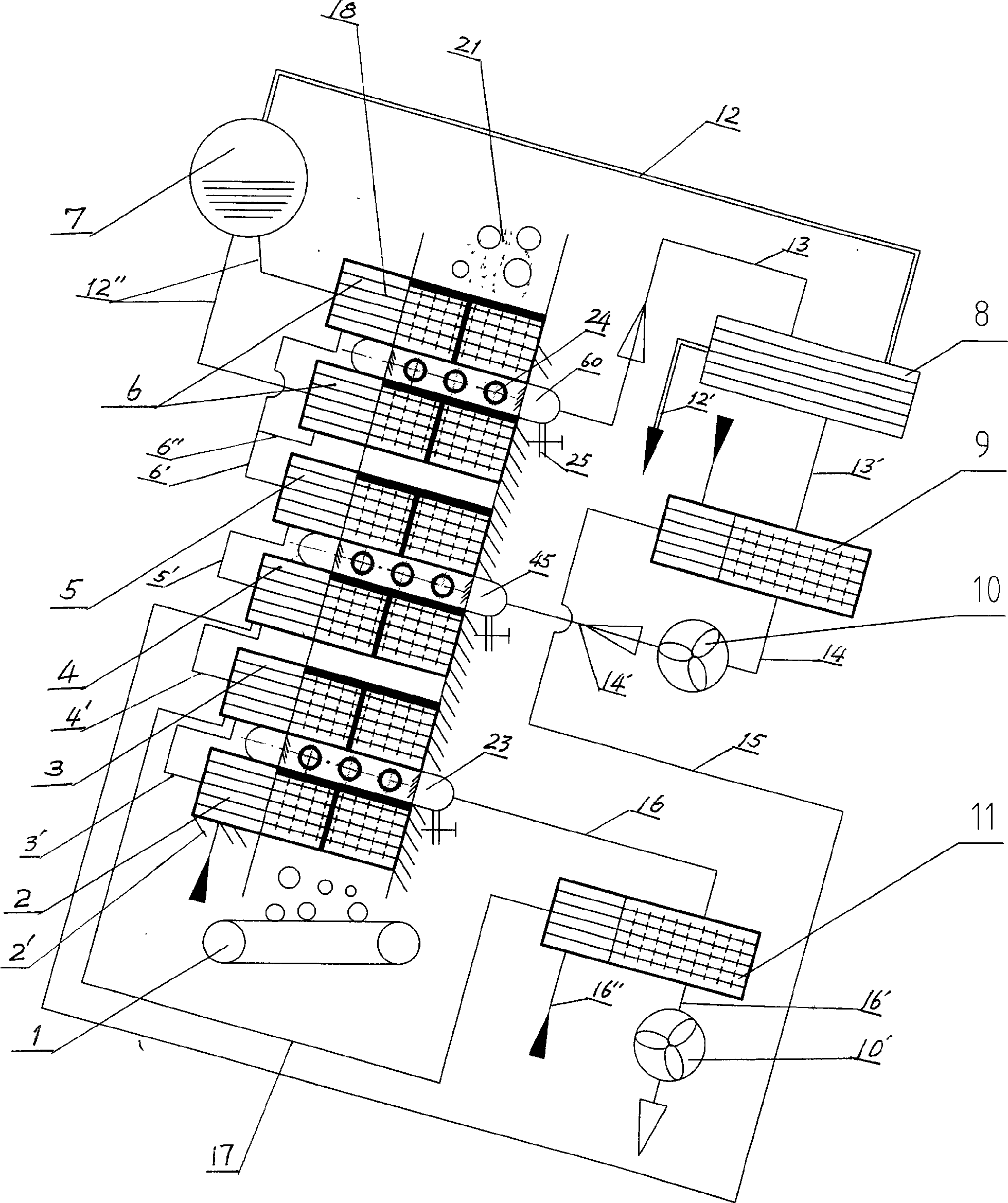

[0018] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

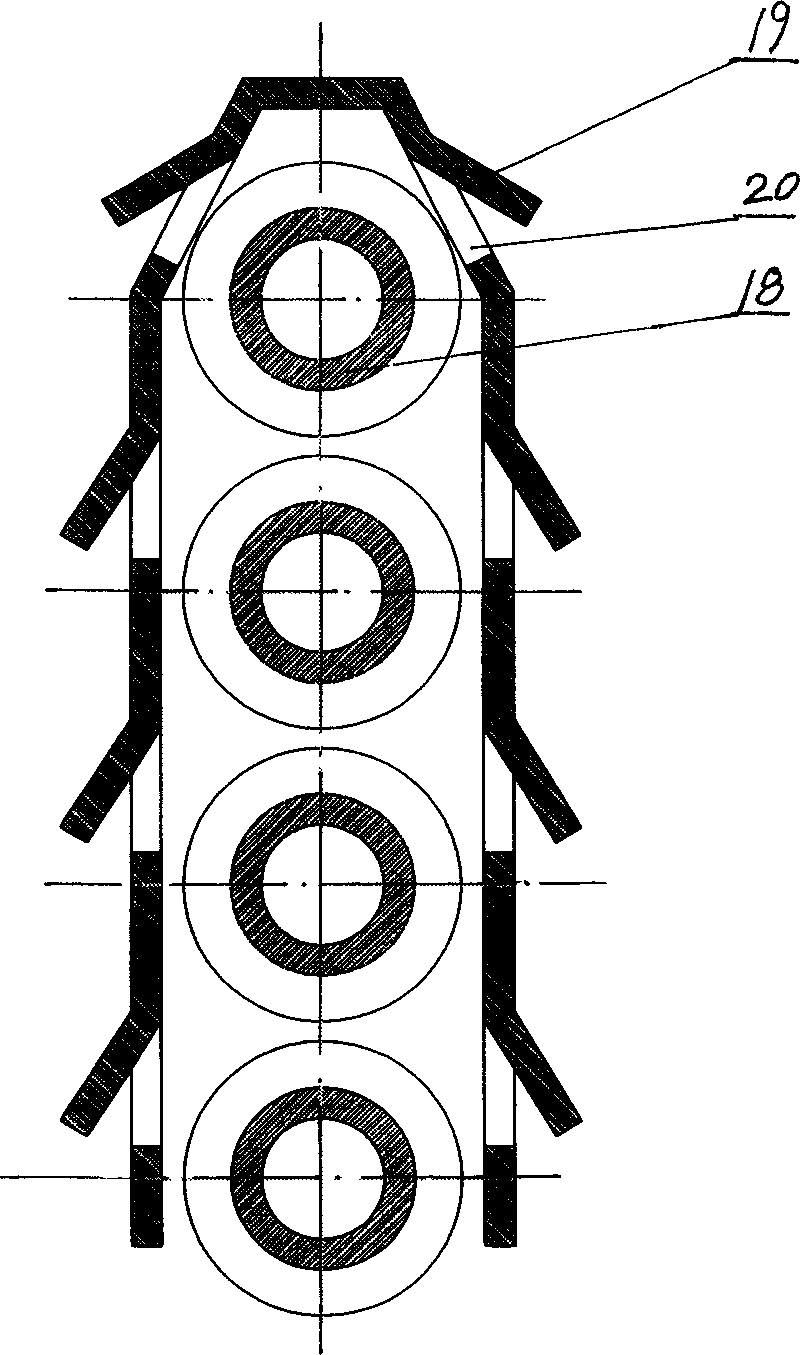

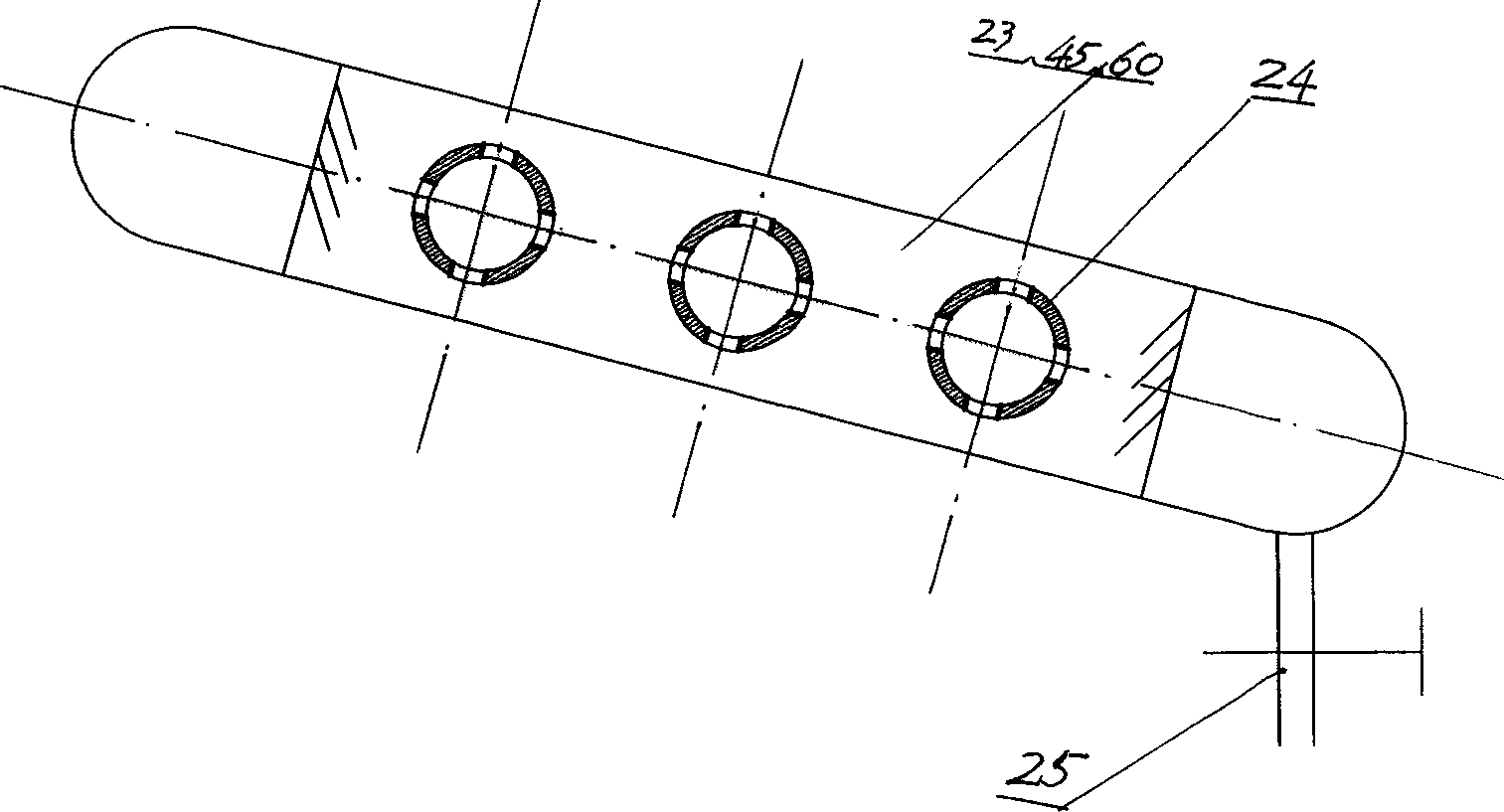

[0019] As shown in the drawings, the vertical heat pipe cooler is composed of a cold ore discharge chain plate machine 1, a fixed support 2', a low-temperature heat pipe preheater 2, a heat pipe preheater 3, and a medium-temperature heat pipe preheater 4 , high-temperature heat pipe preheater 5, heat pipe evaporator 6, annular air duct 23 or 45 or 60, steam drum 7, steam superheater 8, flue gas heat pipe preheater 9 or 11, fan 10 or 10', soft water pipe 3 ' or 4' or 5' or 6' or 16" or 15 or 17, steam pipe 12 or 12", steam delivery pipe 12', air pipe 13 or 13' or 14 or 14' or 16 or 16', The low-temperature heat pipe preheater 2, medium-temperature heat pipe preheater 4, high-temperature heat pipe preheater 5, and heat pipe evaporator 6, which are composed of heat pipes 18, are arranged sequentially from the bottom up. He...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com